Multi-stage vibration dryer

A technology of vibrating drying and vibrating box, which is applied in the direction of drying machine, drying solid materials, heating to dry solid materials, etc. It can solve the problems affecting the quality of raw material molding, reduce moisture residue, enhance the effect of raw materials, and have a compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

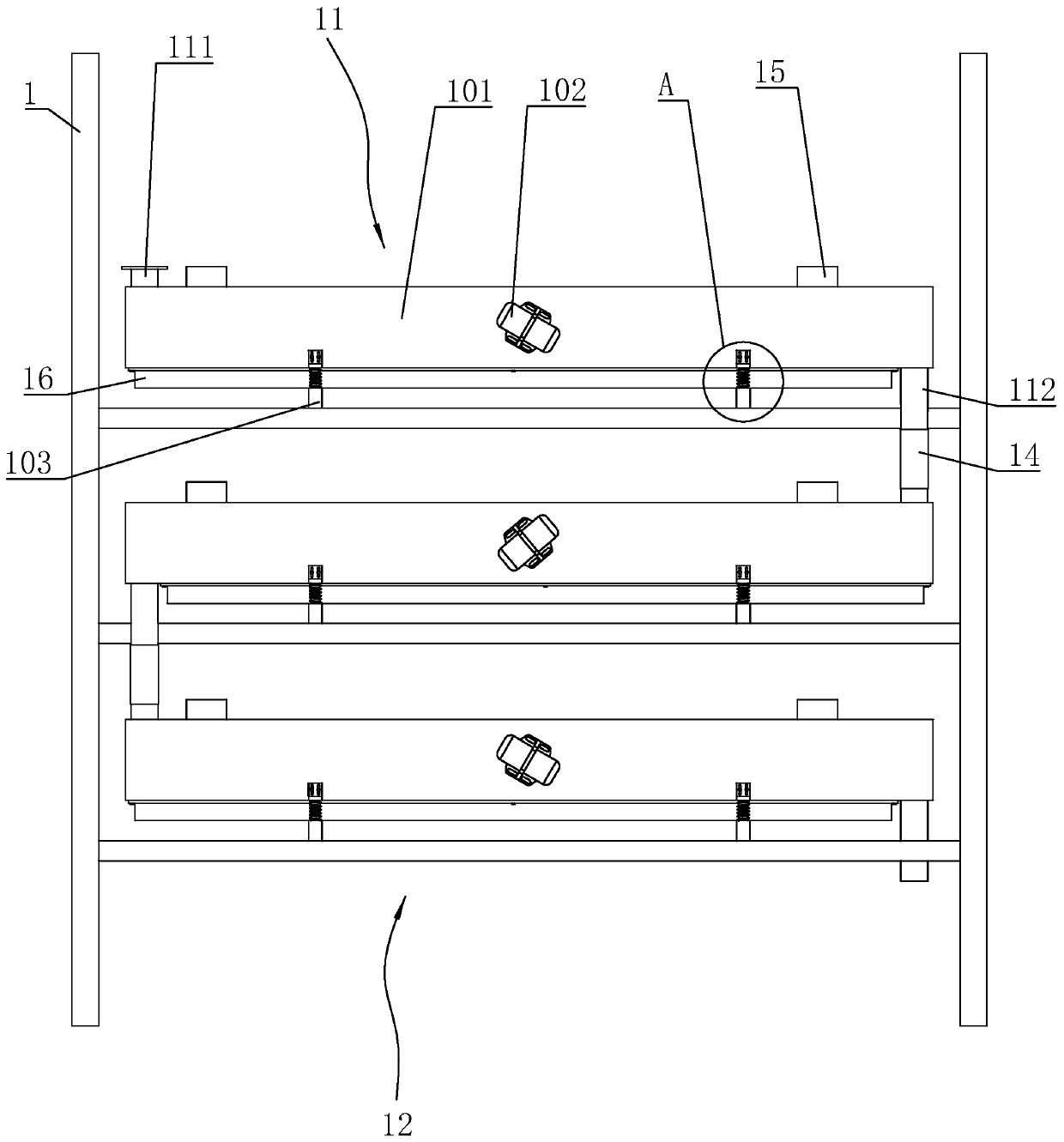

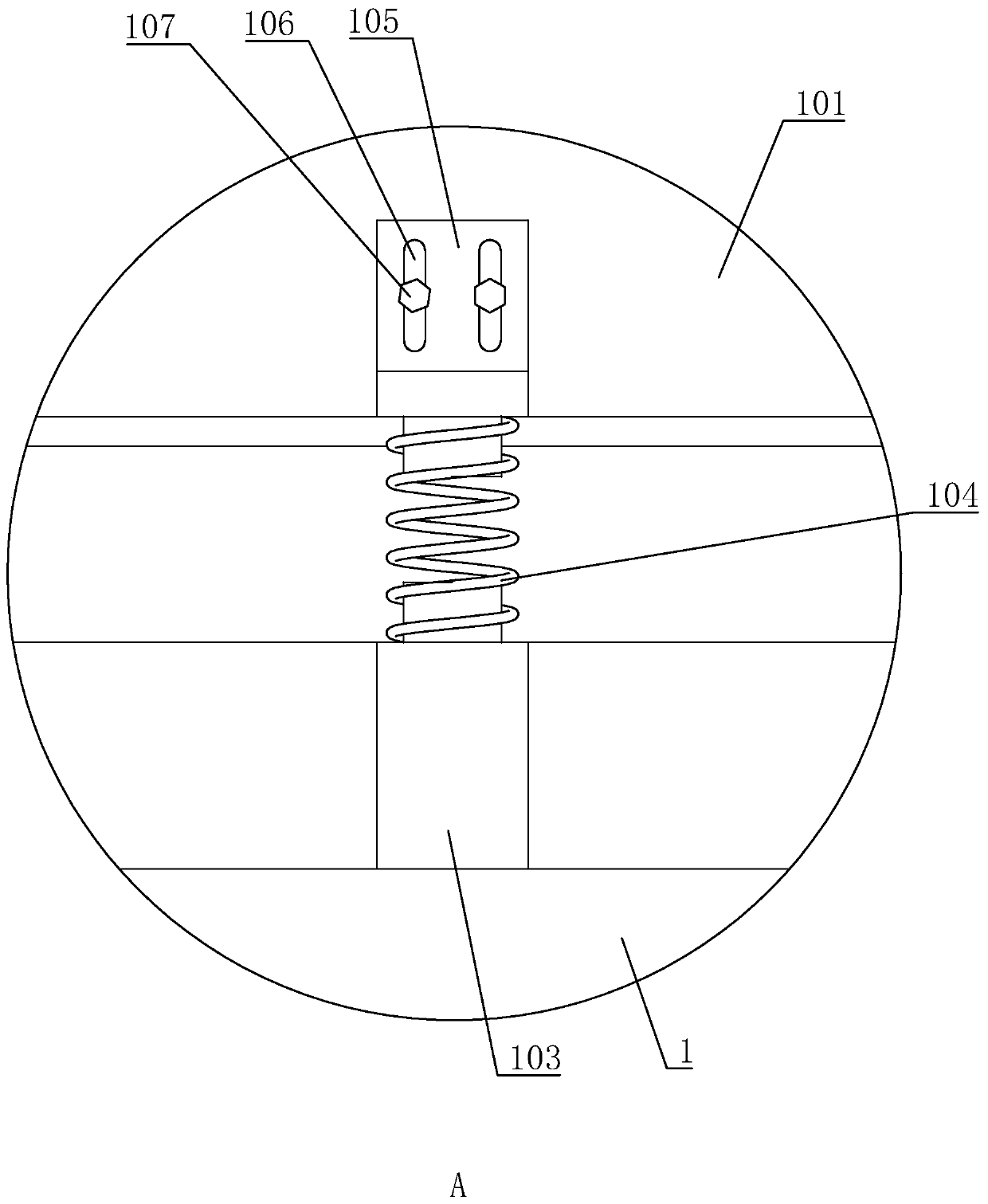

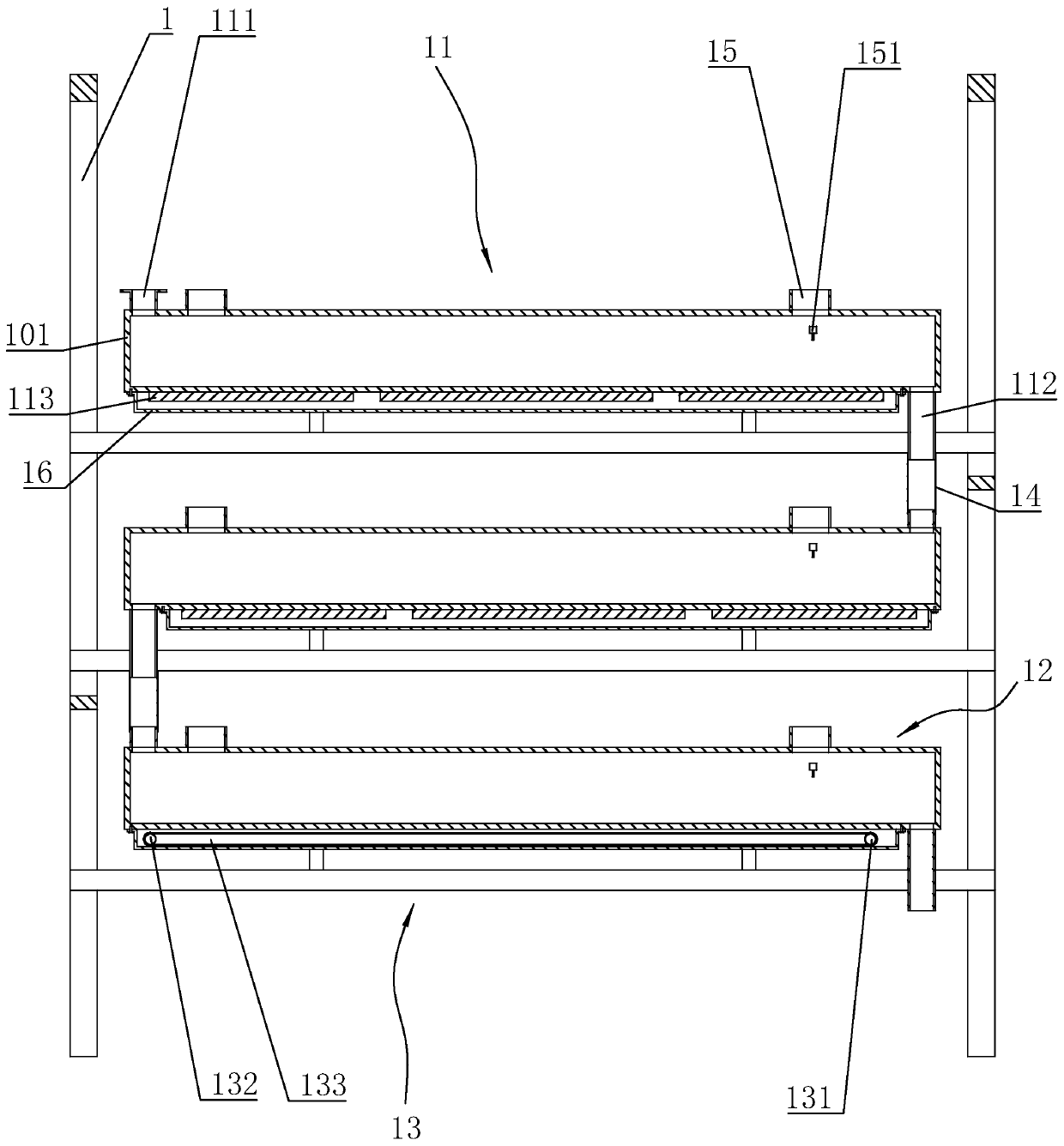

[0036] Embodiment one: if figure 1 and figure 2 As shown, it is a multi-stage vibrating dryer disclosed by the present invention, which includes a frame 1, and the frame 1 is provided with two vibrating drying boxes 11 and a vibrating cooling box 12 arranged vertically from top to bottom. The vibrating drying box 11 is elastically