Mechanical performance testing system and method for carbon nanotube fibers in high-temperature state

A carbon nanotube fiber, high temperature technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, scientific instruments, etc., to achieve the effect of simple structure and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

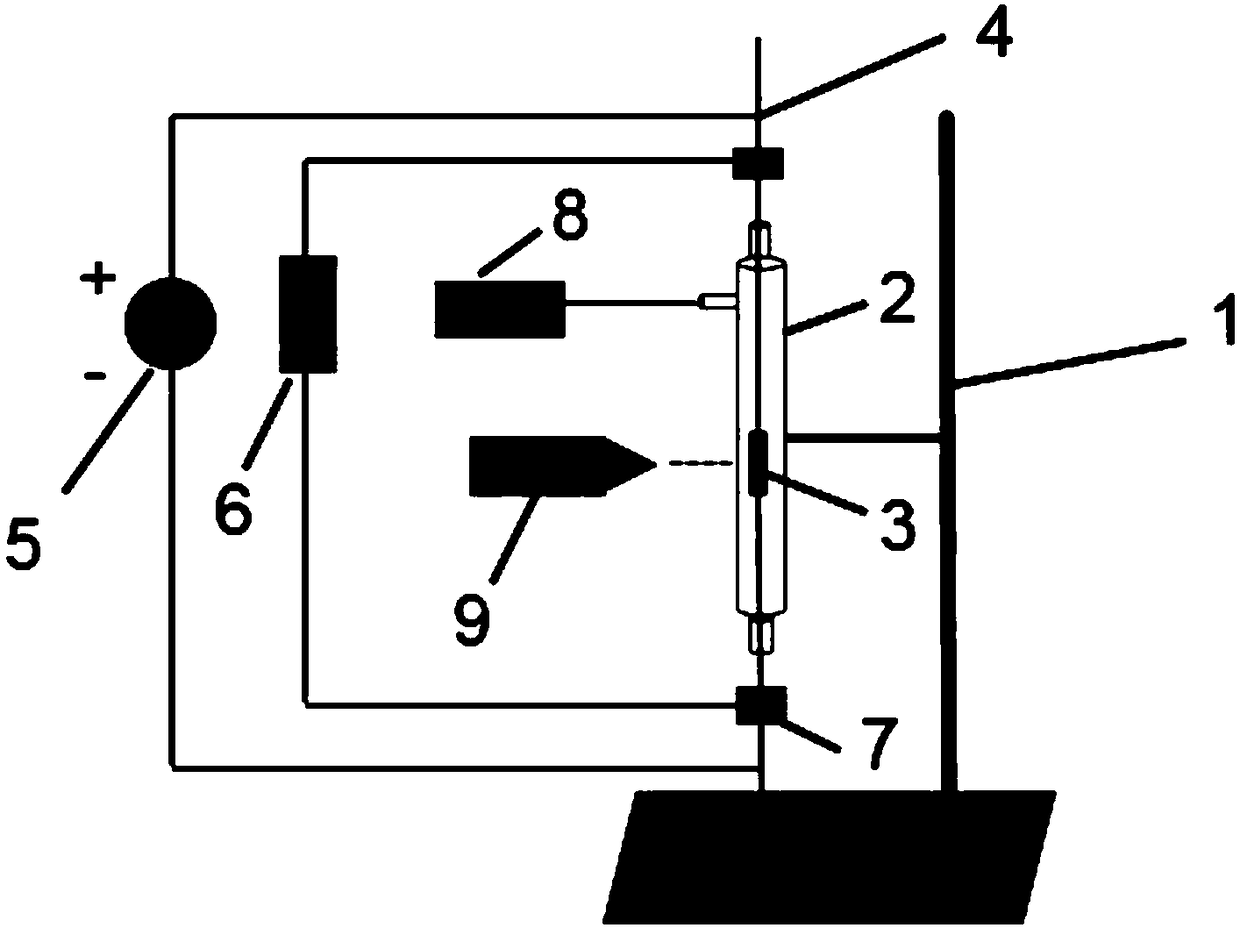

