Preparation technology of caprolactam composite sodium salt

A technology for the preparation of caprolactam, which is applied in the field of preparation of caprolactam composite sodium salt, can solve the problems of easy moisture absorption and deterioration, unsuitable for long-term preparation of large-sized products, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Take 10kg of solid caprolactam, heat it up to 100°C in a sealed 50-liter stainless steel tank and melt it for 2 hours, then vacuumize and remove water for 30 minutes until the liquid level is calm, and keep the vacuum at 1000pa;

[0019] Add 333g of powdered NaOH and stir evenly, then slowly raise the temperature to 130°C and continue vacuuming to below 100pa until the water is completely removed and the liquid level is calm;

[0020] Slowly cool down the obtained mixture to 70°C, add 100 g of hexahydro-2H-azepine-2-one, and stir slowly while adding;

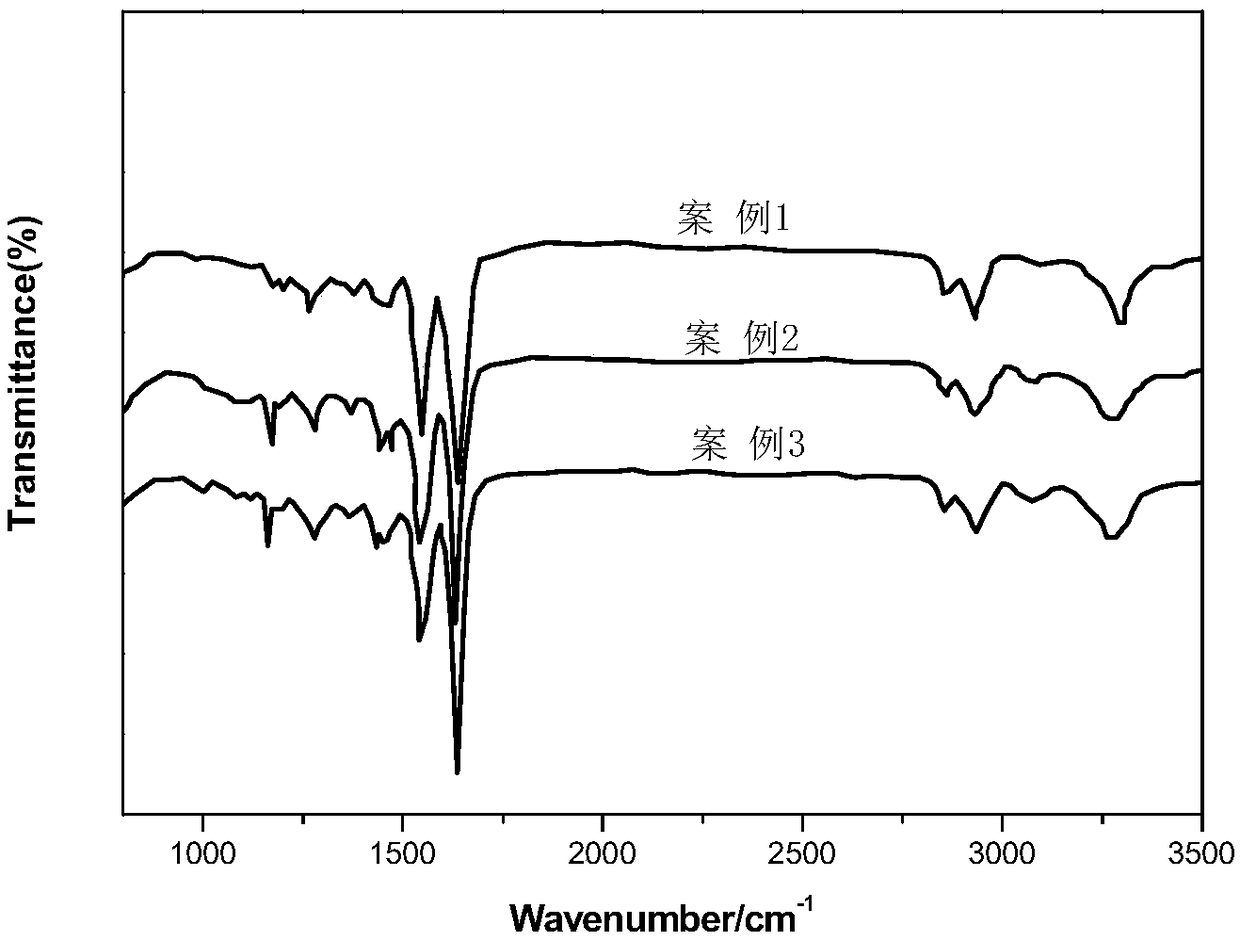

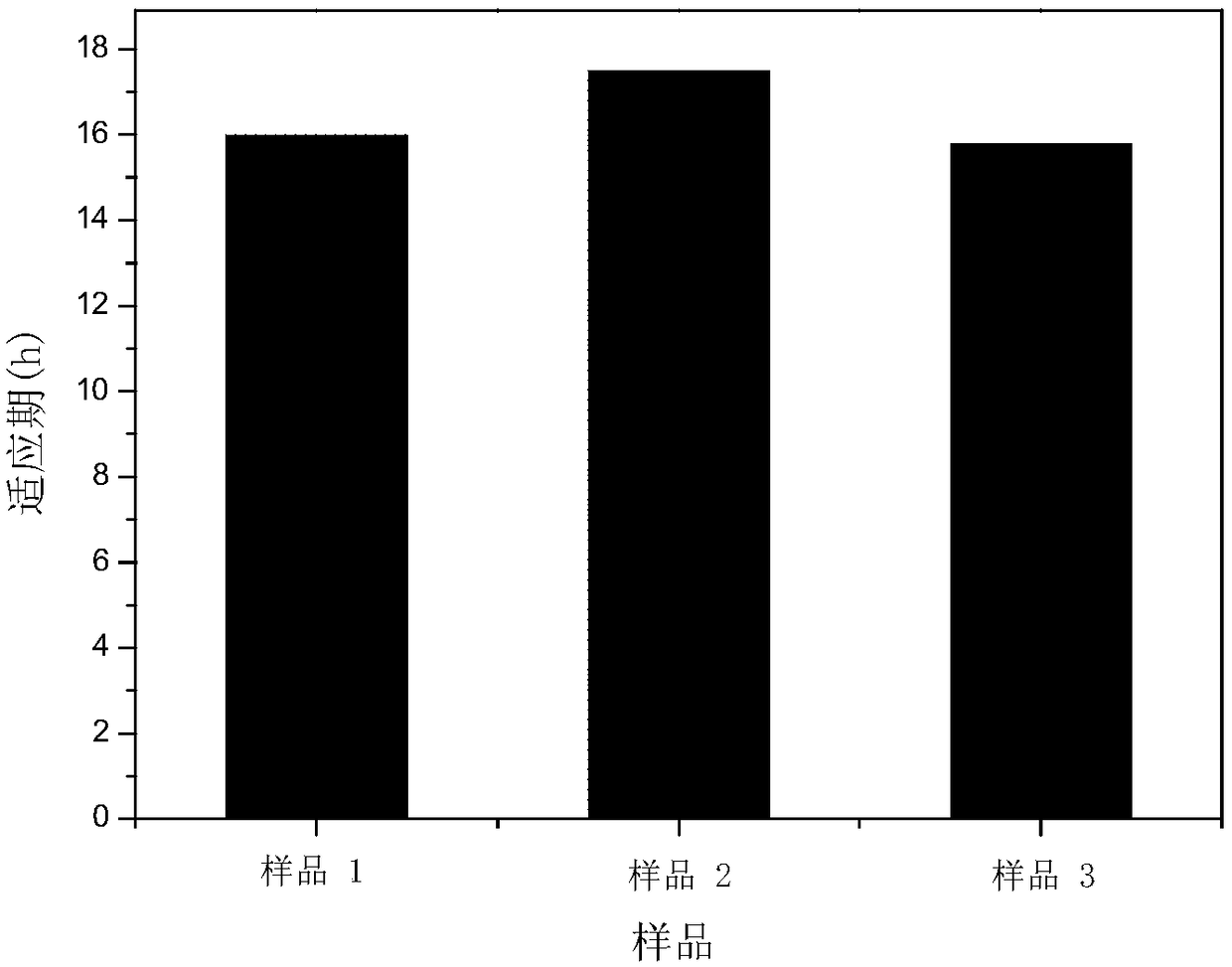

[0021] The mixed solution obtained by stirring evenly was cooled to 40°C at a cooling rate of 5°C / min, then removed from the reactor, slowly cooled to room temperature, sealed and isolated from the air, and condensed to a white solid at 25°C, which was the lactam complex sodium salt. After casting experiments, it was found that the product has the characteristics of good stability and long adaptation period (attached fig...

Embodiment 2

[0023] Take 5kg of solid caprolactam, heat it up to 100°C in a sealed 50-liter stainless steel tank and melt it for 2 hours, vacuumize and remove water for 30 minutes until the liquid level is calm, and keep the vacuum at 720pa;

