Paper machine rewinding slitting device and dust removal system thereof

A technology of slitting device and dust removal system, which is used in metal processing and other directions to achieve stable operation, reduce the consumption of slitting knives, and reduce the problem of whitening in printing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

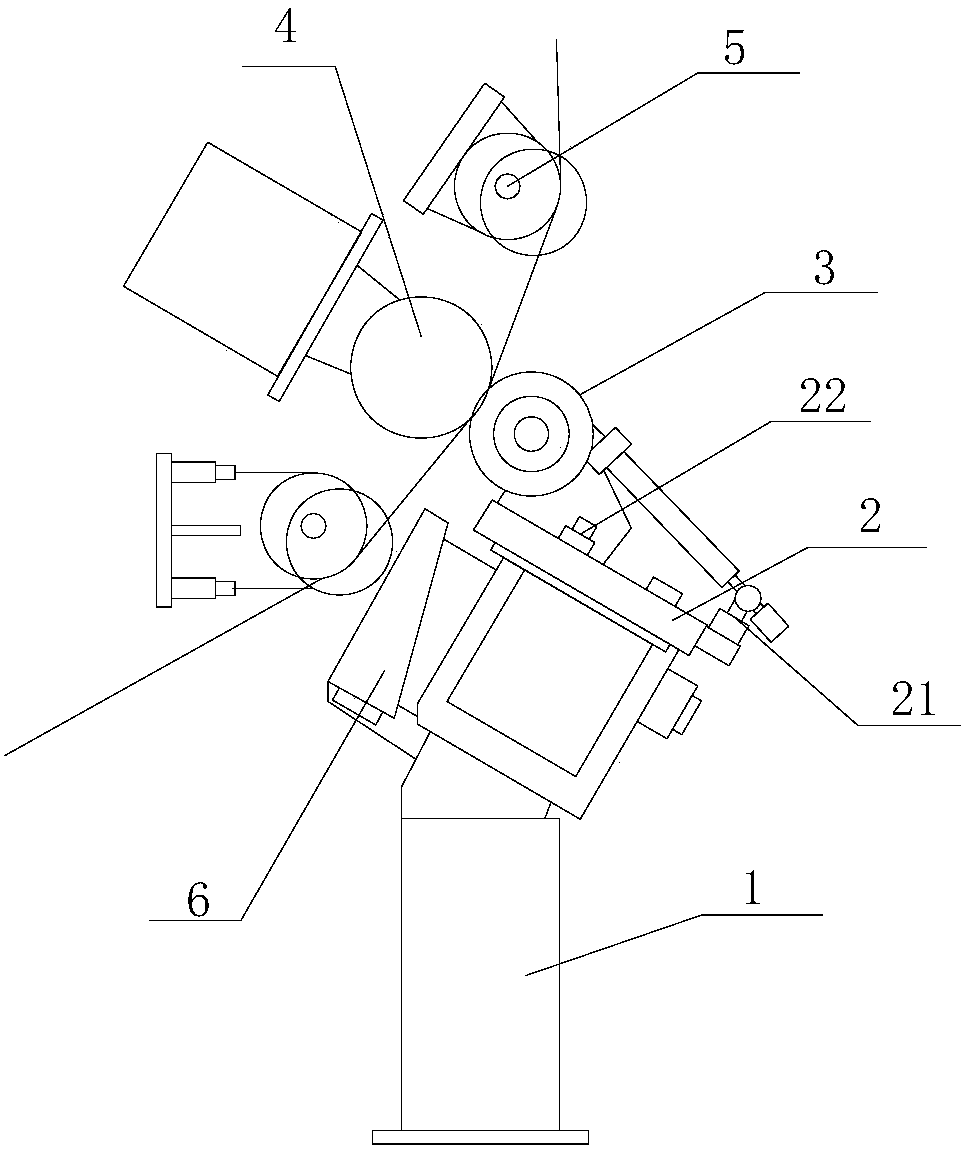

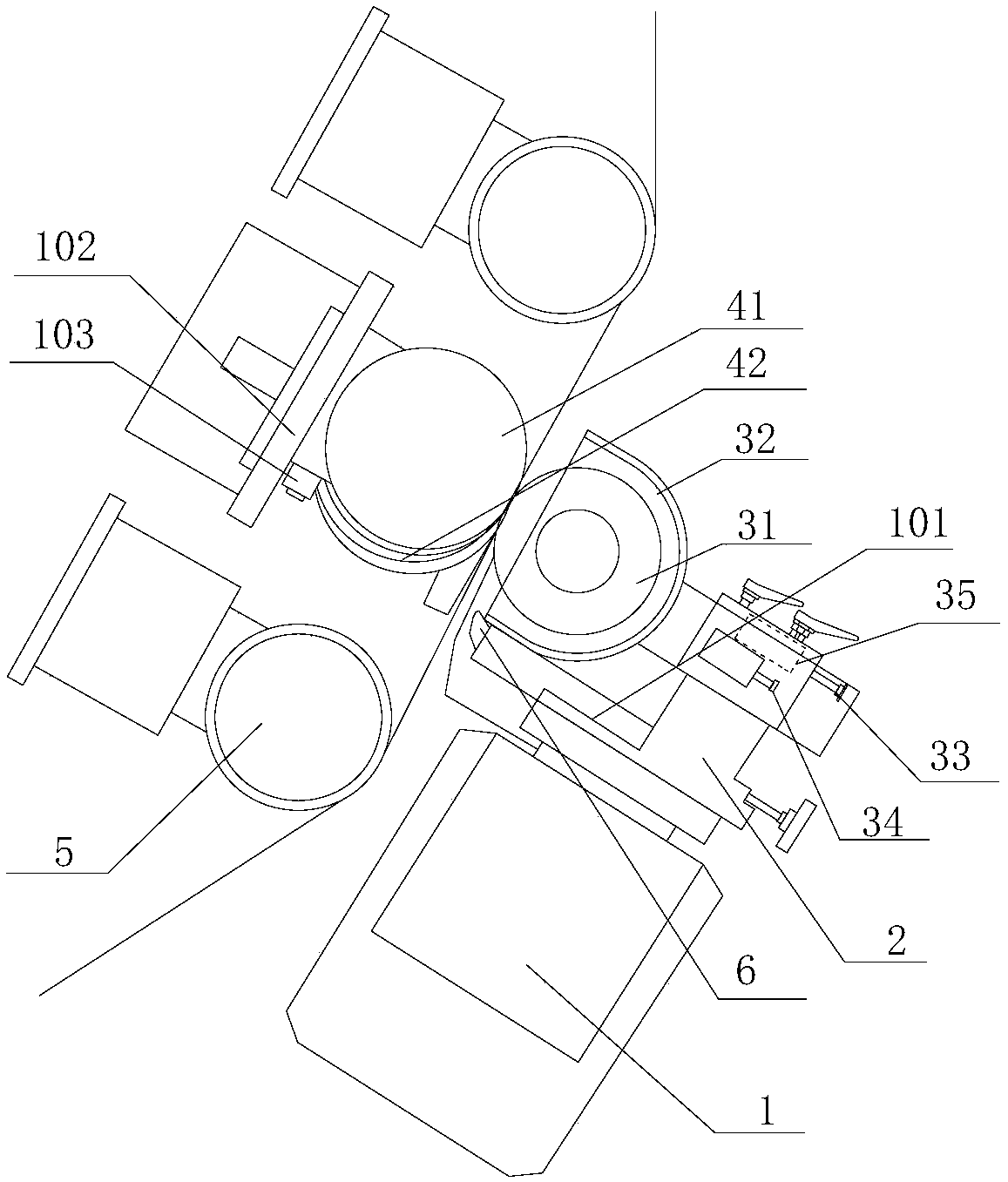

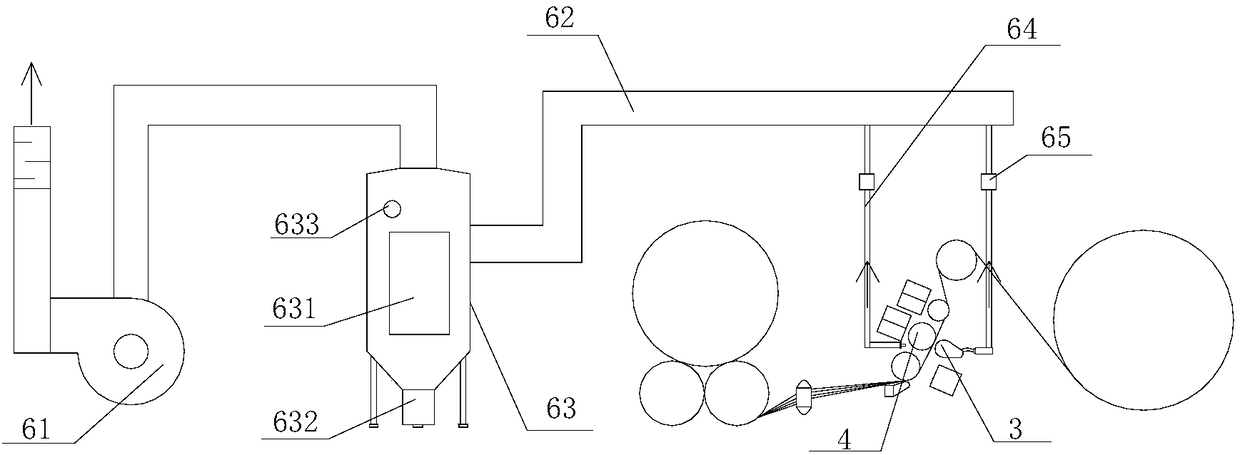

Embodiment 1

[0024] Slitting the coated paper, the coated paper is wound into a coated paper master roll, the roll weight is about 50 tons, the width of the banner is 6600mm, and the width of the banner is 790mm, 790mm, 890mm, 890mm, 890mm , 1200mm, 1150mm and other small paper rolls with seven banner widths. When the rewinding slitting and dust removal system of the present invention is used for slitting, 8 pairs of slitting knives are used. After the 8 top knife devices and 8 bottom knife devices move on their respective guide rails, the positioning device according to the cut paper rolls For banner width, the top knife device and the bottom knife device are positioned on the guide rail at a