Station instrument for placing trunk lids

A technology for work station appliances and trunk lids, which is applied to manufacturing tools, tool storage devices, workshop equipment, etc., can solve the problem that the trunk lids of automobiles cannot be placed in accordance with uniform standards, increase the labor intensity and working hours of operators, and cannot adapt to automobiles. Large-scale production line and other problems, to achieve the effect of easy maintenance and replacement, reduced labor intensity and working hours, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention will be further described:

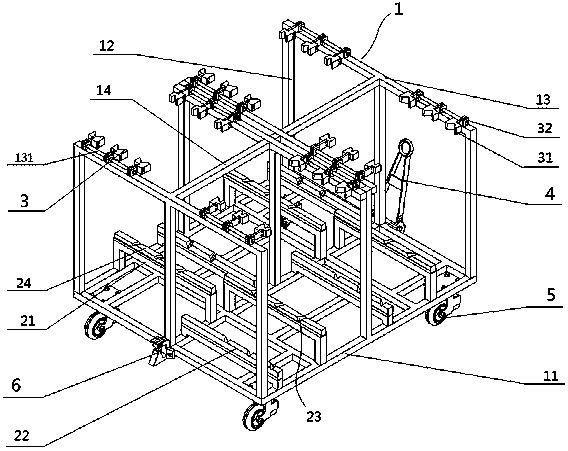

[0029] figure 1 An embodiment of a station appliance for placing a trunk lid according to the present invention is shown. figure 1 It is a structural schematic diagram of the station equipment for placing the trunk lid in this embodiment.

[0030] like figure 1 As shown, the main body of the station equipment for placing the trunk lid in this embodiment is a frame structure 1, and a plurality of uprights 12 are arranged in a rectangular array on the bottom frame 11 of the frame structure 1, and the upper ends of the uprights 12 pass through the corresponding Corresponding crossbars 13 and longitudinal beams 14 are connected to form one or more accommodating spaces, and protective limiting devices are arranged in the accommodating spaces, so as to facilitate the vertical stacking of the trunk lids. In this embodiment, there are four accommodation spaces. In this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com