Carbon fiber electric heating core without support body and demolding method thereof

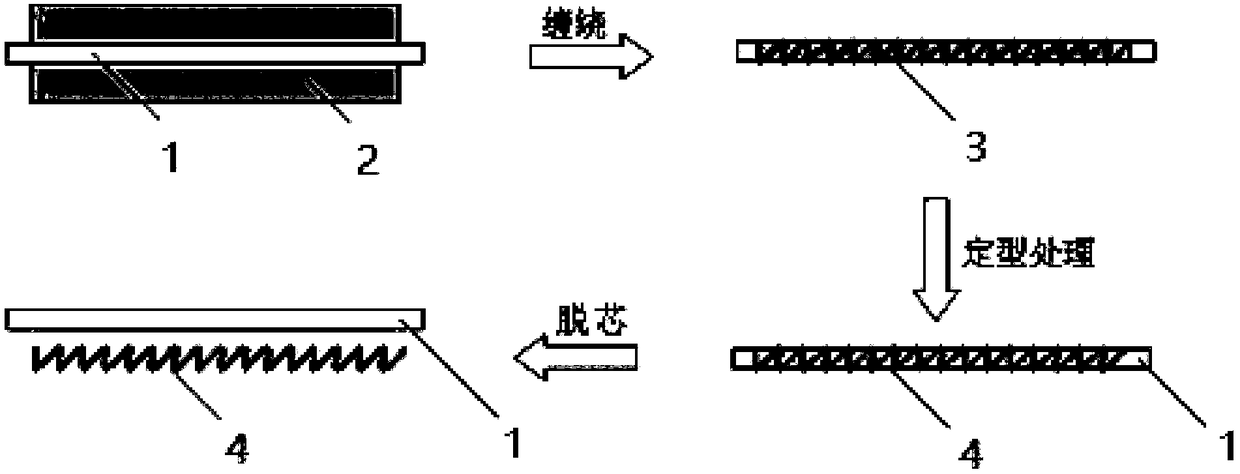

A carbon fiber and electric heating core technology, applied in the field of carbon fiber infrared electric heating core preparation, can solve the problems of high scrap rate, low demoulding efficiency, poor quality, etc., and achieve favorable detachment, good demoulding effect, and stable demoulding gap uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. A release agent for unsupported carbon fiber electric heating core demoulding, said release agent comprising the following raw materials: paraffin wax, graphite powder, wherein the weight ratio of paraffin wax and graphite powder is 1:1, and the particle size is 500 mesh, mix the above raw materials in proportion and then mix with water to make a paste.

[0042] 2. A release cloth 2 for demoulding a carbon fiber electric heating core without a support body, the release cloth 2 includes: the release agent described in this embodiment, cotton yarn with a porous structure, wherein the paste-like release cloth The mold agent is evenly applied on the surface of the cotton yarn, and the surface density of the release cloth 2 after applying the mold release agent is 100g / m 2 .

[0043] 3. A method for preparing a supportless carbon fiber electric heating core, comprising the following steps:

[0044] (1) Coating the release cloth 2 prepared in this embodiment on the surfa...

Embodiment 2

[0048]1. A release agent for unsupported carbon fiber electric heating core demoulding, said release agent comprising the following raw materials: temperature-resistant silicone grease, powdered graphene, wherein the temperature-resistant silicone grease, powdered graphene The weight ratio is 2:1, and the particle size is 600 mesh. The above raw materials are mixed in proportion and then mixed with water to make a paste.

[0049] 2. A release cloth 2 for demolding a carbon fiber electric heating core without a support body, the release cloth 2 includes: the release agent described in this embodiment, medical gauze with a porous structure, wherein the paste-like The release agent is evenly applied on the surface of the medical gauze, and the surface density of the release cloth 2 after applying the release agent is 80g / m 2 ;

[0050] 3. A method for preparing a supportless carbon fiber electric heating core, comprising the following steps:

[0051] (1) Cover the release cloth...

Embodiment 3

[0055] 1. A release agent for demolding a carbon fiber electric heating core without a support, the release agent includes the following raw materials: temperature-resistant silicone grease, powdered carbon nanotubes, wherein, temperature-resistant silicone grease, powdered carbon nanotubes The weight ratio of the tube is 1.5:1, and the particle size is 550 mesh. The above raw materials are mixed in proportion and then mixed with water to make a paste.

[0056] 2. A release cloth 2 for demoulding a carbon fiber electric heating core without a support body, the release cloth 2 includes: the release agent described in this embodiment, cotton yarn with a porous structure, wherein the paste-like release cloth The mold agent is evenly applied on the surface of the cotton yarn, and the surface density of the release cloth 2 after applying the mold release agent is 120g / m 2 .

[0057] 3. A method for preparing a supportless carbon fiber electric heating core, comprising the followin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com