Jelly gel making device

A technology of jelly gel and production equipment, which is applied in food forming, food science, application, etc., can solve the problems of cumbersome steps and low production efficiency, and achieve the effects of simplifying production steps, improving production efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

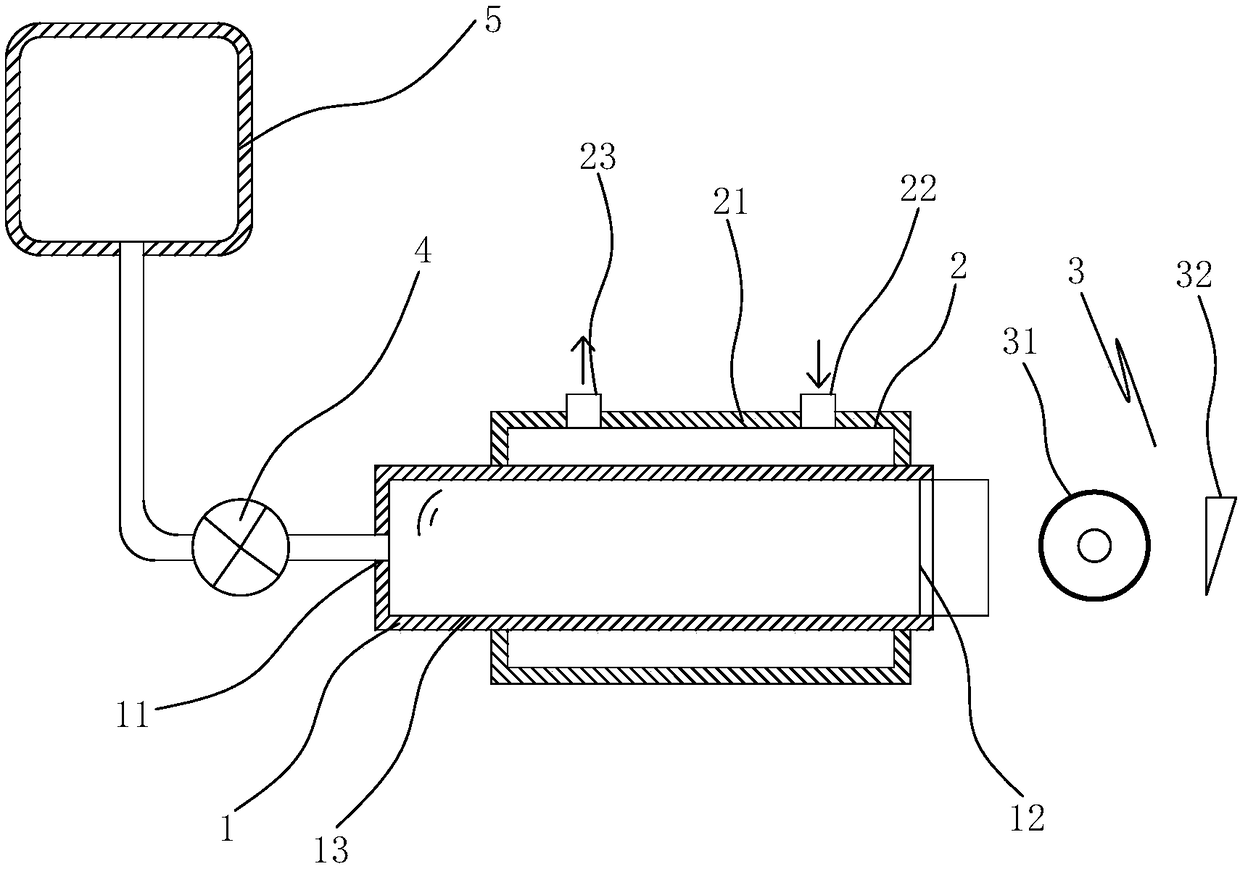

[0026] refer to figure 1 As shown, a jelly gel manufacturing device includes a feed liquid pipe 1, a cooling pipe 2, a delivery pump 4, a cutter assembly 3 and a hopper 5;

[0027] The hopper 5 is used to store the jelly feed liquid to be cooled;

[0028] The feed liquid pipe 1 is connected to the hopper 5, and is provided with a feed inlet 11, a feed outlet 12, and a feed liquid passage 13 extending from the feed inlet 11 to the feed outlet 12, and the jelly feed liquid enters the feed liquid passage from the feed inlet 11 13. It is cooled into a jelly gel in the rear section of the feed liquid channel 13, and then extruded from the discharge port 12. Specifically, the feed liquid channel 13 is flat, that is, the cross section of the feed liquid channel 13 is rectangular, so that The jelly feed liquid entering from the feed port 11 can be diffused and spread to fill the feed liquid channel 13, so that the heat exchange efficiency between the jelly feed liquid and the cooling...