connected to the frame 1 and the bottoms of the two vibrating drying boxes 11 are provided with an electromagnetic heating element 113, the electromagnetic heating element 113 is an electromagnetic heater, and the upper part of one end of the vibrating drying box 11 is provided with a feed port 111 , the lower part of the other end is provided with a discharge port 112 .

[0037] Such as image 3 As shown, the vibrating cooling box 12 and the vibrating drying box 11 are vibrating boxes with the same structure, and the discharge ports 112 of two adjacent vibrating boxes are connected with the feeding port 111 by a flexible pipe 14, and each vibrati...

Embodiment 2

[0045] Embodiment two: a kind of multi-stage vibration dryer, such as Figure 5 As shown, the difference from Embodiment 1 is that the material box 101 adopts a seamless round tube, the top material box 101 is connected with an exhaust pipe 2, and the material box 101 corresponding to each vibration drying box 11 is provided with a seal. 21. The sealing member 21 includes several butterfly valves, and the butterfly valves are installed on the material inlet 111 and the material outlet 112 of the upper material box 101 and the material outlet 112 of the lower material box 101 .

[0046] Such as Figure 5 As shown, the three butterfly valves are divided into first, second, and third according to the order of raw material transmission. When drying, put the raw material into the first material box 101, the first and second butterfly valves are closed, and the third butterfly valve is opened. , connect the exhaust pipe 2 to the vacuum pump, seal the material intake port 15, when h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com