Image sensor and method of forming the same

An image sensor and filter technology, used in semiconductor devices, electrical solid state devices, radiation control devices, etc., can solve the problems of underexposure, insufficient dynamic range of the image sensor, overexposure of the output image, etc., to prolong the exposure time, improve the Image quality, the effect of improving the dynamic range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

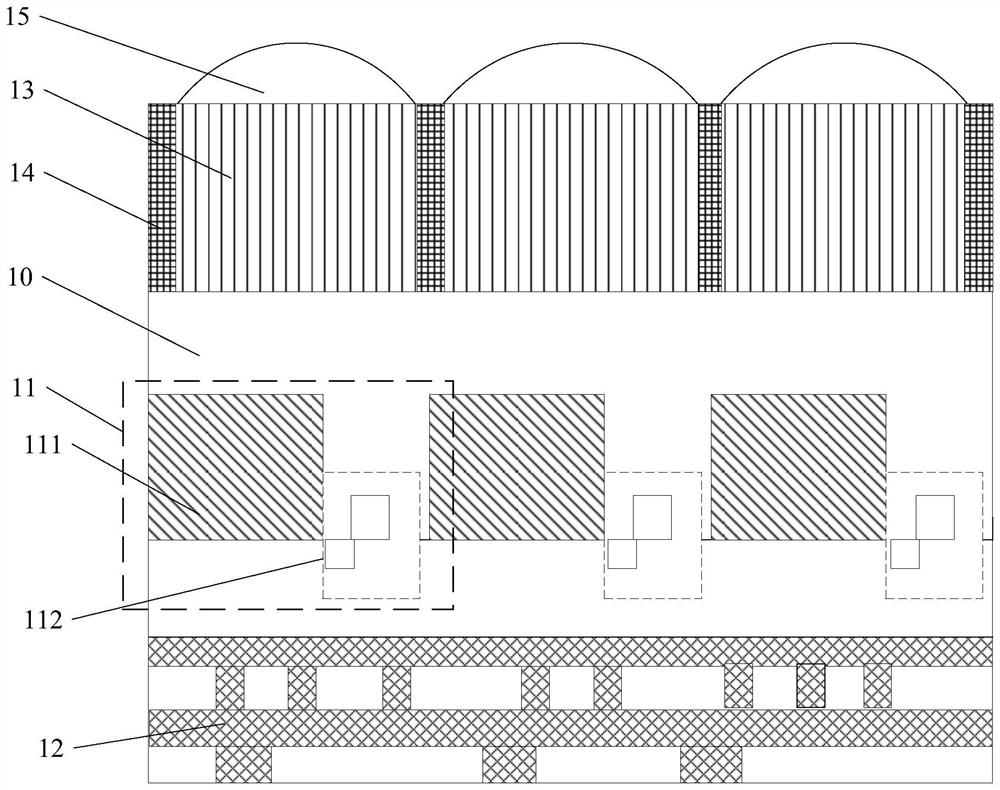

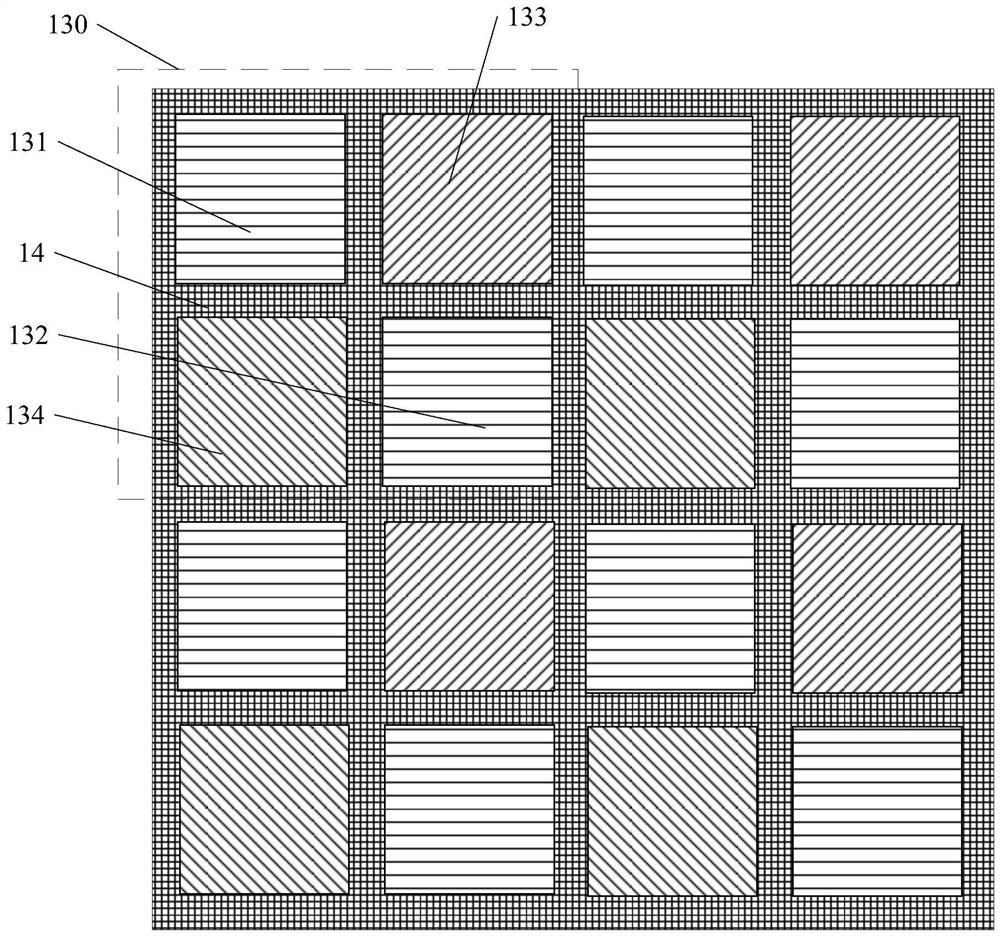

[0028] In the prior art, the optical filter matrix includes a plurality of minimum repeating units, and the optical filter matrix may be, for example, a Bayer array, a mosaic sequential array or other pattern arrays.

