Double-stator permanent magnet synchronous motor

A permanent magnet synchronous motor and double stator technology, which is applied in the direction of electrical components, electromechanical devices, and magnetic circuit static parts, can solve the problems of large magnetomotive force harmonic content of fractional slot windings, large number of coils of fractional slot windings, The problem of large eddy current loss of the permanent magnet of the rotor, etc., achieves the effect of less number of armature slots and coils, less eddy current loss, and less harmonic content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

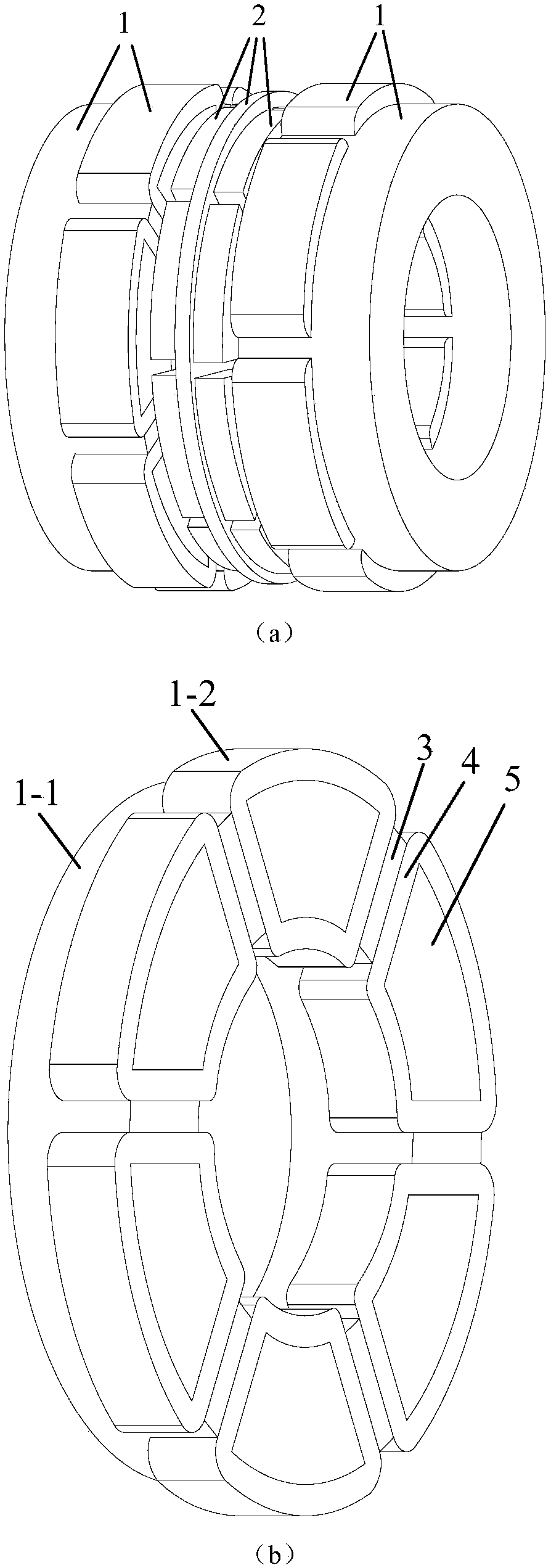

[0058] figure 1 It is Example 1 of the present invention. The double-stator permanent magnet synchronous motor of the present embodiment is made up of two stators 1 and rotor 2,

[0059] The rotor 2 and the two stators 1 are arranged axially, the rotor 2 is located between the two stators 1, there is an air gap between the rotor 2 and the two stators 1, and each stator 1 consists of a stator core 1-1 and a stator winding 1 -2 composition; 12 slots are radially opened on the air gap side surface of each stator core 1-1, and the formed small teeth 3, slots 4 and large teeth 5 are arranged alternately along the circumferential direction, and the pitch of the large teeth is t s2 and polar distance τ p satisfies the relation 3t s2 =4τ p ;Large tooth width b s2 , small tooth pitch t s1 , small tooth width b s1 satisfies the relation b s2 = 2t s1 +b s1 , the stator windings 1-2 are concentrated full-pitch windings, one coil is wound on each large tooth 5, the coils on adja...