distance of 790mm, 790mm, 890mm, 890mm, 890mm, 1200mm, and 1150mm. The web is introduced into the slitting device system of the present invention from the parent roll of the paper roll through the guide roller. The wide paper web passes between the top knife device and the bottom knife device and is ...

Embodiment 2

[0027]Slitting the kraft liner paper, the kraft liner paper is rolled into a kraft liner board mother roll roll, the roll weight is about 45 tons, and the banner width is 6650mm. It needs to be cut into banner widths of 1850mm, 1850mm, 1900mm, Small paper rolls with four banner widths such as 1050mm. When the rewinding slitting and dust removal system of the present invention is used for slitting, 5 pairs of slitting knives are used. After 5 top knife devices and 5 bottom knife devices move on their respective guide rails, the positioning device according to the cut paper roll The top knife device and the bottom knife device are positioned on the guide rail at a distance of 1850mm, 1850mm, 1900mm, and 1050mm for the width of the banner. The top knife device and the bottom knife device are positioned on the guide rail in sequence and correspond to each other; Introduced into the slitting device system of the present invention through the guide roller, the wide paper web passes ...

Embodiment 3

[0030] The high-strength corrugated base paper is slit, and the high-strength corrugated base paper is rolled into a high-strength corrugated base paper master roll, with a roll weight of about 40 tons and a banner width of 5450mm. It needs to be cut into three banners with a banner width of 1850mm, 1400mm, and 2200mm. Width of small paper rolls. When the rewinding slitting and dust removal system of the present invention is used for slitting, 4 pairs of slitting knives are used. After the 4 top knife devices and 4 bottom knife devices move on their respective guide rails, the positioning device according to the cut paper roll The top knife device and the bottom knife device are positioned on the guide rail at a distance of 1850mm, 1400mm, and 2200mm for the width of the banner. The top knife device and the bottom knife device are positioned on the guide rail in turn and correspond to each other; The roll is introduced into the slitting device system of the present invention. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com