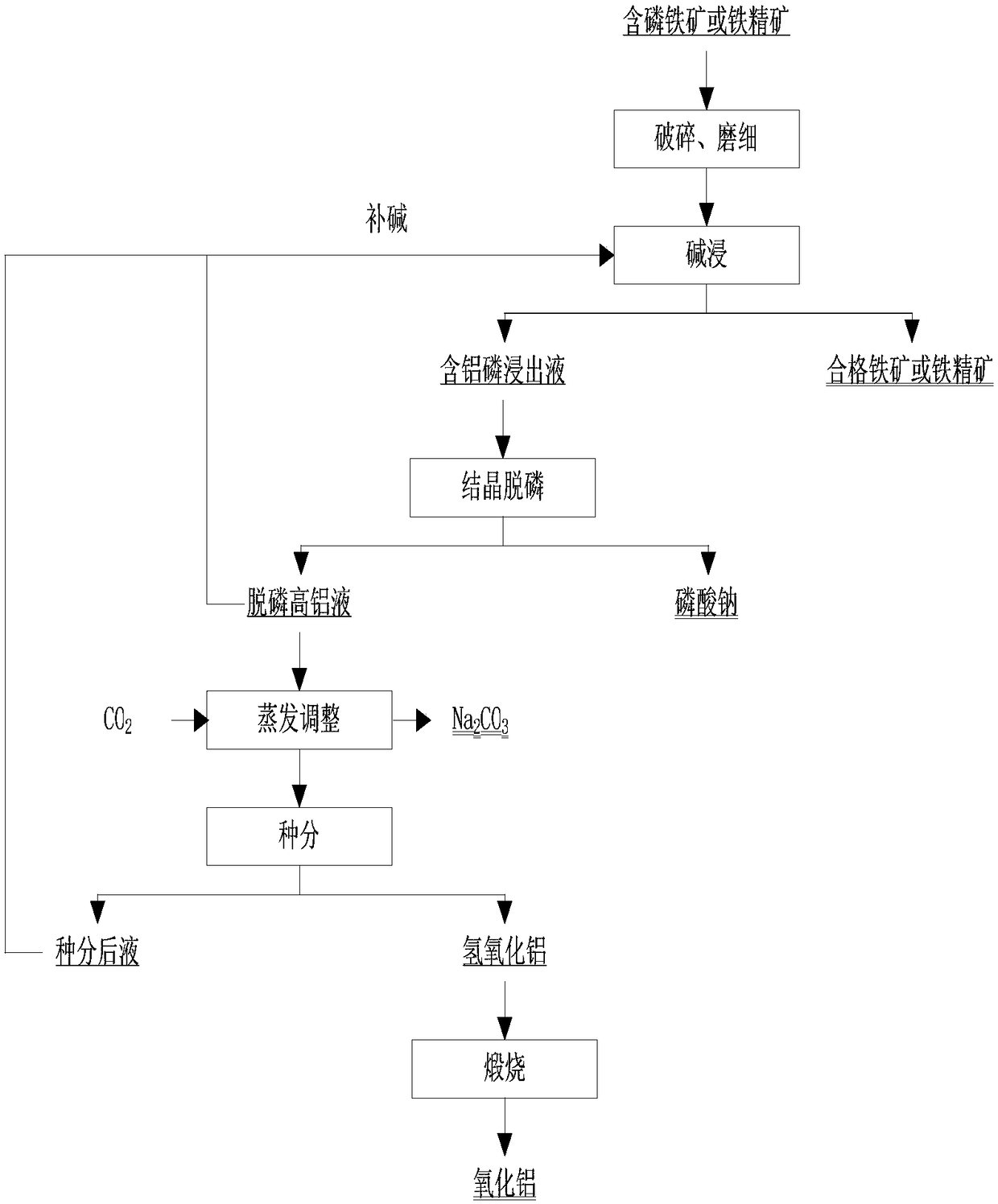

Method for alkali leaching dephosphorization of phosphorus-containing iron ore

A technology for iron ore alkali and iron ore, which is applied to phosphorus by-products, realizes the recycling of alkali liquor, can solve the problems affecting the low cost and high value utilization of phosphorus-containing iron ore, and achieves the effect of high iron recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Mix the iron concentrate with 100g / L NaOH solution for leaching, the leaching liquid-solid ratio is 5:1, the temperature is 90°C, and the time is 2h. After solid-liquid separation, the leaching rate of aluminum is 85%, and the leaching rate of phosphorus is 80%.

Embodiment 2

[0039] Mix the iron concentrate with 200g / L NaOH solution for leaching, the leaching liquid-solid ratio is 6:1, the temperature is 95°C, and the time is 3h. After solid-liquid separation, the leaching rate of aluminum is 92% and the leaching rate of phosphorus is 85%.

Embodiment 3

[0041] Mix the iron concentrate with 100g / L NaOH solution for leaching, the leaching liquid-solid ratio is 8:1, the temperature is 50°C, and the time is 2h. After solid-liquid separation, the aluminum leaching rate is 72% and the phosphorus leaching rate is 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com