[0024] Add 100g of powdered NaOH and stir evenly, then slowly heat up to 130°C and continue vacuuming to below 100pa until the water is completely removed and the liquid level is calm;

[0025] Slowly cool down the obtained mixture to 70°C, add 50 g of hexahydro-2H-azepine-2-one, and stir slowly while adding;

[0026] The mixed solution obtained by stirring evenly was cooled to 40°C at a cooling rate of 3°C / min, then removed from the reactor, slowly cooled to room temperature, sealed and isolated from the air, and condensed to a white solid at 25°C, which was the lactam complex sodium salt. After casting experiments, it was found that the product has the characteristics of good stability and long adaptation period (attached figure 1 Infrared test an...

Embodiment 3

[0028] Take 15kg of solid caprolactam, heat it up to 100°C in a sealed 50-liter stainless steel tank and melt it for 2 hours, vacuumize and remove water for 30 minutes until the liquid level is calm, and keep the vacuum at 1000pa;

[0029] Add 500g of powdered NaOH and stir evenly, then slowly heat up to 130°C and continue vacuuming to below 100pa until the water is completely removed and the liquid level is calm;

[0030] Slowly cool down the obtained mixture to 70°C, add 75g of hexahydro-2H-azepine-2-one, and stir slowly while adding;

[0031] The mixed solution obtained by stirring evenly was cooled to 40°C at a cooling rate of 2°C / min, then removed from the reactor, slowly cooled to room temperature, sealed and isolated from the air, and condensed to a white solid at 25°C, which was the lactam complex sodium salt. After casting experiments, it was found that the product has the characteristics of good stability and long adaptation period (attached figure 1 Infrared test a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com