Resonant asynchronous motor and its control method

A technology for asynchronous motors and control methods, applied in motor control, motor generator control, asynchronous induction motors, etc., can solve the problems of low efficiency, low motor efficiency and power factor, etc., to reduce eddy current loss, improve utilization, Extremely high dynamic response quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

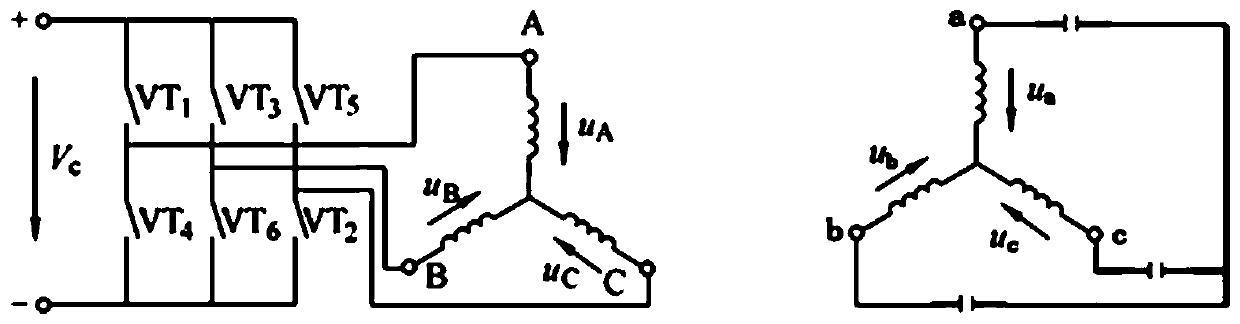

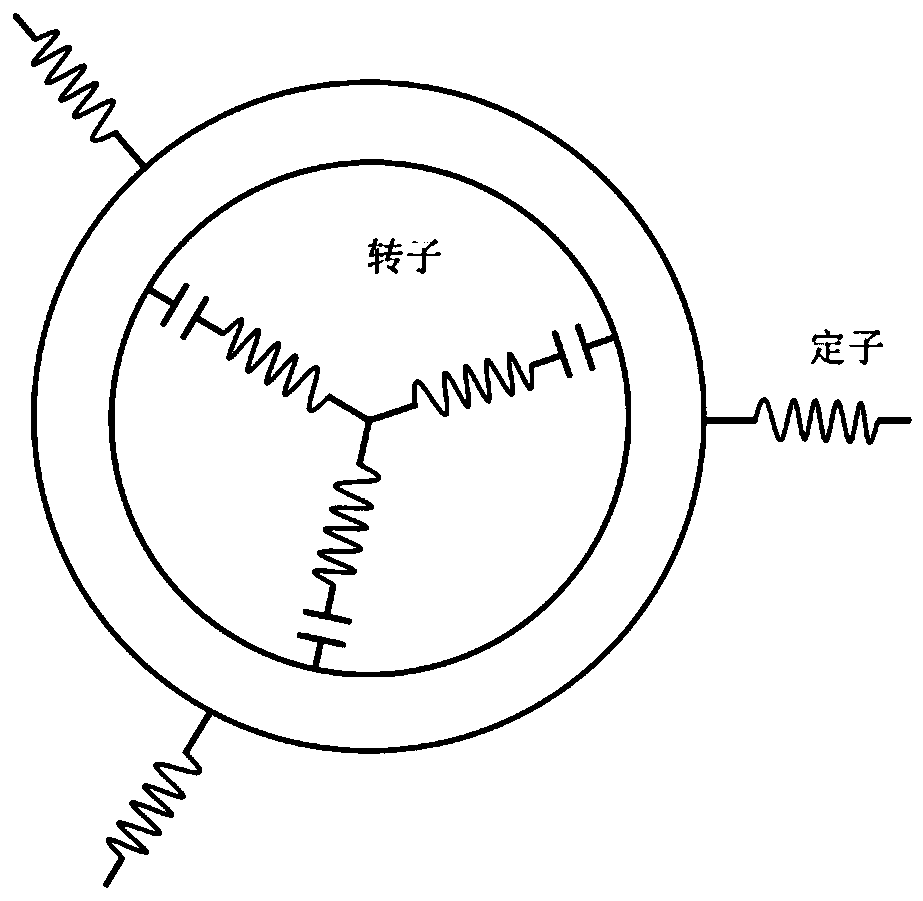

[0037] Such as figure 1 and figure 2 As shown, in the resonant asynchronous motor of this embodiment, the stator winding and the rotor winding are both provided with three phases, and the three phases of the rotor winding are symmetrical and have a 120° space (electrical) angle difference. Due to the existence of the space angle difference of the rotor winding, according to electromechanical The principle is easy to know, when there is current passing through the rotor, an equivalent space current vector can be formed.

