Photochromic staining solution suitable for anodic oxidation technology and staining technique

A photochromic and anodic oxidation technology, which is applied in the field of dyeing liquid formulation and dyeing process, can solve the problems of inability to produce photochromic effect, and achieve the effect of wide application market, good performance and excellent gas barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

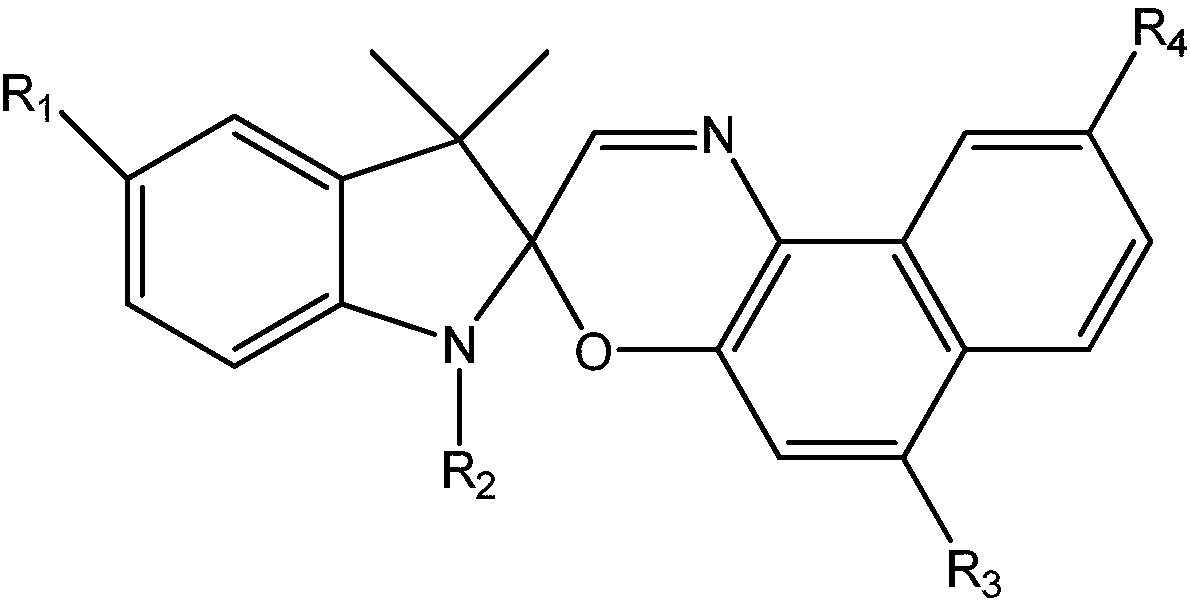

Image

Examples

Embodiment 1

[0109] A photochromic dye solution suitable for anodizing technology, comprising the following components by weight:

[0110]

[0111] The preparation method of described photochromic dyeing solution is:

[0112] Add novolac resin to propyl acetate according to parts by weight, stir and dissolve at 70°C to form a slightly viscous liquid, then add photochromic dye, light stabilizer and antioxidant in sequence according to parts by weight, and heat to 90-95°C , stirring and dissolving into a colored mixed liquid is the dyeing slurry.

[0113] The anodic oxidation dyeing process is as follows:

[0114] 1. Sample preprocessing:

[0115] In this embodiment, the aluminum sheet is selected as the sample, and the unsealed anodized aluminum sheet to be dyed is soaked in 10% sulfuric acid aqueous solution for several minutes. After taking it out, it is ultrasonically cleaned with distilled water and dried.

[0116] 2. Dyeing:

[0117] Take an appropriate amount of dyeing slurry i...

Embodiment 2

[0124] Select an aluminum sheet with the same oxide film thickness of 20 μ, use the technical scheme of Example 1, use the same temperature, time and assist ultrasonic dispersion dyeing, apply different voltages and times to seal the holes after dyeing, and use the same organic solvent to seal the holes. After cleaning, the experimental data obtained are as follows:

[0125]

[0126]

[0127] The above comparative test data show that the longer the sealing time, the better the sealing effect, and the higher the sealing voltage, the better the effect. The reason is: because the polymer material introduces the oxide film layer, which reduces the conductivity of the metal sample, the sealing voltage needs to be slightly higher, preferably 10-50% of the conventional process, and the use of a higher sealing voltage can shorten the Sealing time.

Embodiment 3

[0129] A photochromic dyeing solution suitable for anodic oxidation dyeing process, comprising the following components by weight:

[0130]

[0131] The preparation method of described photochromic dyeing solution is:

[0132] Add linear polyacrylic resin to butyl acetate according to parts by weight, stir and dissolve at 80°C to form a transparent liquid, then add photochromic dye, light stabilizer and antioxidant according to parts by weight, heat to 90-95°C, stir The mixed liquid that dissolves into color is the dyeing slurry.

[0133] The anodic oxidation dyeing process is as follows:

[0134] 1. Sample preprocessing:

[0135] The samples in this example are made of stainless steel sheets, and the unsealed anodized stainless steel sheets to be dyed, with different surface textures, are soaked in 5% sulfuric acid aqueous solution for several minutes, taken out, ultrasonically cleaned with distilled water, and dried;

[0136] 2. Dyeing:

[0137] Take an appropriate am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com