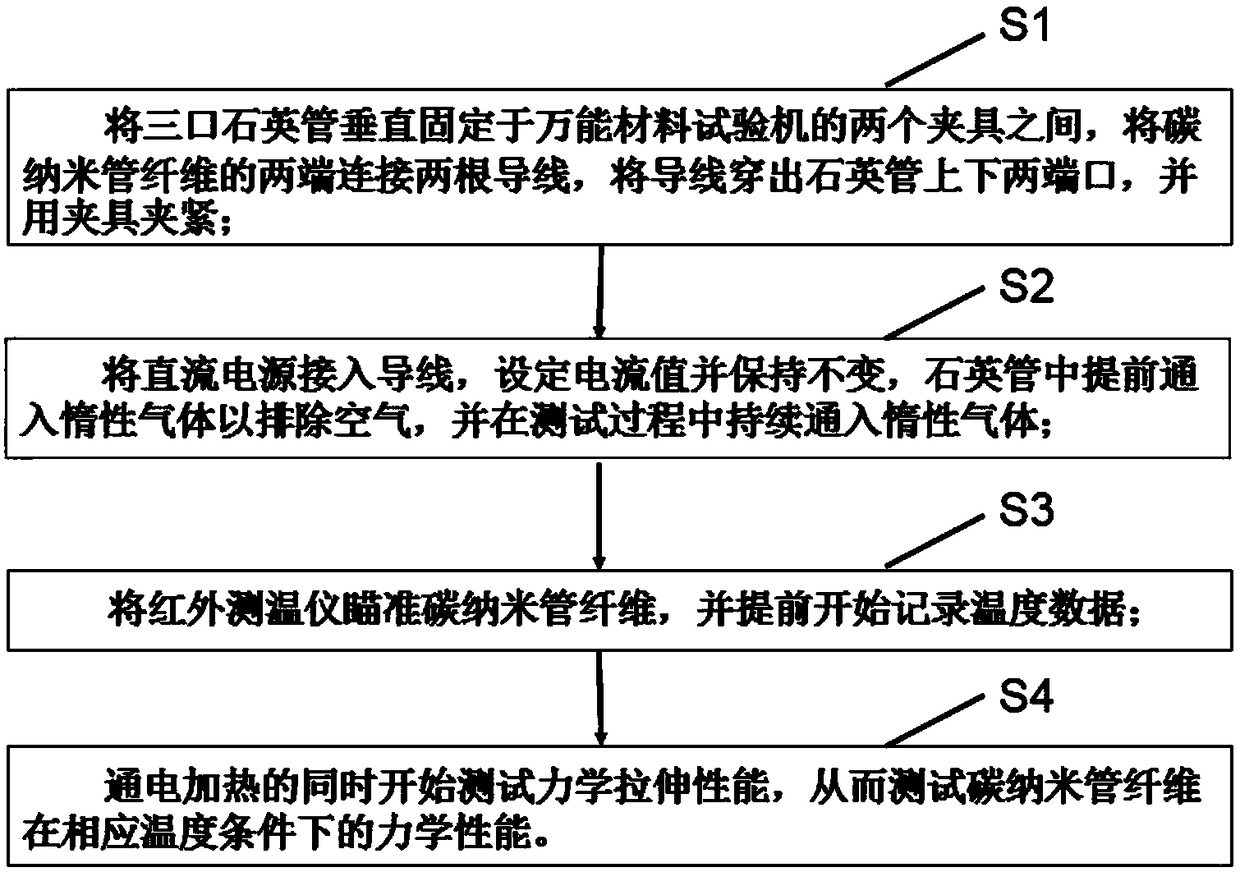

[0054] The carbon nanotube fiber prepared by the floating catalytic method is connected to both ends of the carbon nanotube fiber with a copper wire, and the copper wire is passed through the upper and lower ports of the quartz tube, and the wire is clamped with two clamps of a universal material testing machine, and the carbon nanotube fiber stay vertical;

