Copper foil power source structure convenient to maintain

A technology of power supply and copper foil, applied in electroforming, electrolysis process, electrolysis components, etc., can solve the problems of space distribution and inconvenient maintenance and operation, and achieve the effect of compact structure, reduced consumption and reasonable power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

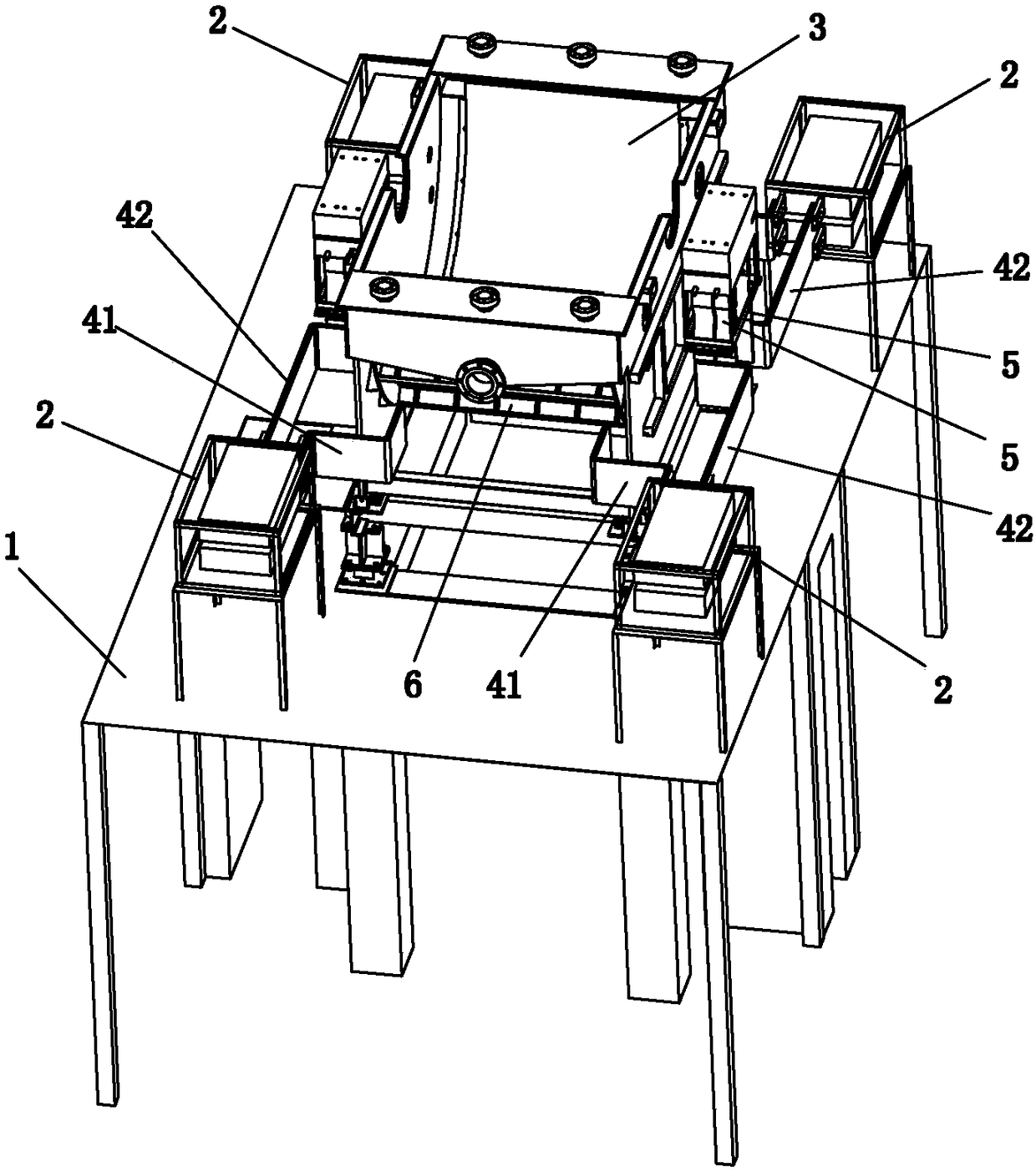

[0025] like figure 1 Shown is embodiment one ( figure 1 Cathode roller 7 is not shown in the drawing), the foil machine 3 is installed on the foil machine platform 1, the foil machine platform 1 is supported by the pillars below it, and the opposite sides of the foil machine 3 are provided for connecting with the cathode roller. 7 is connected to the electrical connection terminal 5, and the anode plate 6 is located on the other two opposite sides. The power structure includes four power modules 2 .

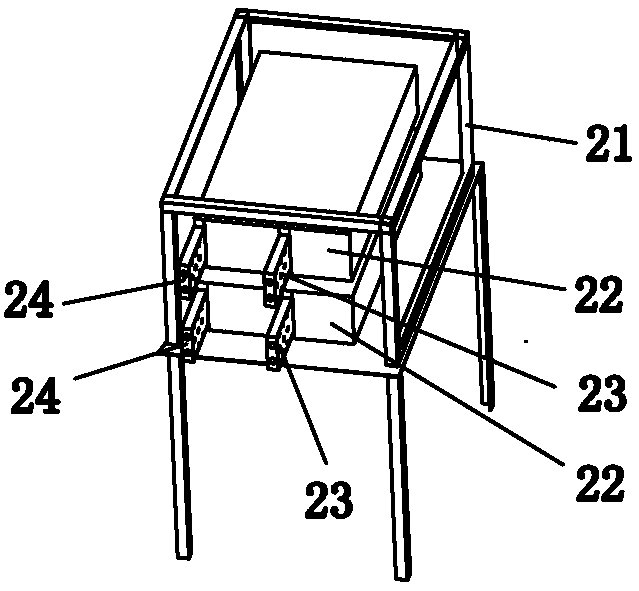

[0026] like figure 2 As shown, the power supply module 2 includes a bracket 21 and two power stand-alone units 22. The support 21 is a rectangular frame for encapsulating or supporting the power supply stand-alone unit. Stacked, the control terminal and core components of the power stand-alone unit 22 are located on the side facing the outside. The weight of the stand-alone power supply 22 is about tens of kilograms. In order to facilitate maintenance and installation, the s...

