Method for preventing and removing scale of non-strong alkali solution by rare-earth porcelain sand

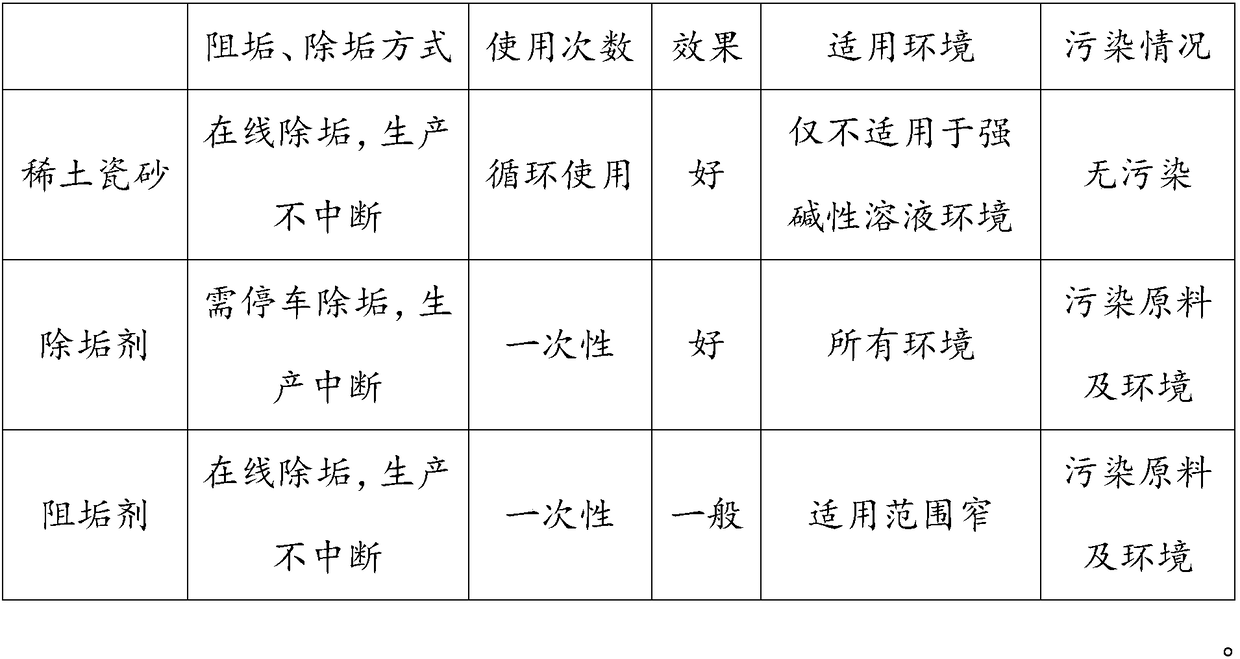

An alkaline solution, porcelain sand technology, applied in damage protection, heat exchange equipment, cleaning heat transfer devices, etc., can solve problems such as lack of descaling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

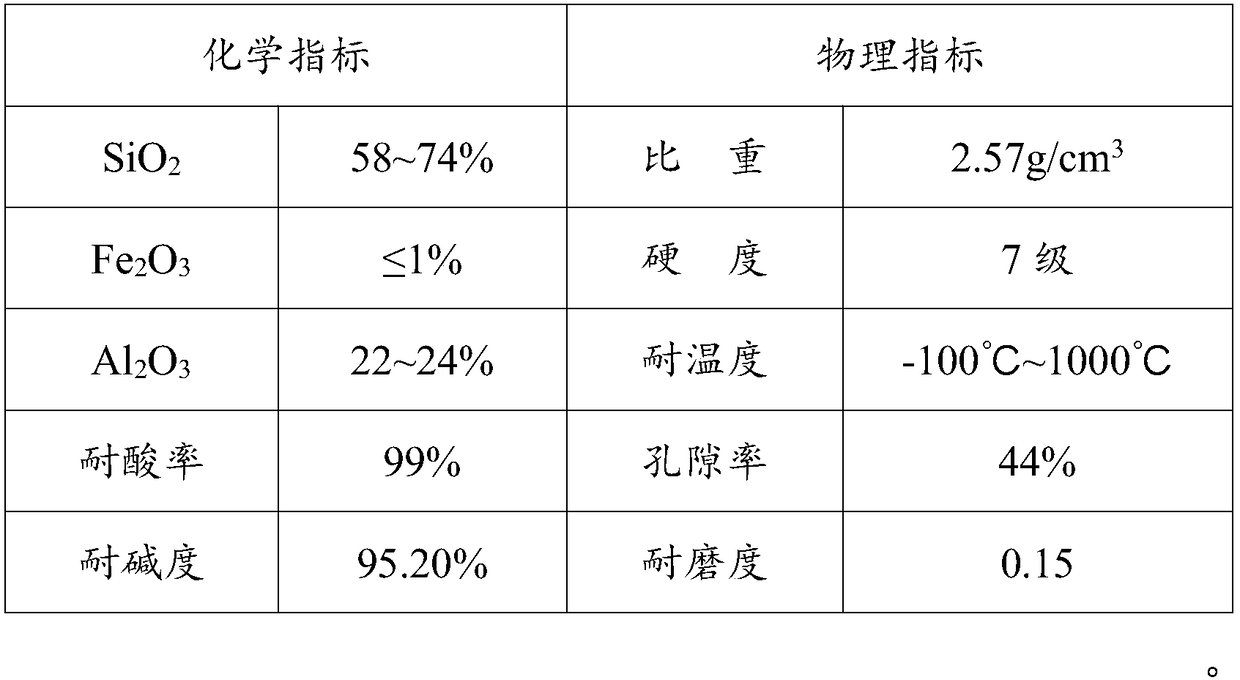

Method used

Image

Examples

Embodiment 1

[0018] Example 1, when the volume ratio of rare earth porcelain sand was 5%, and the volume ratio of aqueous sodium chloride solution was 95%, after 24 hours, the scaling rate was 5g / (m 2 h), after 48 hours, the fouling rate was 3g / (m 2 h), after 96 hours, the fouling rate was 1.6g / (m 2 h).

Embodiment 2

[0019] Example 2, when the volume ratio of rare earth porcelain sand was 8%, and the volume ratio of sodium chloride aqueous solution was 92%, after 24 hours, the scaling rate was 4g / (m 2 h), after 48 hours, the fouling rate was 2.2g / (m 2 h), after 96 hours, the fouling rate was 1.2g / (m 2 h).

Embodiment 3

[0020] Example 3, when the volume ratio of rare earth porcelain sand was 10%, and the volume ratio of sodium chloride aqueous solution was 90%, after 24 hours, the scaling rate was 3.8g / (m 2 h), after 48 hours, the fouling rate was 2.1g / (m 2 h), after 96 hours, the fouling rate was 1.1g / (m 2 h).

[0021] The solution to be exchanged is sodium sulfate aqueous solution as an example, and the anti-scaling and descaling effects of rare earth porcelain sand are as shown in Examples 4-6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com