Composite honeycomb sandwich structure for oversized single-curved reflection surface and formation method thereof

A super-sized, honeycomb interlayer technology, applied in chemical instruments and methods, layered products, metal layered products, etc., to achieve the effect of improving the degree of mold sticking, reducing the amount of rebound, and high stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

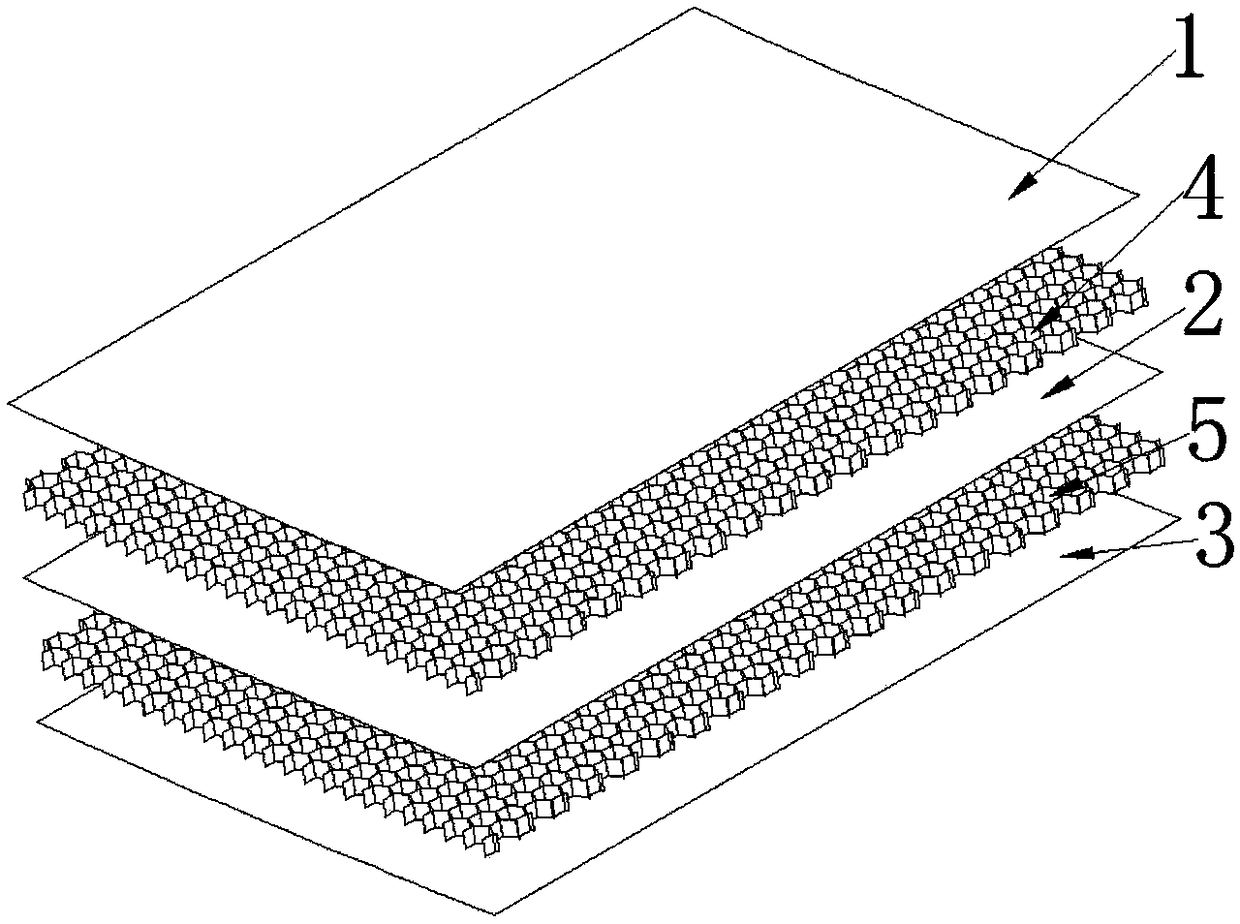

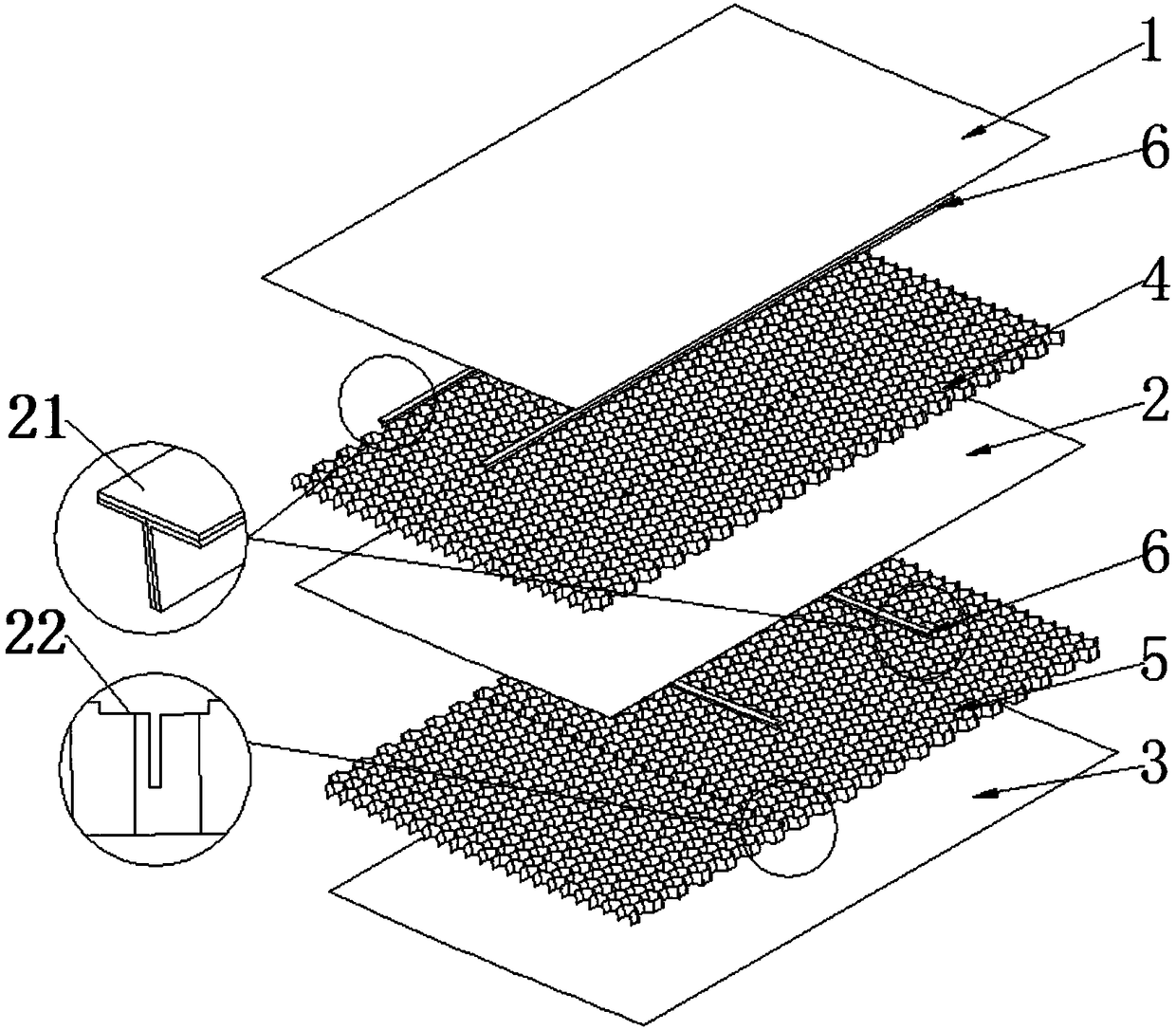

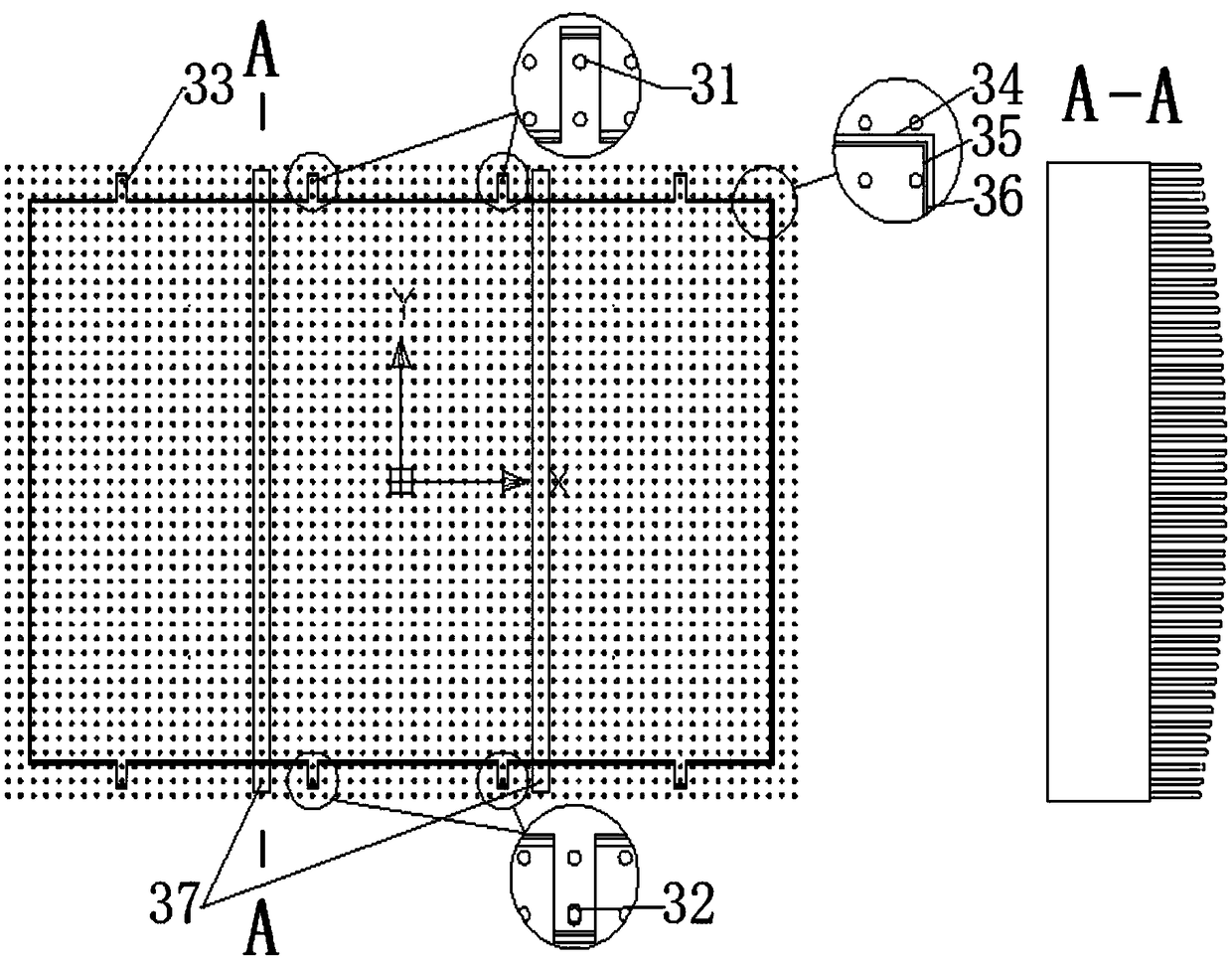

[0049] The present invention proposes a composite honeycomb sandwich structure for ultra-large-size high-precision single-curvature reflective panels. This composite honeycomb sandwich structure is composed of three layers of duralumin boards, two layers of honeycomb cores, and profile skeletons for connection and support. ; Wherein the three-layer duralumin board is the working board 1, the middle board 2 and the back board 3 respectively, and the two-layer honeycomb core is the honeycomb core 4 between the working board and the middle board and the honeycomb core between the middle board and the back board 5. The profile skeleton 6 added between the honeycomb sandwich core 5 and the back panel 3.

[0050] The present invention is a composite honeycomb interlayer structure of ultra-large-sized high-precision single-curvature reflective panels. Unfolding of a panel, calculation of nail height, positioning of three-layer duralumin board and profile skeleton on lattice nailing m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com