Embodiment 2

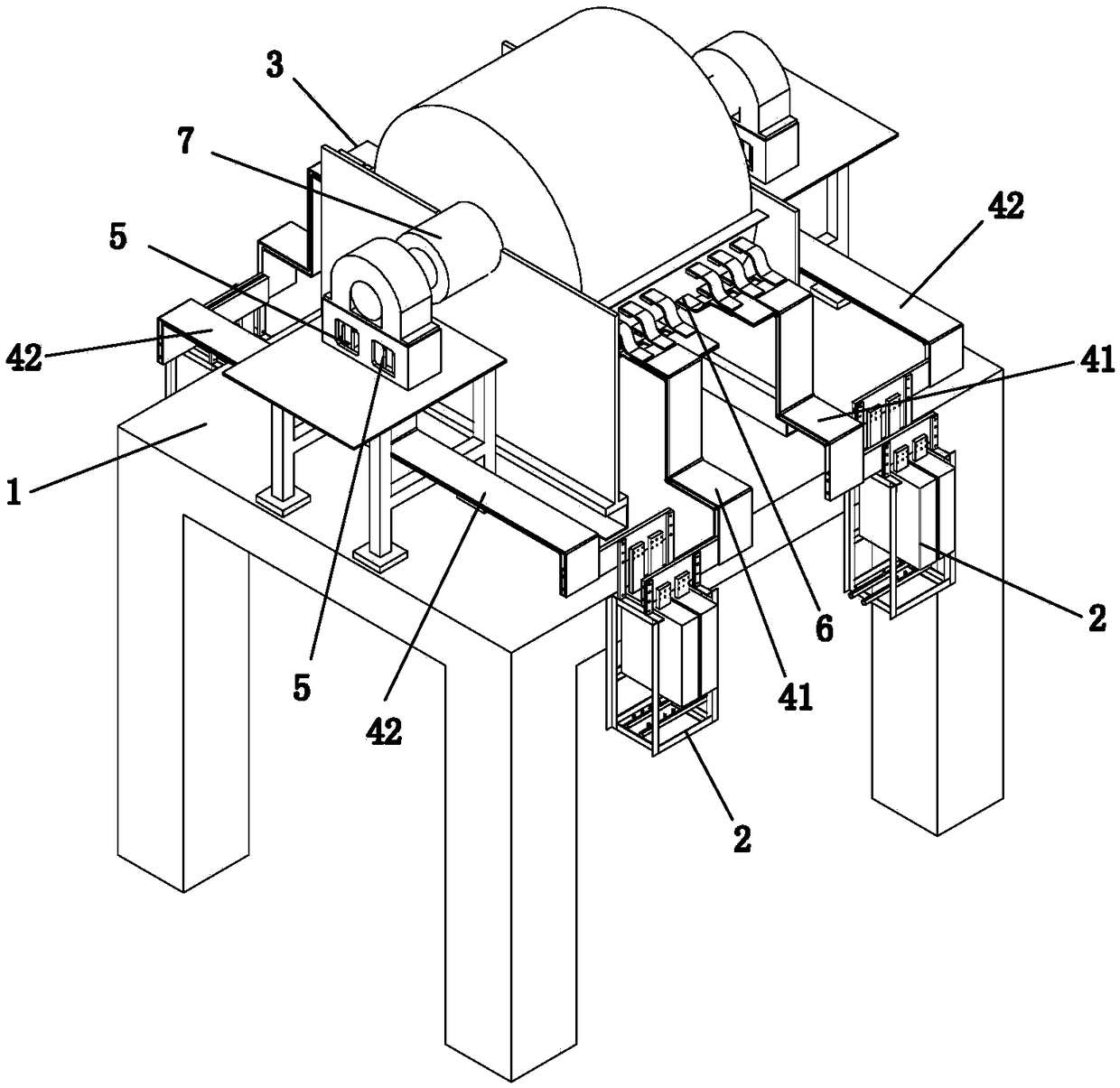

[0030] like image 3 Shown is the second embodiment, the foil machine 3 is also installed on the foil machine platform 1, and the foil machine platform 1 is supported by the pillars below it. The power supply structure also includes four power supply modules 2 .

[0031] like Figure 4 As shown, the power supply module 2 includes a bracket 21 and two power stand-alone units 22, the power stand-alone unit 22 is vertically installed in the support 21, and the two power supply unit 22 are distributed correspondingly on the left and right, and the control terminal and core components of the power unit 22 are located below. Both the positive pole 24 and the negative pole 23 of the stand-alone power supply 22 are located on the vertically upward side of the bracket 21, and the negative pole 23 is longer than the positive pole 24, so that the positive pole and the negative pole are staggered from each other, leaving enough maintenance space, so that the connection of the positive po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com