[0029] In the filter matrix, more green filters are generally arranged, so in order to improve the image quality output by the image sensor, the photoelectric response performance of the green filter should be improved as much as possible. Taking the Bayer array as an example, the green filter contained in the minimum repeating unit is twice as many as the red filter or the blue filter, and the green filter is alternately embedded in the adjacent row between the blue filter between or between red filters.

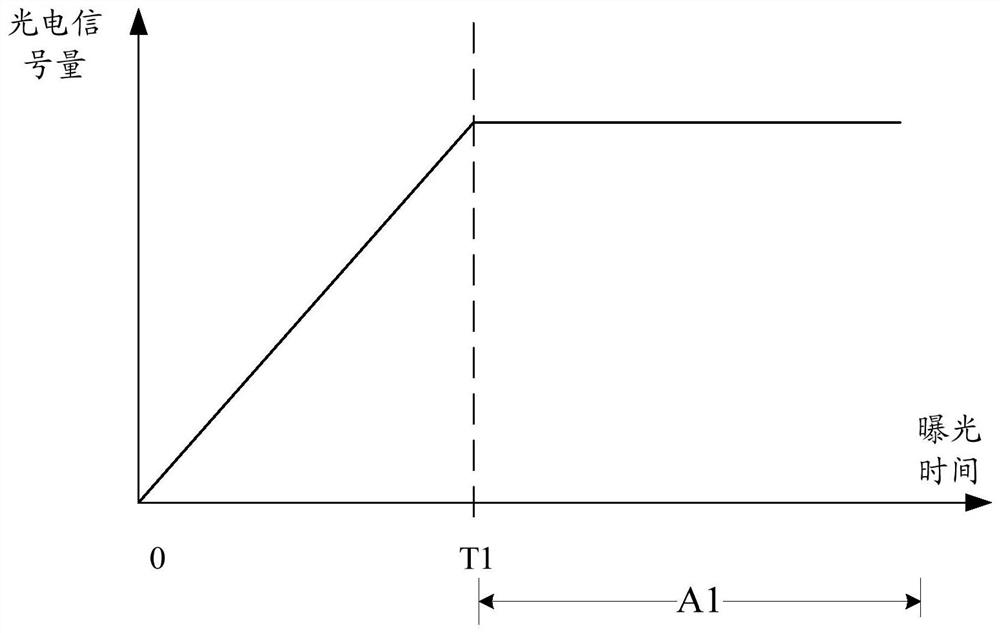

[0030] figure 1 It is a schematic diagram of a photoelectric response curve of a green filter of an image sensor in the prior art.

[0031] like figure 1 As shown, the horizontal axis is the exposure time under a fixed light intensity environment, the long...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com