A kind of production technology of Pixian watercress continuous closed post-ripening fermentation

A production process and post-ripening fermentation technology, applied in the production process of Pixian Douban, can solve the problems of affecting the flavor and taste of the product, loss of volatile substances, and different product quality, and achieve a complex flavor that is full and rich, and the color is bright and ruddy. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

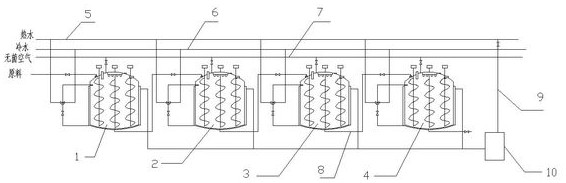

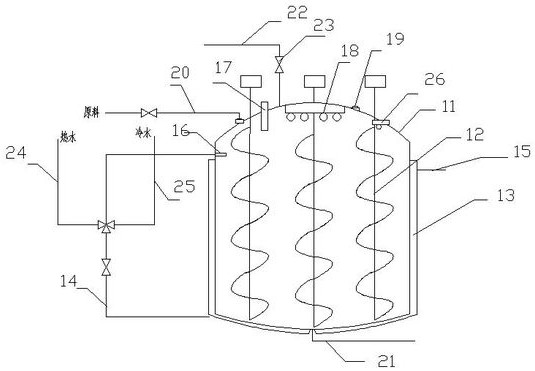

[0053] In this embodiment, a fully enclosed fermenter is used for fermentation. A total of four fermenters are used for fermentation, namely, fermenter I1, fermenter II2, fermenter III3, and fermenter IV4. The specific structures of each fermenter are the same. Specifically:

[0054] Including a tank body 11 and a stirring paddle 12, at least two stirring paddles 12, the stirring paddle 12 is installed in the tank body 11, the tank body 11 is equipped with a jacket layer 13, and the jacket layer 13 is connected with a water inlet pipe 14 and a water outlet pipe 15 , a temperature detector 16, a humidity detector 17, an ultraviolet lamp and a fluorescent lamp 18 are installed in the tank body 11, and the tank body 11 is provided with a feed inlet, a discharge outlet, a sterile dry air inlet and an exhaust outlet 19, The feeding port is connected with a feed pipe 20, the discharge port is connected with a discharge pipe 21, the sterile dry air inlet is connected with an air inta...

Embodiment 2

[0077] Each fermenter that this implementation adopts is identical with embodiment 1, and difference is:

[0078] The process of this embodiment is:

[0079] Step 1, raw materials into the fermenter Ⅰ

[0080] Add the fermented mature pepper embryos and sweet petals into the fermenter I according to the mass ratio of 7:3;

[0081] Step 2, fermentation in fermenter Ⅰ

[0082] After the temperature of the fermenter I was raised to 30°C, after 12 hours of heat preservation and fermentation, salt was added to the reactor;

[0083] Step 3, Fermentation Tank II Fermentation

[0084] Transfer 2 / 3 of the total mass of bean paste in fermenter Ⅰ to fermenter Ⅱ, add salt to fermenter Ⅱ, and add mature bean paste to fermenter Ⅱ during the first fermentation in fermenter Ⅱ. 14 cycles of fermentation were carried out, and the fermentation operation of each cycle was as follows: after the fermentation temperature was raised to 55°C, heat preservation and fermentation for 4 hours, and the...

Embodiment 3

[0094] Each fermenter that this implementation adopts is identical with embodiment 1, and difference is:

[0095] The process of this embodiment is:

[0096] Step 1, raw materials into the fermenter Ⅰ

[0097] Add the fermented mature pepper embryos and sweet petals into the fermenter Ⅰ according to the mass ratio of 7:2.5;

[0098] Step 2, fermentation in fermenter Ⅰ

[0099] After the temperature of the fermenter I was raised to 28°C, after 15 hours of heat preservation and fermentation, salt was added to the reactor;

[0100] Step 3, Fermentation Tank II Fermentation

[0101] Transfer 7 / 12 of the total mass of bean paste in fermenter Ⅰ to fermenter Ⅱ, add salt to fermenter Ⅱ, and add mature bean paste to fermenter Ⅱ during the first fermentation in fermenter Ⅱ. 11 cycles of fermentation were carried out in the middle, and the fermentation operation of each cycle was as follows: after the fermentation temperature was raised to 52°C, the temperature was kept for 4.5 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com