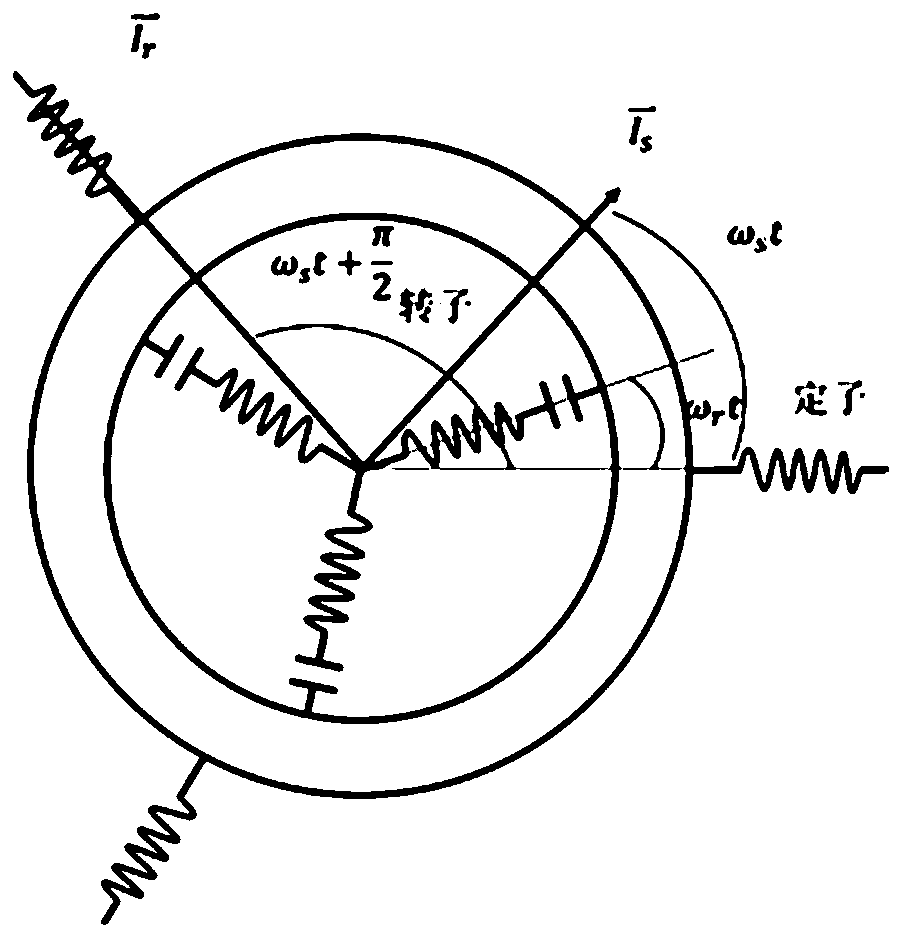

[0038] Assuming that the air-gap magnetic field is sinusoidally distributed, the current in the stator coil can be represented by a vector. When the stator three-phase current is injected according to the sinusoidal law, the current vector rotates in space. The specific method is: control the stator three-phase current I 4 (t), I B (t), I C (t) In the case of steady state, it is a symmetrical AC, that is, the amplitude of each current is the same, and the...

Embodiment 2

[0055] In the resonant asynchronous motor of this embodiment, the rotor winding is set as a two-phase LC resonant winding, which are called d and q windings respectively. The two windings are independent and orthogonal to each other. The topology is as follows: Figure 4 shown. Due to the existence of the space angle difference between the two windings, when there is current passing through the two windings, a changing space current vector can be formed.

[0056] The stator structure and stator current control method in this example are consistent with those in Embodiment 1.

[0057] The electrical characteristics of the motor are analyzed below, see Figure 5 marked. Secondary factors such as saturation and current harmonics are ignored in the following analysis.

[0058] The stator current is the same as that in Embodiment 1 and will not be repeated here.

[0059] The dq coordinate system is a coordinate system fixed to the rotor, and the d-axis direction and the q-axis ...

Embodiment 3

[0083] The resonant asynchronous motor in this embodiment is provided with an auxiliary excitation circuit / device to improve the output characteristics of the motor. Combined with the design of the rotor with two orthogonal coils, the analysis is carried out.

[0084] This embodiment is mainly considered from two perspectives, one is the current form of the two coils of the rotor, and the other is to determine the control method of the rotor end according to the current form required by the above rotor coils.

[0085] The following is discussed in conjunction with the design of the non-contact MCR-WPT, and the principle of the contact type is similar to this.

[0086] 1) Rotor target current equation

[0087] It is set that there are two coils on the physical dq axis of the rotor, such as Figure 6 As shown, the currents of the two coils are respectively:

[0088] I d (t)=I r cos(ω 0 t)

[0089]

[0090] The current of the two coils can be synthesized into a current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com