Embodiment 2

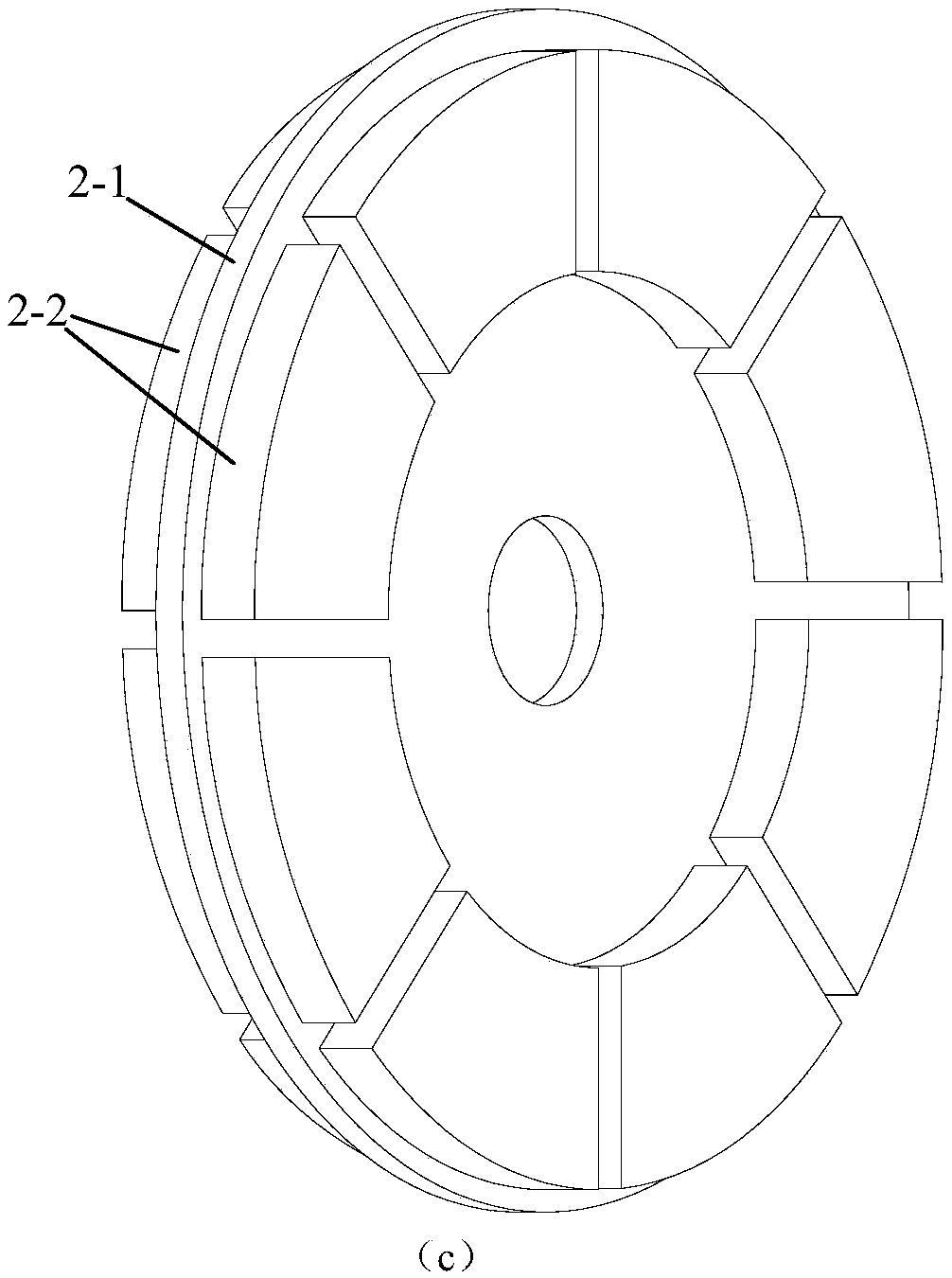

[0062] figure 2 It is Example 2 of the present application. The dual-stator permanent magnet synchronous motor of the present embodiment comprises two stators 1 and a rotor 2,

