Eliminating method for tempered seamless steel pipe residual stress and adopted bi-directional chain type cooling bed

A technology of seamless steel pipe and residual stress, applied in the field of heat treatment, can solve the problems of increased oxide scale on the surface of steel pipe, rising cost, occupation of quenching and tempering capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

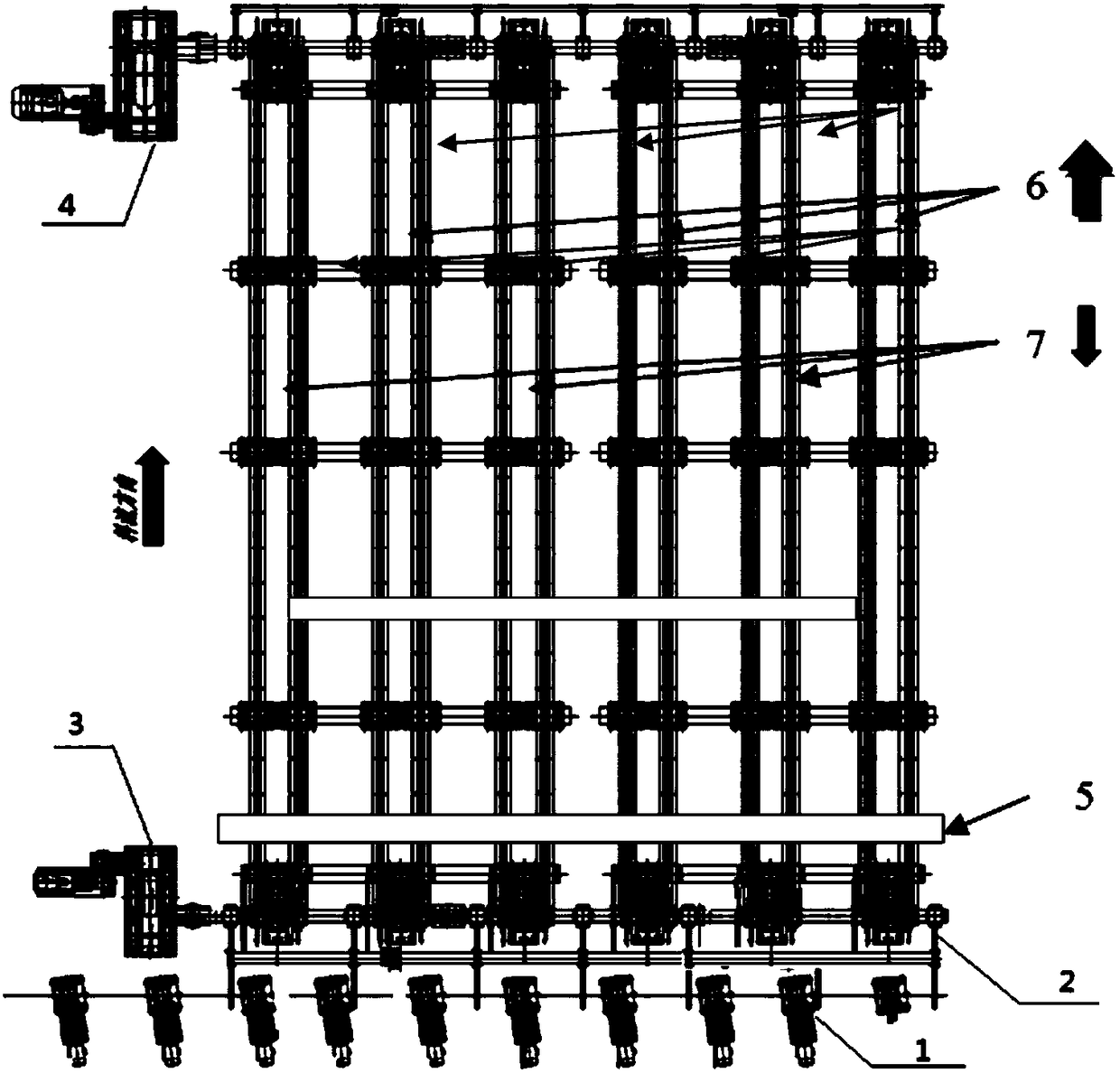

[0055] This embodiment provides a method for eliminating the residual stress of quenched and tempered seamless steel pipe 5, the process steps of the elimination method are as follows:

[0056] (1) The seamless steel pipe 5 whose steel type is 42CrMo and whose specification is 323.9*50.8mm is rolled by a six-roller straightening machine after hot rolling, and the bending degree of the seamless steel pipe 5 after straightening is 1.39mm / m;