Embodiment 2

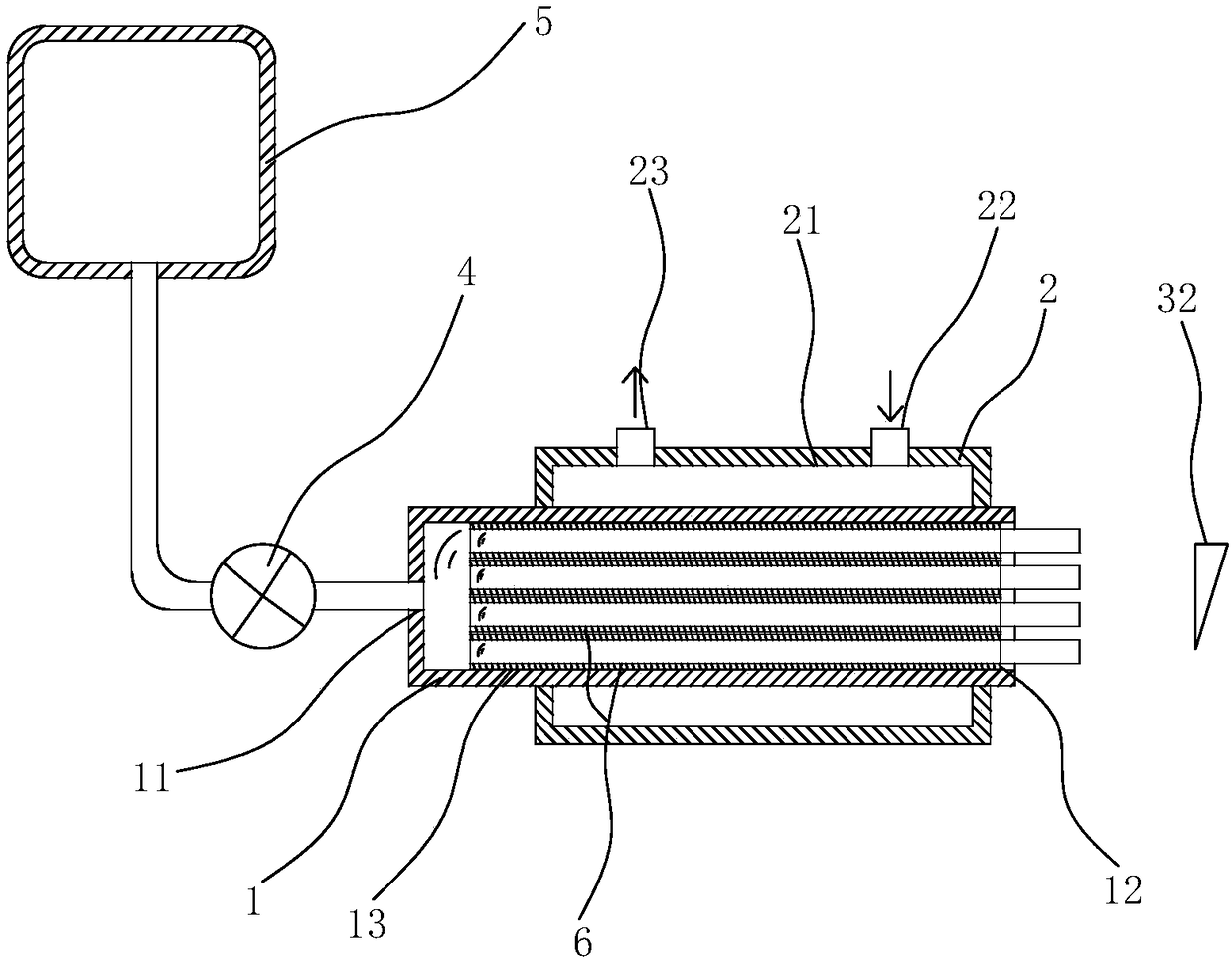

[0034] refer to Figure 2 to Figure 3 Shown, its basic structure is identical with embodiment 1, and its difference is that a plurality of shaping tubes 6 are arranged in the feeding liquid pipe 1, and the jelly feeding liquid enters the feeding liquid channel 13 through the feeding port 11 and then enters the shaping pipe 6, It is cooled and formed in the shaping tube 6. Specifically, one end of the shaping tube 6 is close to the feed inlet 11, and the other end extends to the outlet port 12 along the flow direction of the jelly feed liquid. Adaptive changes in the shape of the gel;

[0035] Correspondingly, the cutter assembly 3 includes a dicing knife 32 for dicing the cooled and formed jelly gel, and the jelly liquid is cooled into a cylindrical shape in the shaping tube 6, and only the dicing knife 32 is needed in the later stage to cool and shape the jelly gel. cut the jelly gel into cubes;

[0036] The working principle of the jelly gel production device: the jelly fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com