Positioning marker made of degradable metal and method for preparing positioning marker

A technology for positioning markers and markers, applied in the direction of diagnostic markers, echo/ultrasonic imaging agents, X-ray contrast agent preparation, etc., can solve the problems of patients with foreign body sensation and moving to other parts, so that it is not easy to fall off or shift, and it is not easy to Displacement, biocompatibility enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

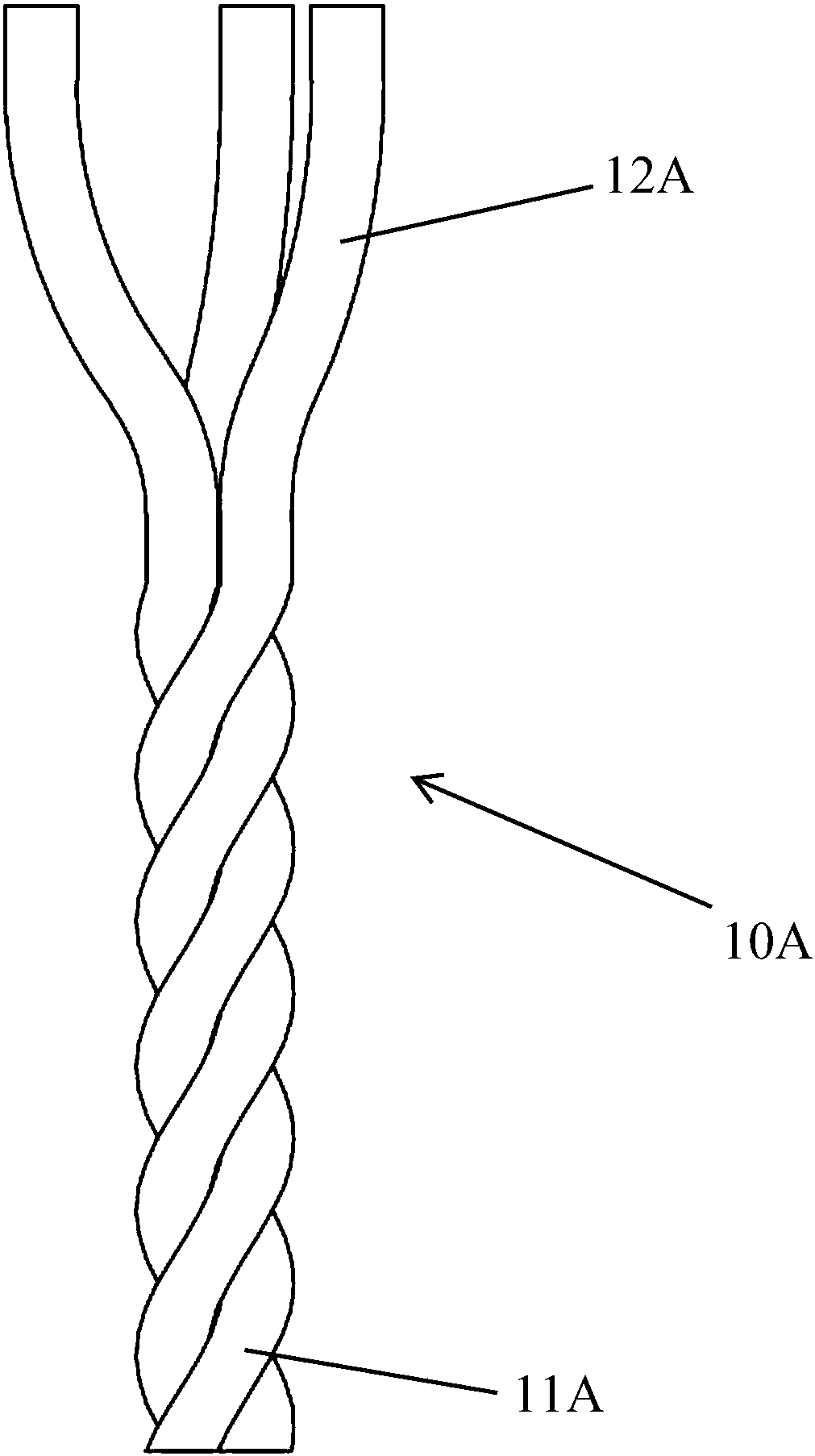

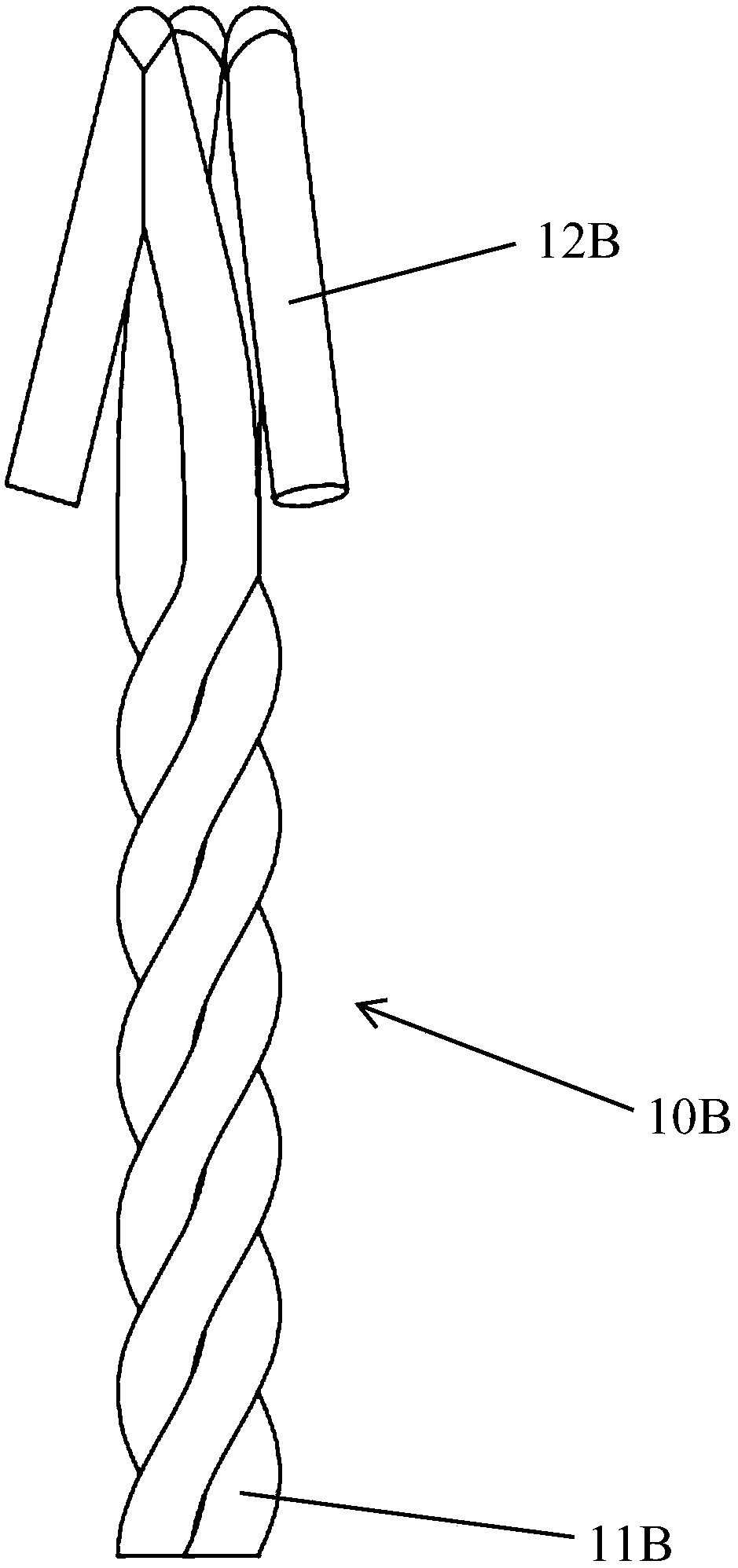

[0027] In order to be able to understand the technical features and practical effects of the present invention in detail, and to implement them according to the contents of the description, the preferred embodiment as shown in the accompanying drawings is further described in detail as follows, please refer to the first preferred embodiment. figure 1 The illustrated positioning marker made of degradable metal includes a marker body 10A.

[0028] The length of the marker body 10A is 10-20 mm, and the diameter of the outermost edge is 1-3 mm. The marker body 10A is a long strip structure made of at least three magnesium wires made of pure magnesium wire or magnesium alloy. , preferably, the diameter of each magnesium wire is 0.5 mm to 0.8 mm.

[0029] One end of the marker body 10A forms a winding end 11A that is intertwined with each other, and the winding end 11A can be in contact with a push rod in a puncture needle sleeve, and a positioning end that is separated from each ot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com