Gas washing method for laundry treatment equipment and laundry treatment equipment

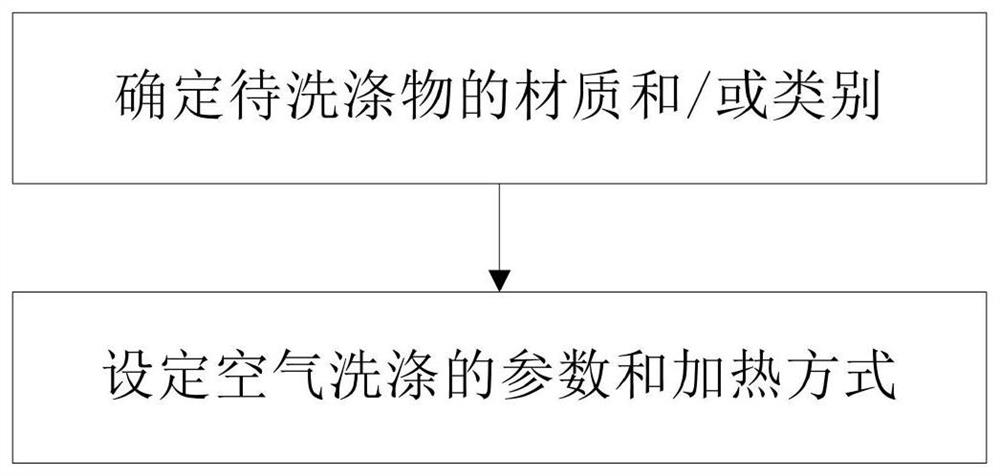

A clothing treatment device and a technology for gas washing, which are applied in the field of clothing treatment, can solve problems such as the inability to meet the cleaning requirements of medium and high-grade materials, and achieve the effects of being beneficial to gas washing, increasing elasticity, and improving elasticity and softness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The material to be washed is cashmere / silk scarf; the steps of "setting the parameters and heating method of air washing" include: setting the washing time to 5 minutes, the washing temperature to 40-50°C, the speed to 45rpm, and the spin-to-stop ratio to 30 / 5, the heating method is full heating. Because the material of cashmere is easy to be damaged, and silk scarves are generally thin and easy to be damaged, it is necessary to air wash the cashmere / silk scarf with the inner cylinder at a lower speed and rotation-stop ratio, and the washing time should be set The temperature should be set shorter, and the temperature should be set slightly lower. After repeated tests, observations, analyzes and comparisons by the inventor, setting the parameters to the above values can make the air washing effect of cashmere / silk scarves the best, and in the process of air washing Among them, the whole process of heating (that is, the heating air is always injected into the inner cy...

Embodiment 2

[0033] The material to be washed is wool / fur; the steps of "setting the parameters and heating method of air washing" include: setting the washing time to 7 minutes, the washing temperature to 50-60°C, the rotational speed to 45rpm, and the spin-to-stop ratio to 50 / 5. The heating method is to heat to 55°C first and then cool down naturally. Because the material of wool / fur is slightly more resistant to damage than cashmere and is not easy to wash, the washing time, washing temperature and the rotation-stop ratio of the inner cylinder can be appropriately increased to ensure that the wool / fur material to be washed is clean. It can be washed clean. After repeated tests, observations, analyzes and comparisons by the inventor, setting the parameters to the above values can make the air washing effect of wool / fur the best, and in the process of air washing, the heating method is first heating To 55 ℃ and then naturally cool down (even if the air in the inner tube is naturally co...

Embodiment 3

[0035] The material to be washed is pure leather / imitation leather; the steps of "setting the parameters and heating method of air washing" include: setting the washing time to 9 minutes, the washing temperature to 50-60°C, the rotational speed to 70rpm, and the spin-to-stop ratio to 55 / 5, the heating method is to heat to 55°C first and then cool down naturally. Since the pure leather / imitation leather material is more resistant to damage and less easy to wash than the wool / fur material, the washing time, the speed of the inner cylinder and the turn-to-stop ratio can be further increased to ensure that the pure leather / imitation leather The leather material to be washed can be cleaned. After repeated tests, observations, analyzes and comparisons by the inventor, setting the parameters to the above values can make the air washing effect of pure leather / imitation leather the best, and the air washing effect of air washing can be the best. During the process, in order to avoid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com