Polymeric sorbents for reactive gases

A reactive gas, adsorbent technology for gas treatment, alkali metal compounds, greenhouse gas capture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and 2

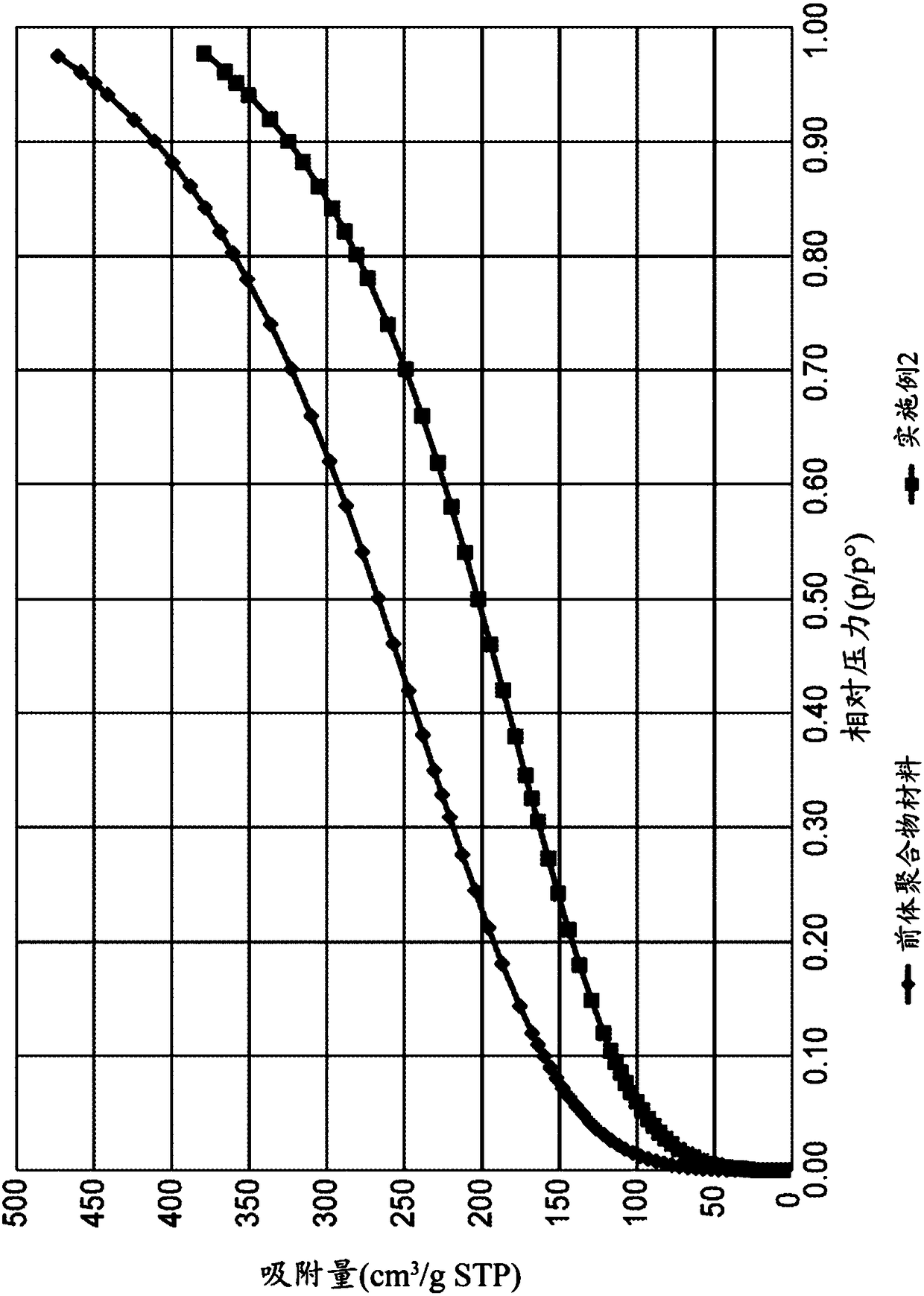

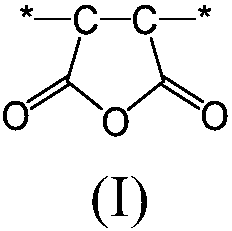

[0369] In a 5L round bottom flask, 78.2 g (481 mmol) of divinylbenzene (DVB) (80% by weight, technical grade), 29.4 g (300 mmol) of maleic anhydride (MA) and 2.15 g (8.88 mg mol) of benzoyl peroxide (BPO) was dissolved in 2153 g of ethyl acetate (EtOAc). The polymerizable composition had a percent solids of 4.9% by weight in EtOAc and contained a monomer mixture (58.1% by weight DVB, 27.3% by weight MA, and 14.5% by weight styrenic monomers) and 2% by weight BPO (based on monomer total weight). Nitrogen was bubbled through the polymerizable composition for 30 minutes. The flask was then capped with a rubber septum and placed in a 95°C sand bath. The polymerizable composition was heated at this elevated temperature for 18 hours. The white precipitate formed was isolated by vacuum filtration and washed with EtOAc. The solids were dispensed and placed into three 32 oz. jars. Each jar was then filled with 750 mL of EtOAc. The solid was allowed to stand in EtOAc for 1 h at ro...

