Full-automatic silicon wafer turnover dryer

A dryer, fully automatic technology, applied in the direction of dryers, drying, non-progressive dryers, etc., can solve the problems of low intelligence and automation, waste of time, manpower and material resources, etc., to achieve improved drying Quality, reduce moisture residue, facilitate the effect of popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

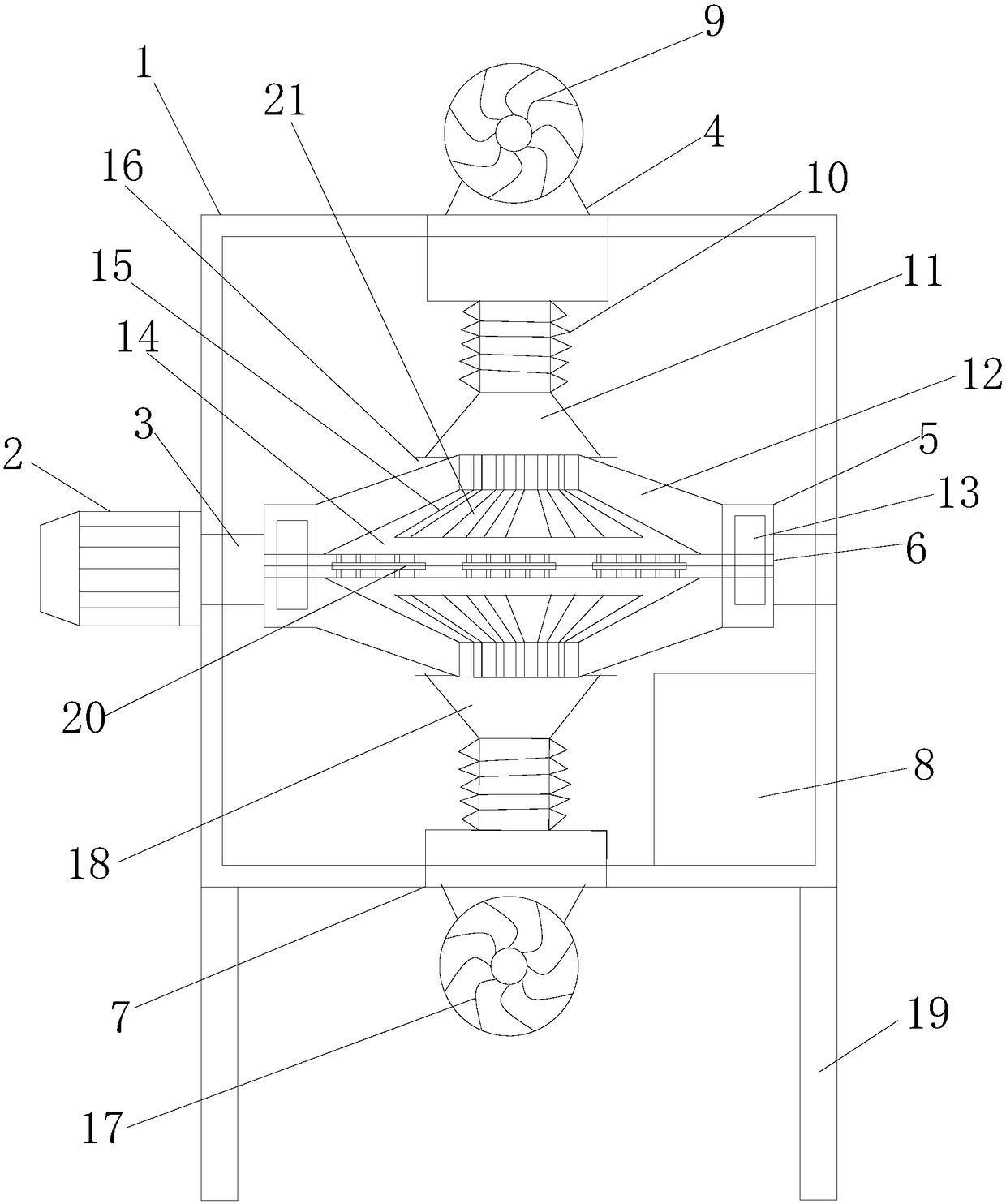

[0014] Refer to figure 1 , The present invention is a fully automatic silicon wafer turning-over drying machine, which includes a drying box 1, a rotating motor 2, a linkage shaft 3, a blower 4, a dryer 5, a silicon disk 6, an air extractor 7, and a control center 8. The blower 4 is set on the top of the drying box 1. The blower 4 includes a blower 9, an electric telescopic air pipe 10, and an air inlet cup 11, and the blower 9 is set on the top of the drying box 1. The electric telescopic air pipe 10 passes through the drying box 1 and is arranged vertically downwards in the drying box 1, the bottom end of the electric telescopic air pipe 10 is equipped with an air inlet cup 11, and the air blower 4 is provided with a drying The dryer 5 includes a turning plate 12, a heater 13, a drying cavity 14, a wind turntable 15, and a cup sealing induction ring 16. The left and right ends of the turning plate 12 are provided with heaters 13, so The drying cavity 14 is arranged in the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com