Domestic garbage processing system and processing method thereof

A treatment system and technology for domestic waste, applied in combustion methods, chemical instruments and methods, lighting and heating equipment, etc., can solve the problems of inability to quickly reduce the moisture content of waste, leachate pollutes the environment, and difficulty in sorting, etc. The difficulty of garbage sorting, the improvement of garbage recycling efficiency and the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

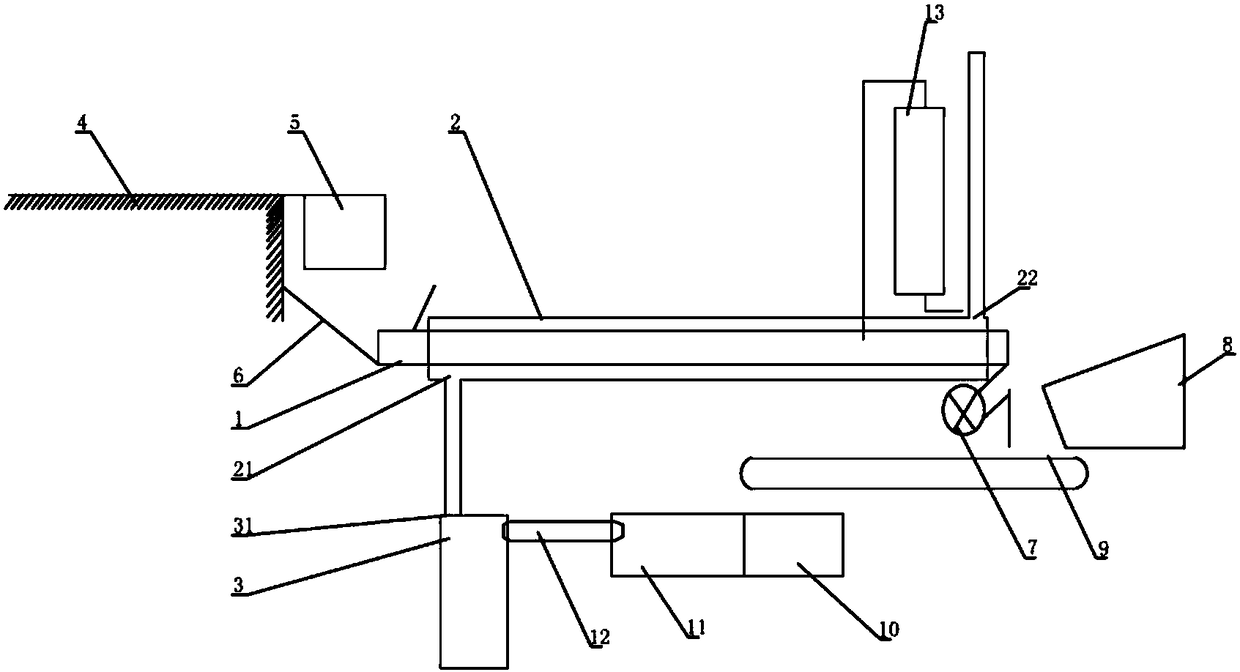

[0034] The present invention is a kind of household garbage processing system, which includes a crushing module for breaking bags and shredding garbage, a drying module for drying garbage, a sorting module for winnowing and sorting, and a combustion and decomposition module. Garbage gasification module;

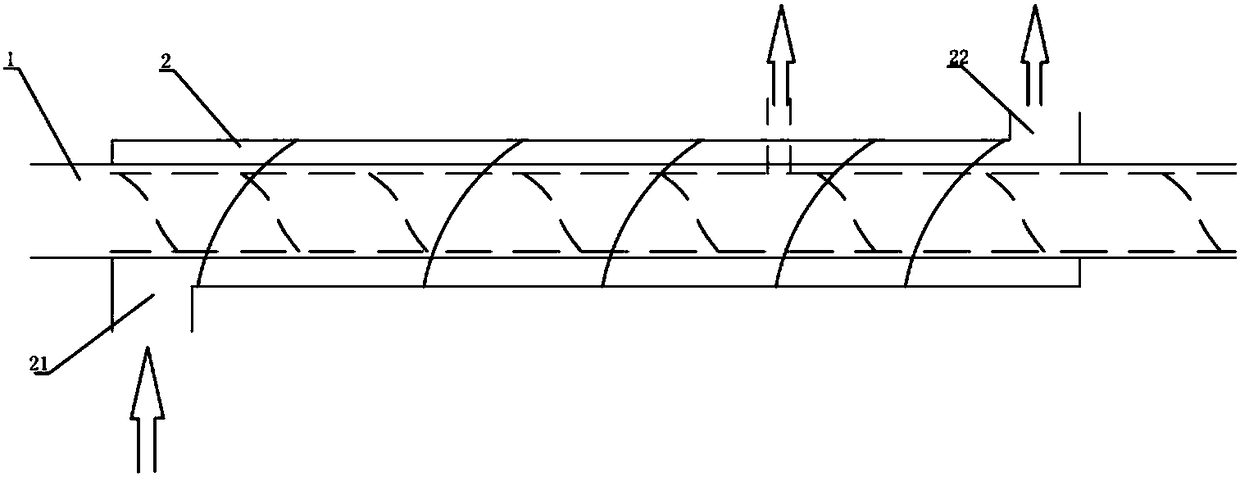

[0035] The drying module includes a spiral drying pipe 1, and the garbage treatment system also includes a flue gas heating pipe 2, and the flue gas heating pipe wraps the spiral drying pipe;

[0036] The gasification module at least includes a gasification furnace 3, the gasification furnace is provided with a flue gas outlet 31, and the flue gas heating pipeline 2 is provided with a flue gas inlet 21 and a flue gas outlet 22, and the flue gas heating pipeline The flue gas inlet is communicated with the flue gas outlet of the gasifier through a pipeline;

[0037] The processing system also includes a discharge platform 4 for unloading, the crushing module includes a bag-bre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com