Tubular column for evenly injecting steam in SAGD (Steam Assisted Gravity Drainage) horizontal well and process

A steam injection pipe and steam injection technology, which is applied in wellbore/well components, wellbore/well valve devices, and production fluids, etc. It can improve the efficiency and uniformity of steam injection, shorten the preheating time, and achieve good economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

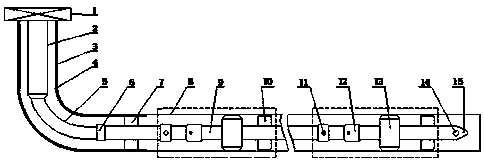

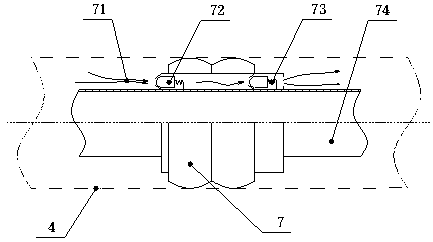

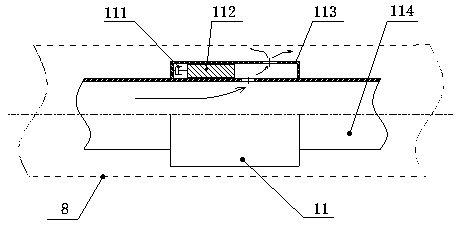

[0043] Such as figure 1 As shown, a SAGD horizontal and uniform steam injection column includes a vacuum heat insulation pipe 2, a thermal compensation telescopic pipe 5 and a steam injection pipe 9 in sequence, and the vacuum heat insulation pipe 2 and the steam injection pipe 9 pass through the thermal compensation telescopic pipe 5 connected, the front of the steam injection pipe 9 is provided with a backwash packer 7, and the backwash packer 7 is arranged outside the steam injection pipe 9, which isolates the upper part of the steam injection pipe 9 from the well completion casing 4 The annular space between; the middle part of the steam injection pipe 9 is provided with one or more fracturing-gas injection units, and the fracturing-gas injection unit includes a fracturin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com