Touch control display substrate, manufacturing method therefor, and display device

A technology for a touch display substrate and a manufacturing method, which is applied in semiconductor/solid-state device manufacturing, instrumentation, electrical digital data processing, etc., and can solve problems such as low light transmittance, thick display device, large display area and touch blind area, etc. Achieve the effect of improving touch precision, realizing narrow frame and large size, and ensuring uniform design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

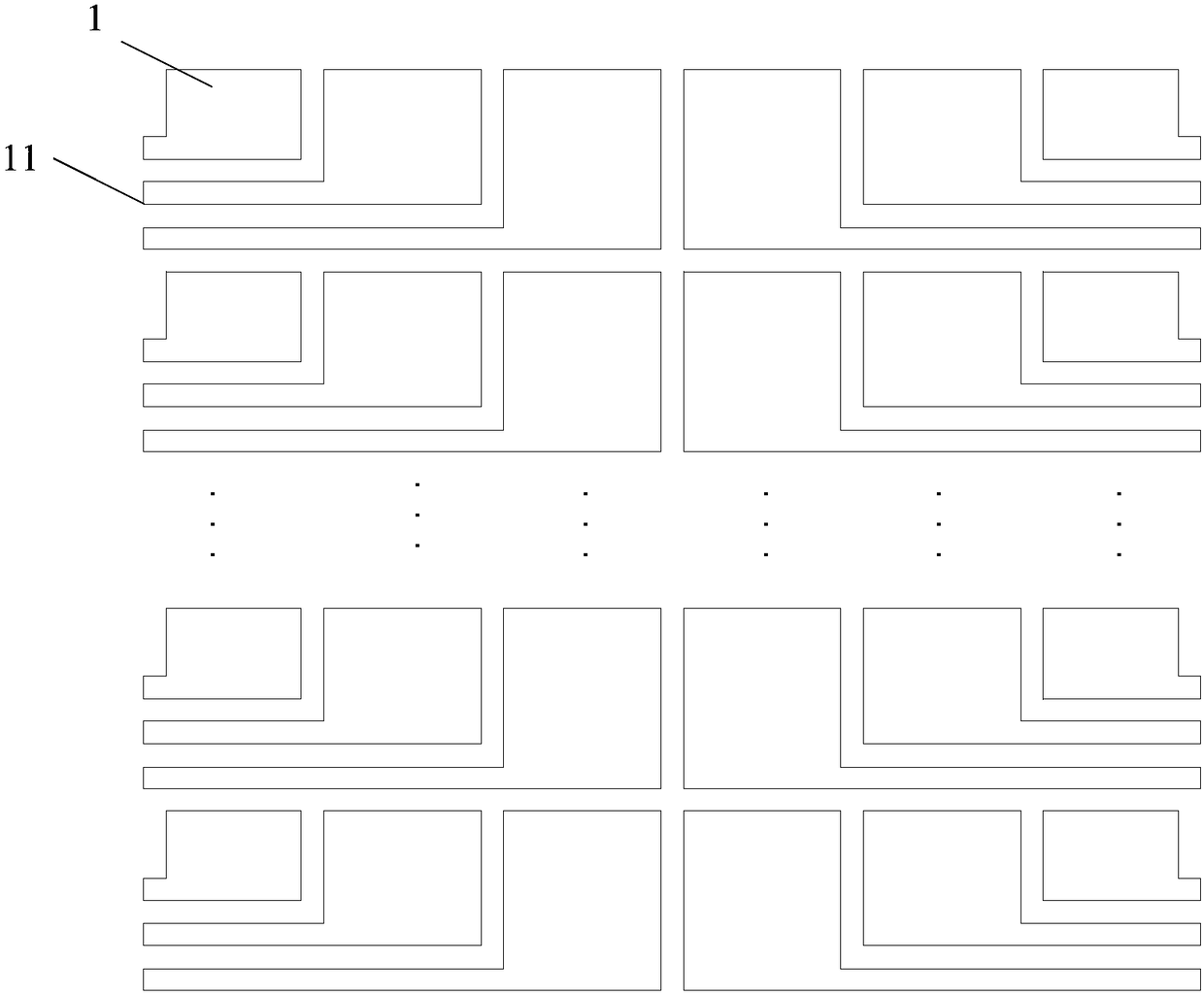

[0062] In the prior art, in order to reduce the thickness of the OLED touch display device, the cathode of the OLED touch display device is multiplexed as a touch electrode, but since it is difficult to form a via hole penetrating through the common layer, as figure 1 As shown, the touch electrodes 1 are all led to the periphery of the display area through traces 11, and then connected to the touch signal lines below the common layer through vias located around the display area. In the wiring area, as the size of the touch display device increases and the number of touch electrodes increases, the area of the surrounding wiring area will also increase, resulting in a relatively large touch blind area around the display area, which is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com