Plastic pipe gallery and plastic comprehensive pipe gallery system

A comprehensive pipe gallery and plastic technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of complex process, low production efficiency, long construction period, etc., and achieve simple process, high production efficiency, The effect of low production and construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] The plastic pipe gallery of this embodiment is applied to the laying of urban underground engineering pipelines.

[0078] Plastic pipe gallery, such as figure 1 As shown, it includes a positioning base pipe 1 with a ring-shaped cross-sectional shape. The material of the positioning base pipe 1 is high-strength and its modified and reinforced plastic, and the specific strength of the plastic is greater than 0.1N·m / kg.

[0079] The material of the positioning base pipe 1 in this embodiment adopts high-strength and modified-enhanced plastics. High-strength means that the specific strength of the plastic is greater than 0.1N·m / kg, and the plastic is modified and enhanced, which means adding modified plastics to the plastic. The specific strength of the modified reinforced plastic is also greater than 0.1 N m / kg, so as to ensure that the pipe gallery has high strength and can withstand the surrounding soil when it is applied. The pressure applied will not cause deformation ...

Embodiment 2

[0089] The plastic pipe gallery of this embodiment is applied to the laying of urban underground engineering pipelines.

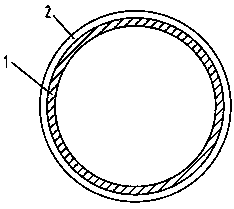

[0090] Plastic pipe gallery, such as figure 2 and image 3As shown, the plastic pipe gallery of this embodiment is basically the same as the plastic pipe gallery of Embodiment 1, the difference is that a plurality of annular reinforcing ribs 2 are arranged on the outer wall of the positioning base pipe 1, and a plurality of said annular reinforcing ribs 2 Arrange along the axial direction of the positioning base pipe 1, and strengthen the positioning base pipe 1 by arranging a ring-shaped reinforcing rib 2 on the outer wall of the positioning base pipe 1, so that the positioning base pipe 1 has a higher strength in the length direction , and, after arranging the annular reinforcing rib 2, when the plastic pipe gallery is installed in an underground tunnel, the annular reinforcing rib 2 can increase the frictional resistance between the pipe gallery and th...

Embodiment 3

[0093] Plastic pipe gallery, such as Figure 4 As shown, it includes a positioning base pipe 1 with a ring-shaped cross-sectional shape. The material of the positioning base pipe 1 is high-strength and its modified and reinforced plastic, and the specific strength of the plastic is greater than 0.1N·m / kg.

[0094] The outer wall of the positioning base pipe 1 in this embodiment is also sleeved with an outer wall pipe 3. The cross-sectional shape of the outer wall pipe 3 corresponds to the cross-sectional shape of the positioning base pipe 1. The cross-sections of the positioning base pipe 1 and the outer wall pipe 3 in this embodiment The shapes are all ring-shaped, and connecting ribs 4 are connected between the outer wall pipe 3 and the positioning base pipe 1 .

[0095] According to the technical solution of this embodiment, it is easy to think that the connecting ribs 4 can be arranged horizontally or vertically, so that the connecting ribs can only include horizontal conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com