A single-core elbow high-voltage connector

A high-voltage connector and single-core technology, which is applied in the direction of connection, two-part connection device, and parts of the connection device, can solve the need for mutual alignment between the plug and socket assembly and locking, the inconvenient insertion and removal of the plug and socket, and the impact Problems such as the overall appearance of the plug, to achieve the effect of improving the waterproof and dustproof ability, occupying a small space, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

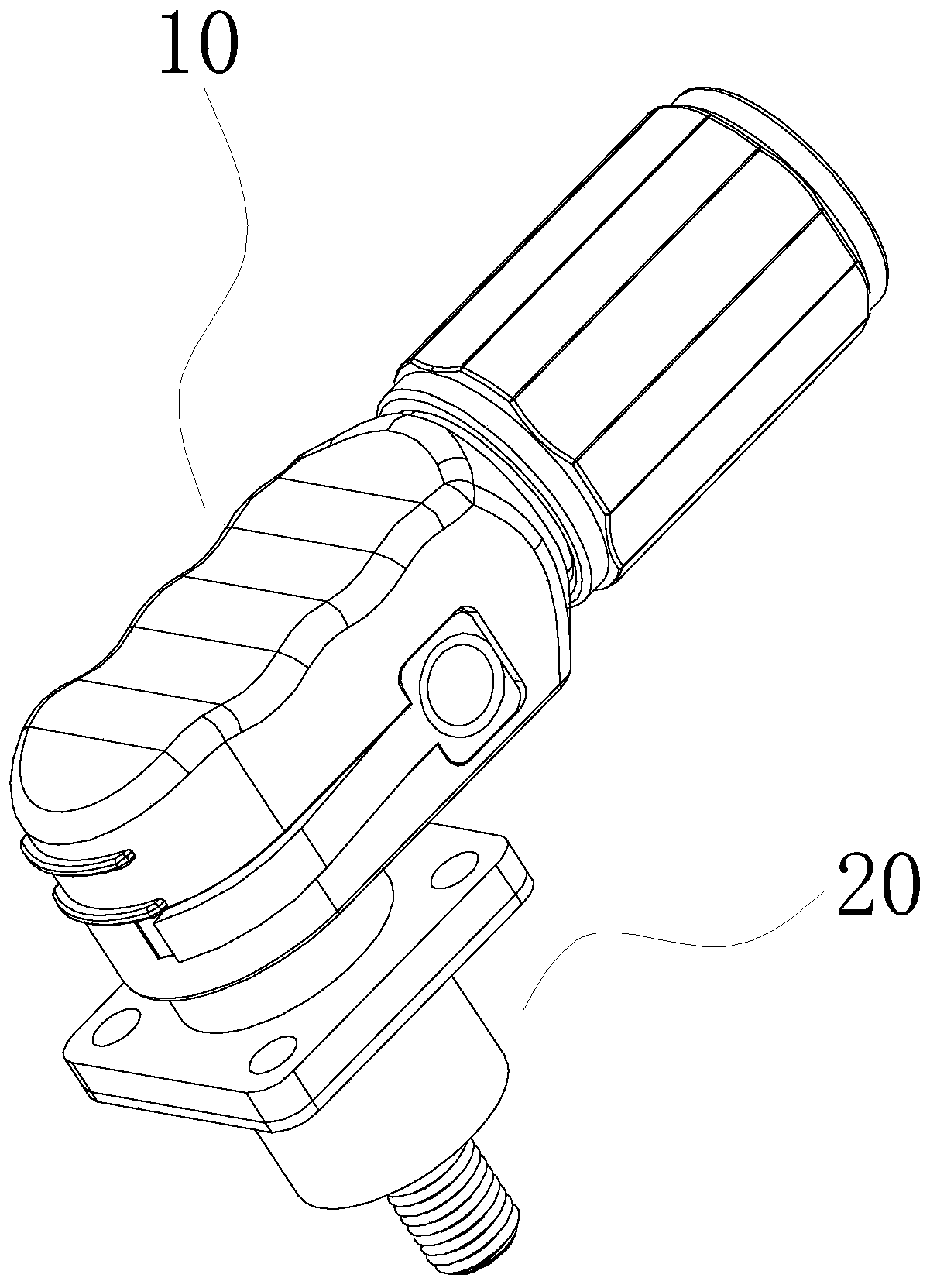

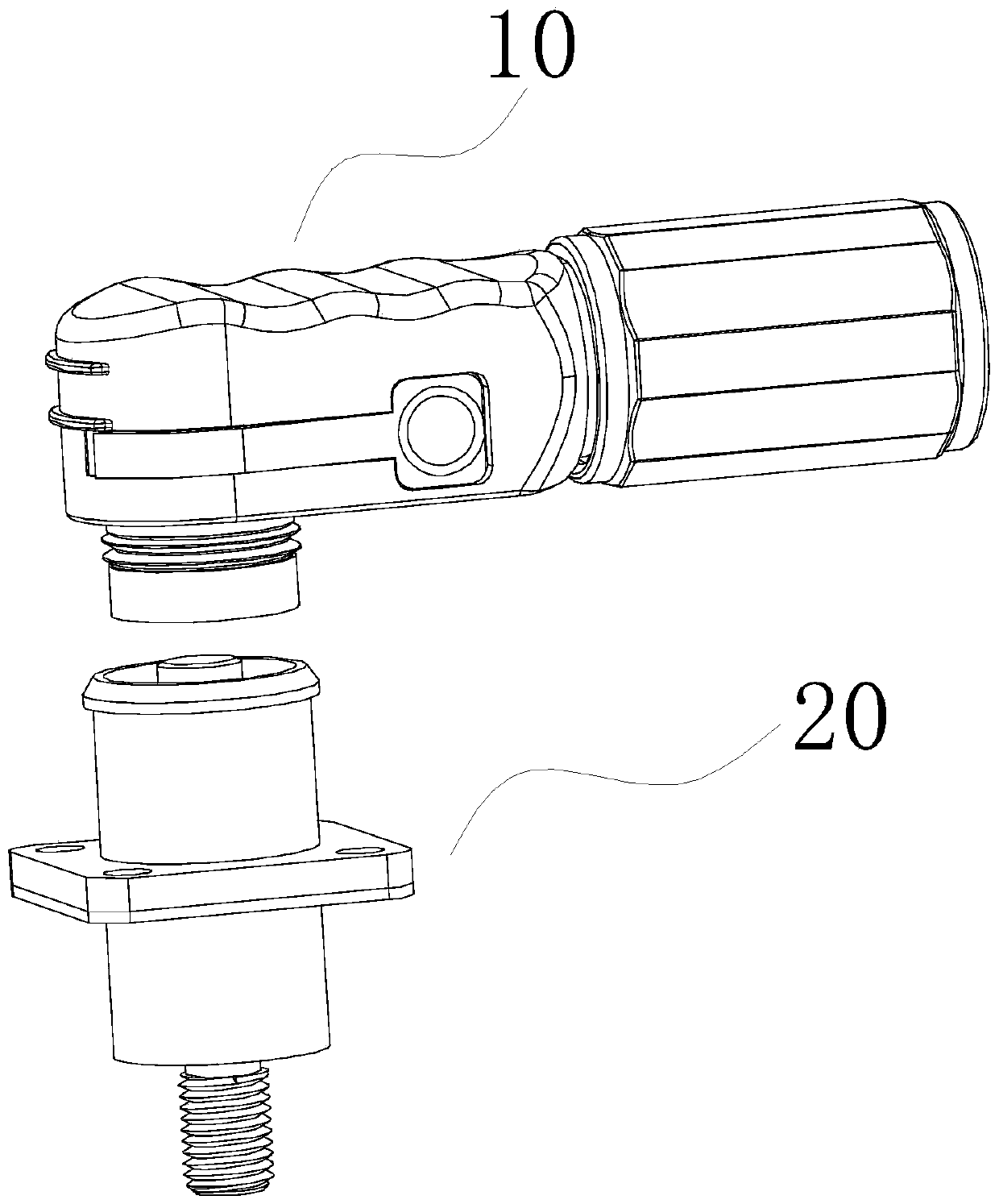

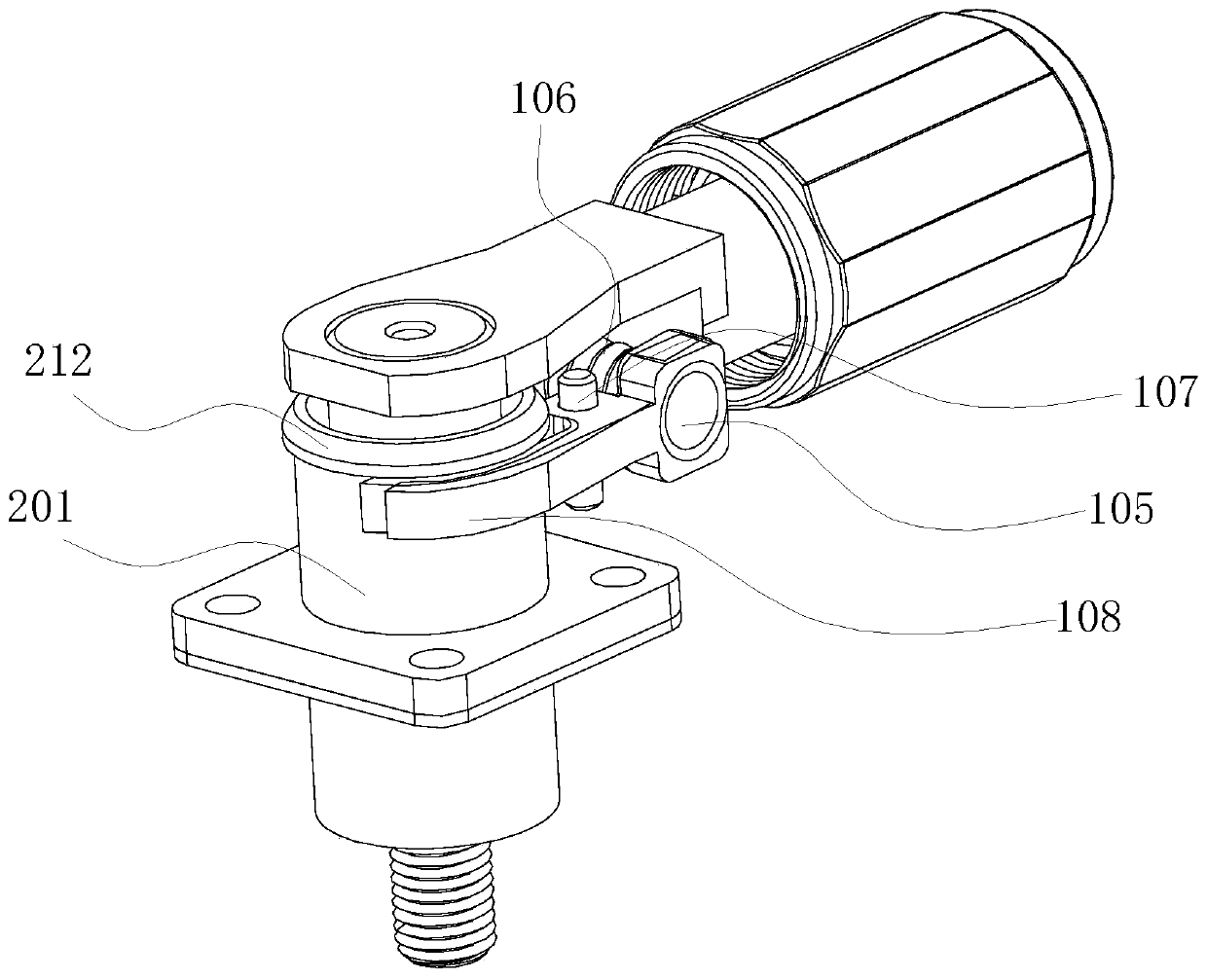

[0031] see Figure 1 to Figure 9 As shown, a single-core elbow high-voltage connector provided in this embodiment includes a plug 10 and a socket 20 that are mated to each other, see figure 2 As shown, the plug 10 is provided with a horizontal section and a vertical section, and the vertical section is detachably inserted into the socket 20, see image 3 , Figure 5 , Figure 7 and Figure 9 As shown, the plug housing 101 is fixedly provided with a spring 106 and a lever assembly. The lever assembly includes a support column 107 fixed on the plug housing 101 (as a fulcrum of the lever structure), a button end 105 and a cantilever end 108. One end of the spring 106 is connected to The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com