Embodiment 3

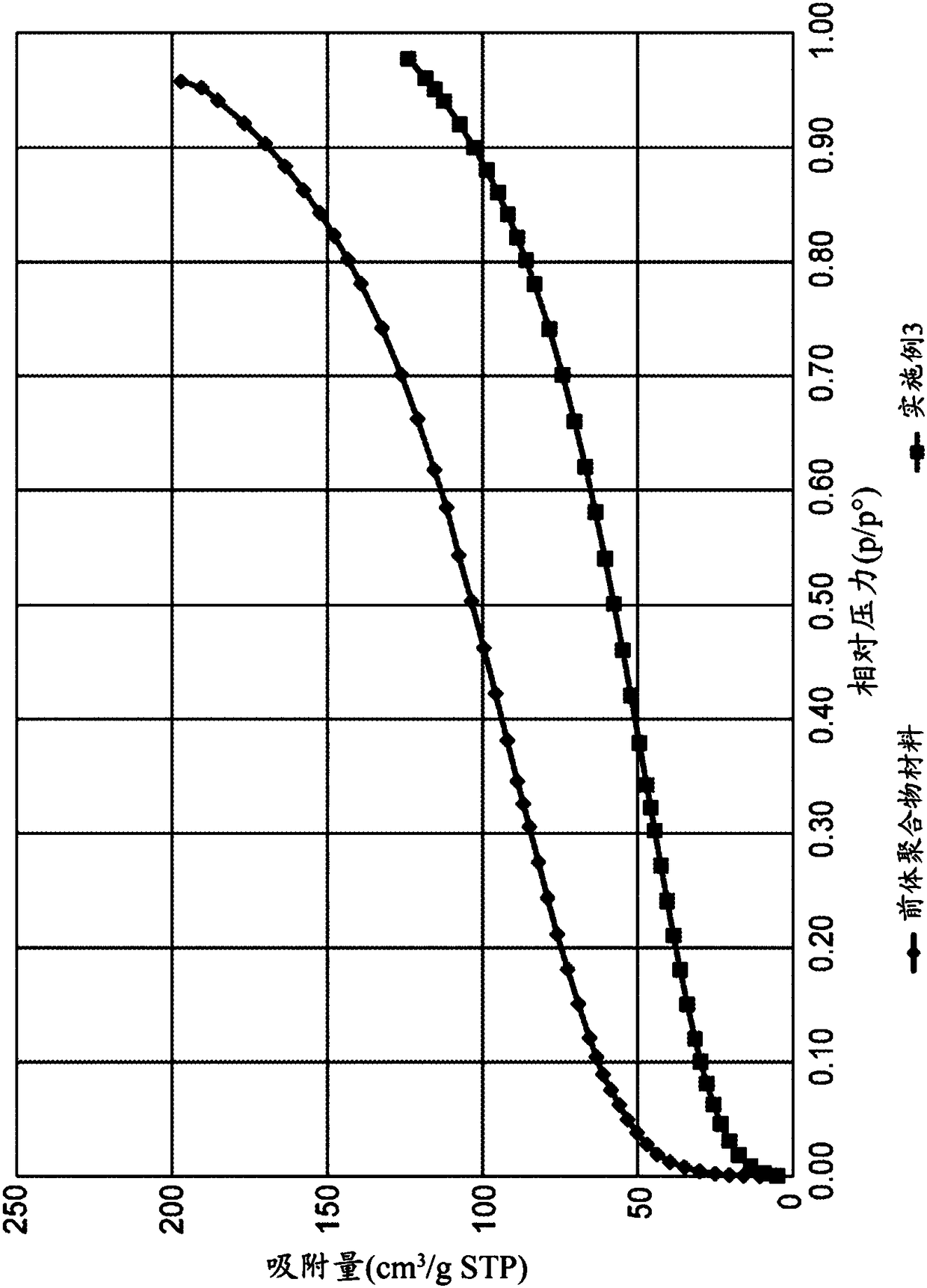

[0379] 3.99 g (24.5 mmol) DVB (80 wt%, technical grade), 6.01 g (61.3 mmol) MA and 204 mg (843 micromol) BPO were dissolved in 9.96 g EtOAc in a 4 oz jar. The polymerizable composition had a percent solids of 50.1% by weight in EtOAc and contained a monomer mixture (31.9% by weight DVB, 60.1% by weight MA, and 8.0% by weight styrenic monomers) and 2% by weight BPO (monomer based total weight). Nitrogen was bubbled through the polymerizable composition for 10 minutes. The jar was then capped and placed in a 95°C sand bath. The polymerizable composition was heated at this elevated temperature for 18 hours. The white precipitate formed was isolated by vacuum filtration and washed with EtOAc. The solid was placed in a 4 oz jar and 100 mL of EtOAc was added to the jar. The solid was allowed to stand in EtOAc at room temperature for 1 hour. The solid was isolated again by vacuum filtration and washed with EtOAc. The solid was placed in a 4 oz jar and 100 mL of EtOAc was added....

Embodiment 4-6

[0385] In a 2L Parr stainless steel pressure vessel, 177.11 grams (1.09 moles) of DVB (80 wt%, technical grade), 240.05 grams (2.45 moles) of MA, and 4.17 grams (16.8 mmoles) of VAZO52 were dissolved in 625.92 grams EtOAc. The polymerizable composition had a percent solids of 40.0% by weight in EtOAc and contained a monomer mixture (34.0% by weight DVB, 57.5% by weight MA, and 8.5% by weight styrenic monomers) and 1% by weight VAZO 52 (based on monomer total weight). Nitrogen was bubbled through the polymerizable composition for 15 minutes. The pressure vessel was then sealed and placed in a 60°C heating mantle. The polymerizable composition was heated at this elevated temperature for 18 hours. The white precipitate formed was isolated by vacuum filtration and washed with EtOAc. The solid was placed in a 4 L Erlenmeyer flask, and 2.0 L of EtOAc was added to the flask. The solid was allowed to stand in EtOAc at room temperature for 1 hour. The solid was isolated again by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com