Fine-gauge single weft knitted fabric

A knitted fabric and high gauge technology, which is applied in the field of high gauge single-sided weft knitted fabrics and high-grade knitted underwear fabrics, can solve the problems of poor hand feeling of high-density fabrics, and increase the silky texture and drape of fabrics, soft hand feeling, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

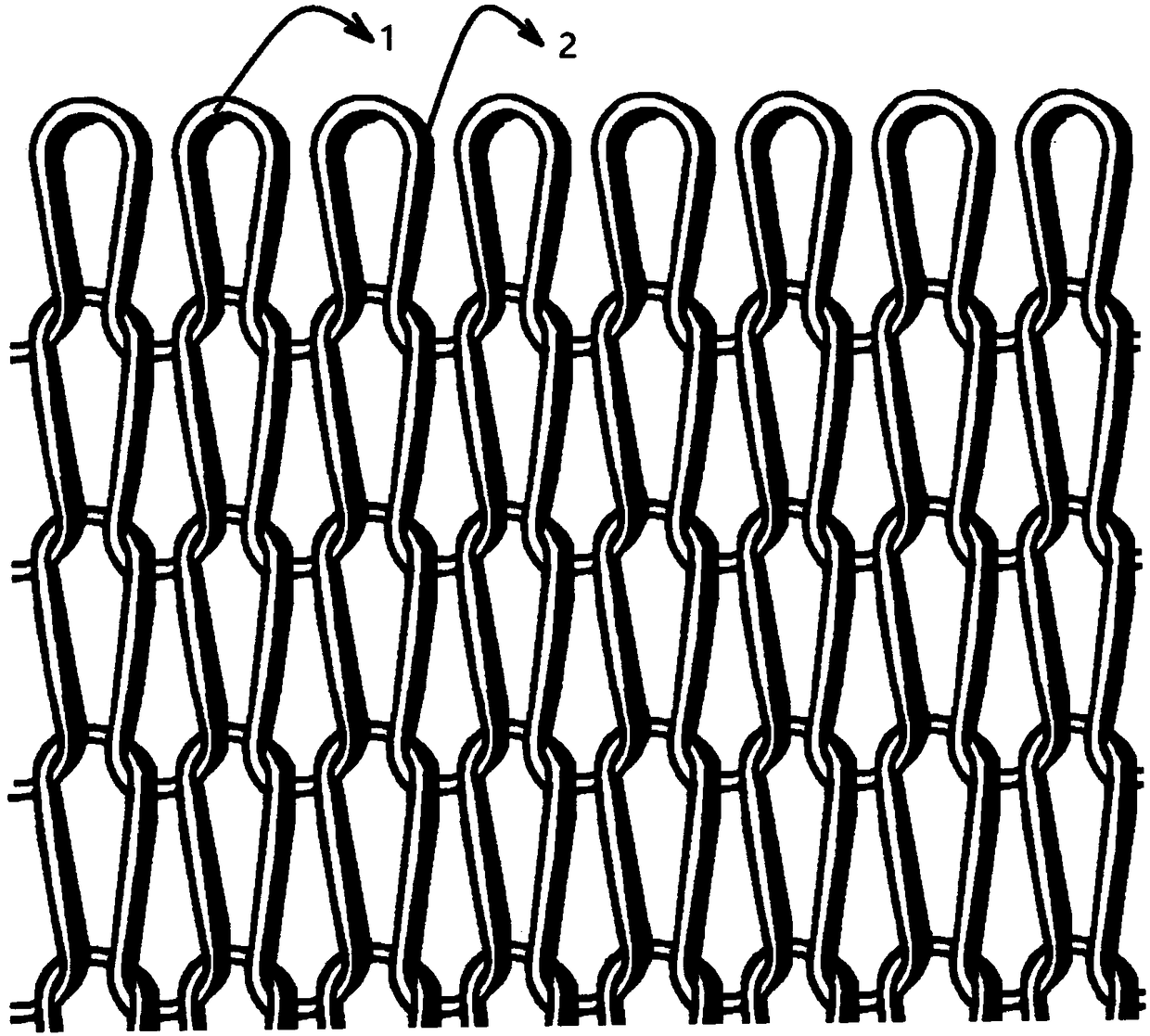

[0023] This embodiment provides a high gauge single weft knitted fabric, such as figure 1 As shown, including the fabric body, the fabric body is a fabric of weft flat stitch plating structure, with 120 S The long-staple cotton yarn is the face yarn 1, the 20D spandex is the ground yarn 2, and the warp and weft flat needle plating is woven into a rough fabric, and the rough fabric is sequentially subjected to width cutting, presetting, singeing, enzyme treatment, pretreatment, dyeing, and open width Finishing processes such as water rolling, soft drying, standing, soft tentering, calendering, inspection and rolling, etc., to make light blank fabrics.

[0024] The specific steps of the preparation method of the above-mentioned high gauge single weft knitted fabric are as follows:

[0025] 1): choose 120 S The long-staple cotton yarn is used as the face yarn, and the 20D spandex is used as the ground yarn, and is woven on a single-sided circular weft machine with a tube diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com