[0063] The rotor 2 and the two stators 1 are arranged axially, the rotor 2 is located between the two stators 1, there is an air gap between the rotor 2 and the two stators 1, and each stator 1 consists of a stator core 1-1 and a stator winding 1 -2 composition; the surface of each stator core 1-1 air gap side is smooth, and the primary winding is fixed on the surface of the stator core 1-1 air gap side, the primary winding is composed of concentrated coils, and the 6 coils constituting the three-phase winding are along the circumference The directions are arranged in sequence, the coils do not overlap, the adjacent coils belong to different phases, and the distance between the centers of adjacent coils is t c and polar distance τ p satisfies the relation 3t c =4τ p , all the coils on each stator...

Embodiment 3

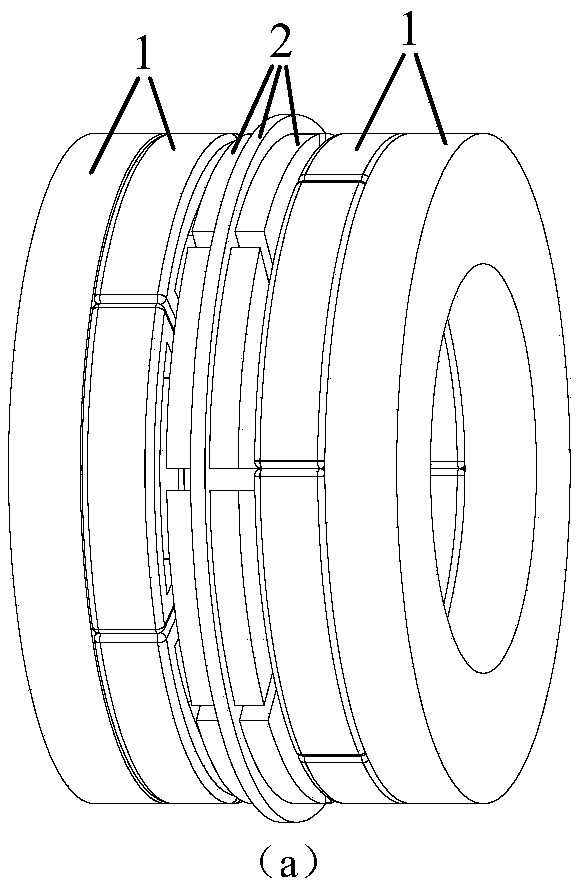

[0066] image 3 It is Example 3 of the present application. The double-stator permanent magnet synchronous motor of the present embodiment is made up of two stators 1 and rotor 2,

[0067] The rotor 2 and the two stators 1 are arranged axially, the rotor 2 is located between the two stators 1, there is an air gap between the rotor 2 and the two stators 1, and each stator 1 consists of a stator core 1-1 and a stator winding 1 -2 composition; 12 slots are opened in the axial direction on the air gap side surface of each stator core 1-1, and the formed small teeth 3, slots 4 and large teeth 5 are arranged alternately along the circumferential direction, and the pitch of the large teeth is t s2 and polar distance τ p satisfies the relation 3t s2 =4τ p ;Large tooth width b s2 , small tooth pitch t s1 , small tooth width b s1 satisfies the relation b s2 = 2t s1 +b s1 , the stator windings 1-2 are concentrated full-pitch windings, one coil is wound on each large tooth 5, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com