Six-axis linkage electric discharge machining tool kinematic optimization control method based on spinor

A six-axis linkage and processing machine tool technology, which is applied in the direction of electrical program control, digital control, program control, etc., can solve the problems of unstable discharge state and speed fluctuation, and achieve the effect of optimizing processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

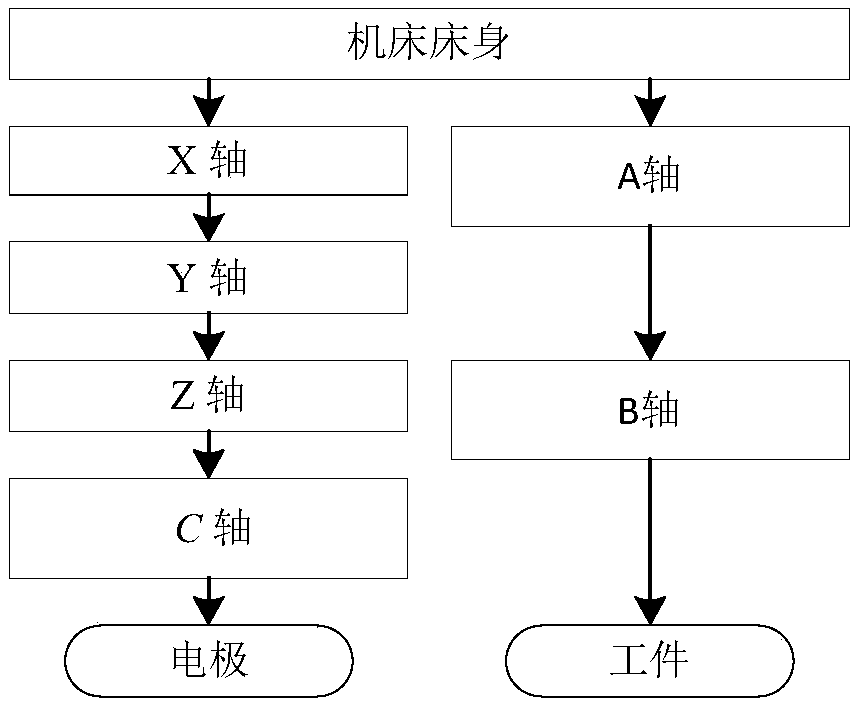

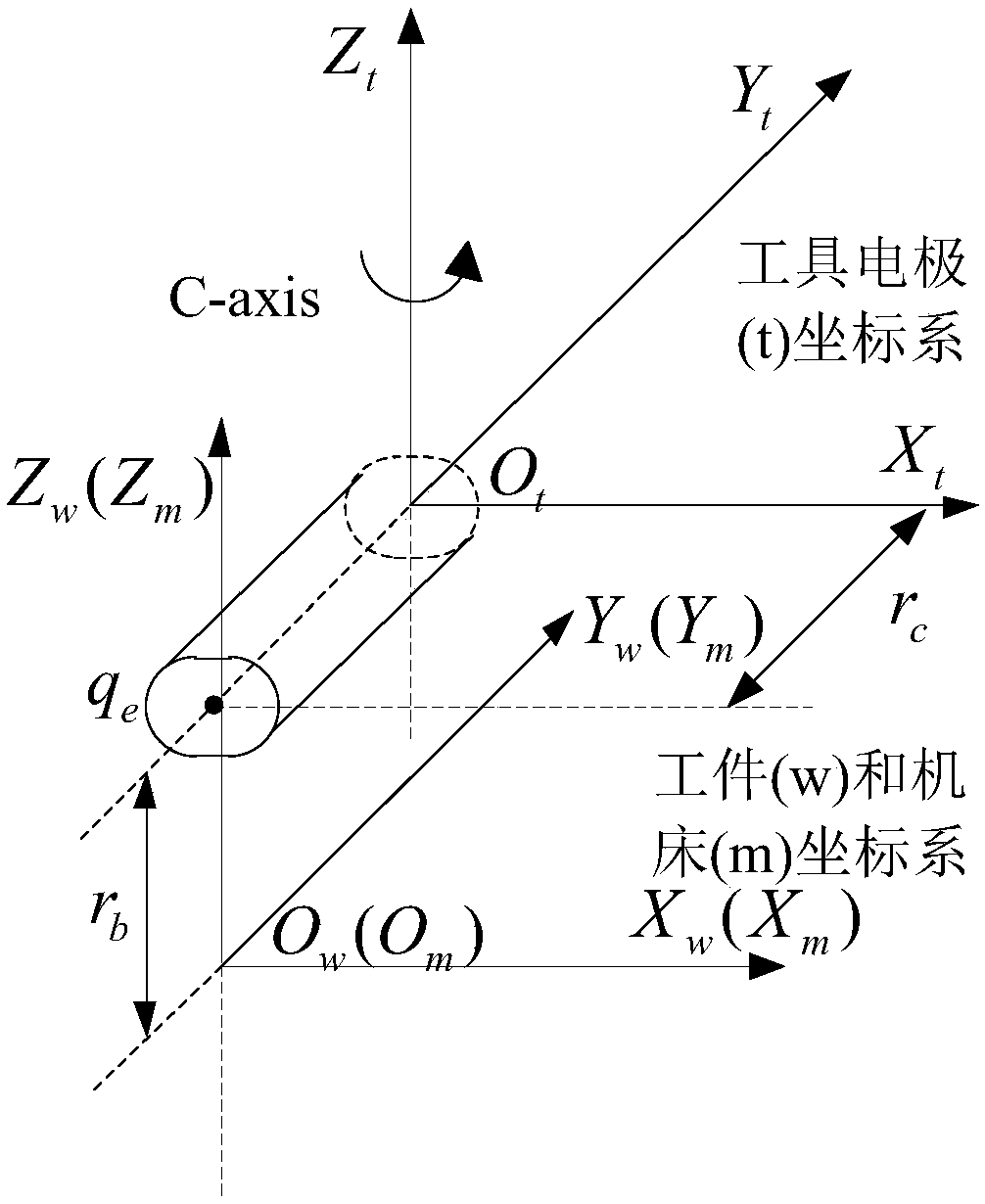

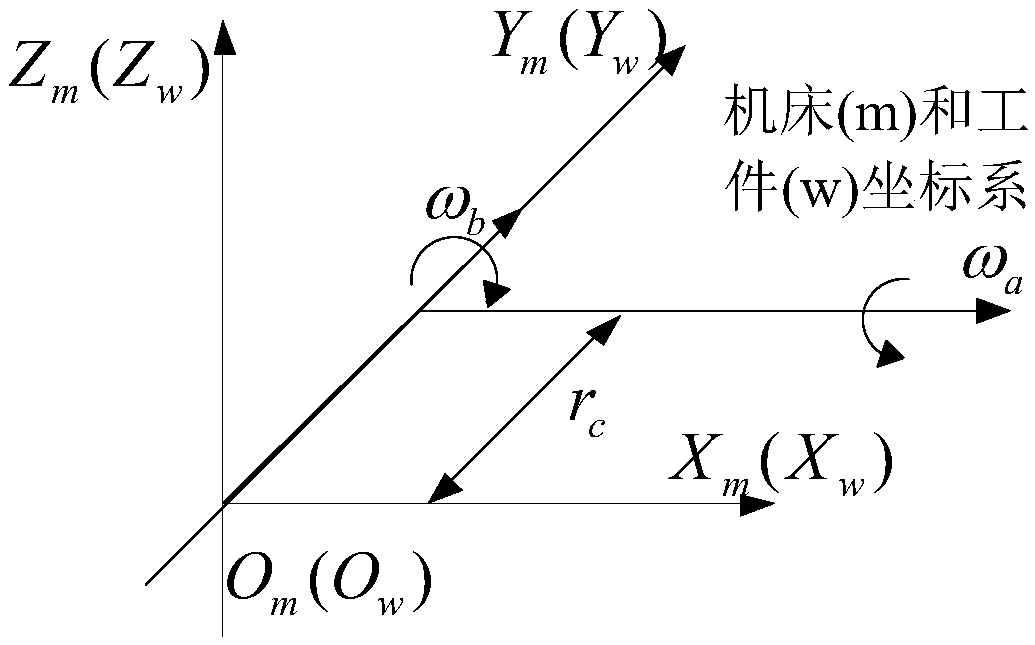

[0016] In this embodiment, the motion of the machining tool and the workpiece in EDM is simulated as the rigid body motion in the six-dimensional special Euclidean group SE(3), which is a three-dimensional real vector space and the product space of the special orthogonal group SO(3), where SO(3) is the space describing the rotation about the origin of the coordinate system.

[0017] where: p is a three-dimensional vector, R is a special orthogonal matrix, is a three-dimensional real vector space, SO(3) is a special orthogonal group, which is a space describing the rotation around the origin of the coordinate system.

[0018] According to the screw theory, all rigid body motion can be decomposed into translational motion along the coordinate axis and rotational motion around the rotational axis. The combination of translational motion and rotational motion can be represented by a motion screw ξ, and the coordinates of ξ can be in the six-dimensional real vector space Ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com