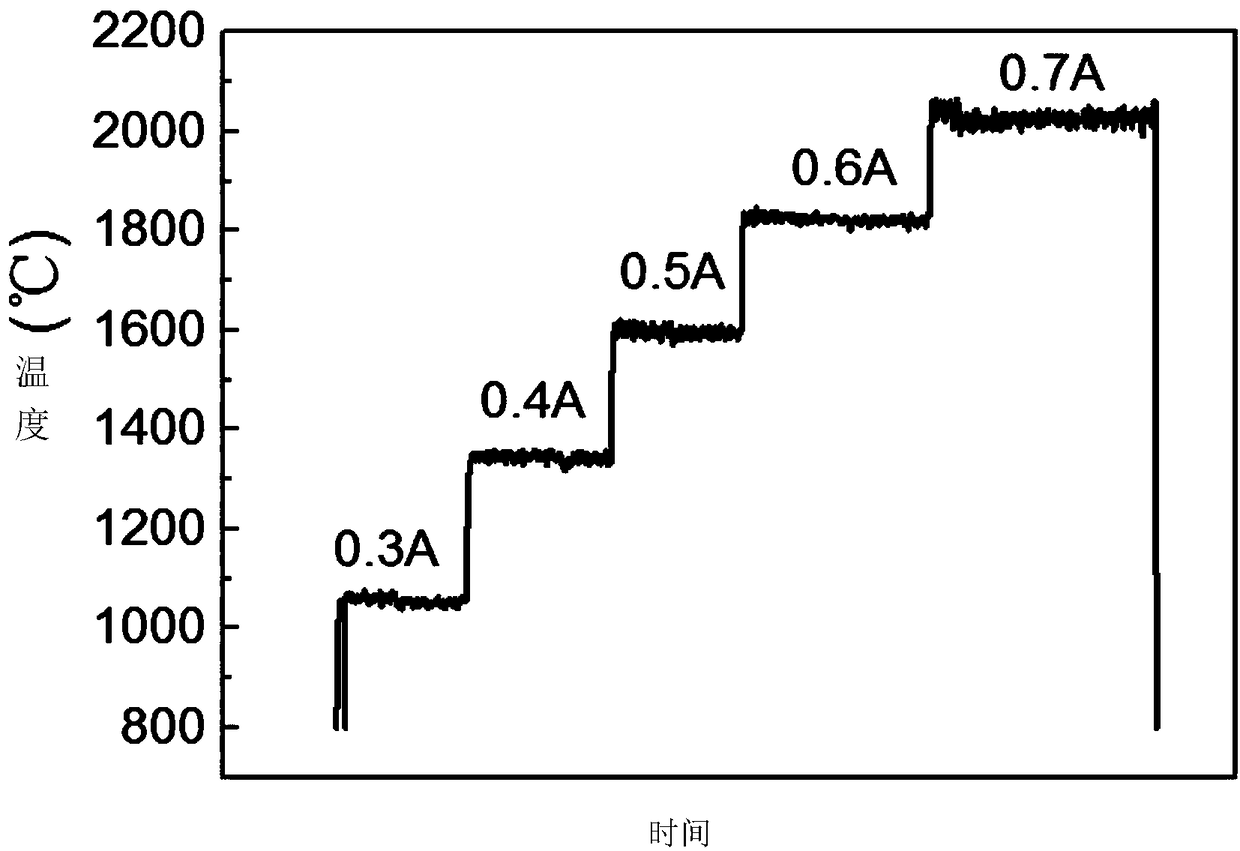

[0055] Connect the DC power supply to the wire, set the current to 0.3A, and keep it constant, pass the inert gas into the quartz tube in advance, ventilate for one minute to remove the air, and continue to pass the inert gas during the test;

[0056] Aim the eyepiece of the infrared thermometer at the middle of the carbon nanotube fiber, and turn on the infrared test switch in advance to record the temperature change of the carbon nanotube fiber during the electrification process;

[0057] Simultaneously turn on the DC power supply and the start button of the universal material testing machine to test the mechanical prop...

Embodiment 2

[0059]The current of the DC power supply is set to 0.4A, and the temperature of the carbon nanotube fiber is 1340°C. The rest of the steps are the same as in Example 1, and the mechanical properties of the carbon nanotube fiber are tested at a temperature of 1340°C. The test results are as follows Figure 4 shown.

Embodiment 3

[0061] The current of the DC power supply is set to 0.5A, the temperature of the carbon nanotube fiber is 1600°C, and the rest of the steps are the same as in Example 1. The mechanical properties of the carbon nanotube fiber are tested at a temperature of 1600°C. The test results are as follows Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com