[0057] (2) For quenching, use a walking heating furnace for quenching and heating. The quenching heating temperature is 840°C and the holding time is 145 minutes. , when the steel pipe is cooled to 95°C, the cooling water is stopped, and then tempered with a stepping furnace for tempering heating, the heating temperature is 560°C, and the holding time is 345 minutes;

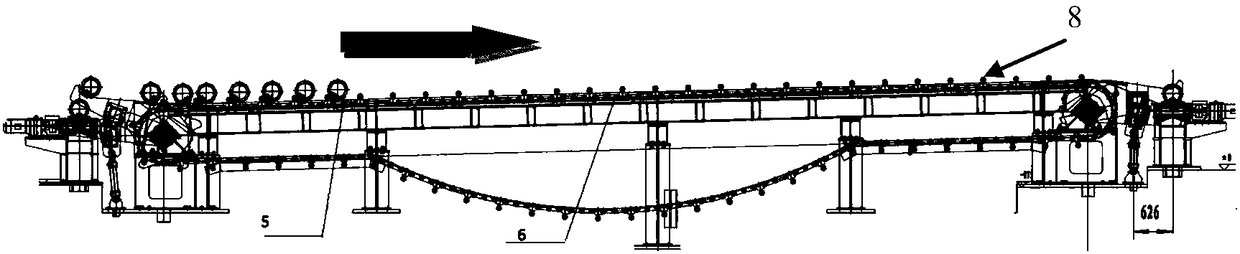

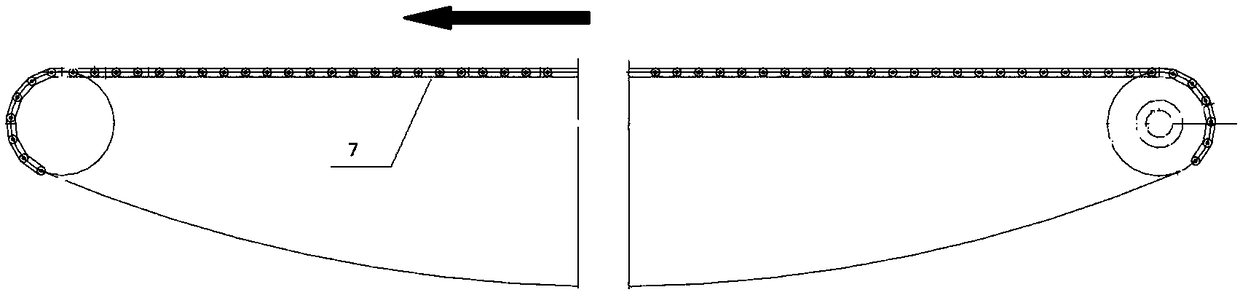

[0058] (3) After the seamless steel pipe 5 leaves the tempering furnace, the seamless steel pipe 5 is placed on the two-way chain cooling bed through the conveying roller tab...

Embodiment 2

[0061] (1) The steel grade is ASTM A519 4140 and the specification is 127*12.7mm seamless steel pipe 5. After hot rolling, a six-roller straightener is used for roll straightening. After straightening, the seamless steel pipe 5 has a curvature of 1.75mm / m;

[0062] (2) The steel pipe is quenched and heated in a progressive heating furnace. The heating temperature is 835°C and the holding time is 25 minutes. When cooling to 128°C, stop the cooling water, then step into the furnace for tempering and heating, the heating temperature is 615°C, and the tempering holding time is 59 minutes;

[0063] (3) After the steel pipe comes out of the tempering furnace, the seamless steel pipe 5 is placed on the two-way chain cooling bed through the conveying roller table 1 and the pulling device 2. The slope of the chain bed is 3°, the front is low and the back is high, and the forward chain 6 has 3, driven by a forward chain drive motor 3, 3 reverse chains 7, driven by a reverse chain drive ...

Embodiment 3

[0066] (1) The steel grade is ASTM A519 4130, the specification is 215.9*38.1mm seamless steel pipe 5, and after hot rolling, a six-roller straightening machine is used for roll straightening, and the bending degree of the seamless steel pipe 5 after straightening is 1.62mm / m;

[0067] (2) The steel pipe is quenched and heated in a progressive heating furnace. The heating temperature is 885°C and the holding time is 62 minutes. When cooling to 105°C, stop the cooling water, and then step into the furnace for tempering and heating. The heating temperature is 710°C, and the tempering holding time is 135 minutes;

[0068] (3) After the steel pipe comes out of the tempering furnace, the seamless steel pipe 5 is placed on the two-way chain cooling bed through the conveying roller table 1 and the pulling device 2. The slope of the chain bed is 3°, the front is low and the back is high, and the forward chain 6 has 3, driven by a forward chain drive motor 3, 3 reverse chains 7, driven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Straightness | aaaaa | aaaaa |

| Straightness | aaaaa | aaaaa |

| Straightness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com