Telescopic multimeter pen head

A multimeter and telescopic technology, which is applied in the direction of instruments, measuring devices, measuring electricity, etc., can solve the problems of unsafe operation of equipment, short relative distance between terminals, electric shock of testing personnel, etc., to achieve free control of position and distance, and strengthen reliability performance, accuracy, and increased detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

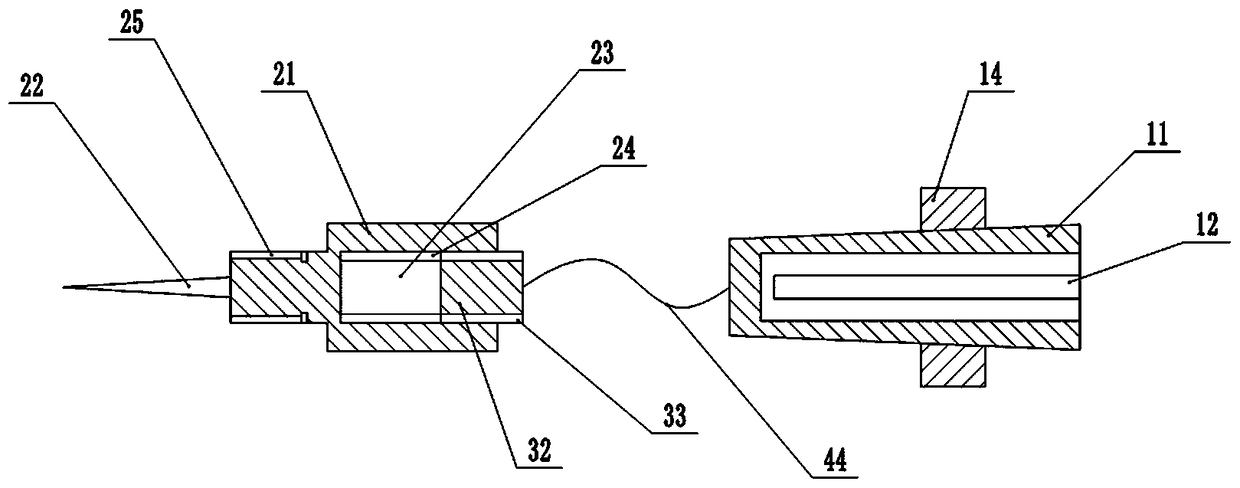

[0034] Combine below Figure 1-5 To further describe the present invention.

[0035] The present invention adopts following technical scheme:

[0036] A retractable multimeter lead, including a connection part, a detection head and a connection line;

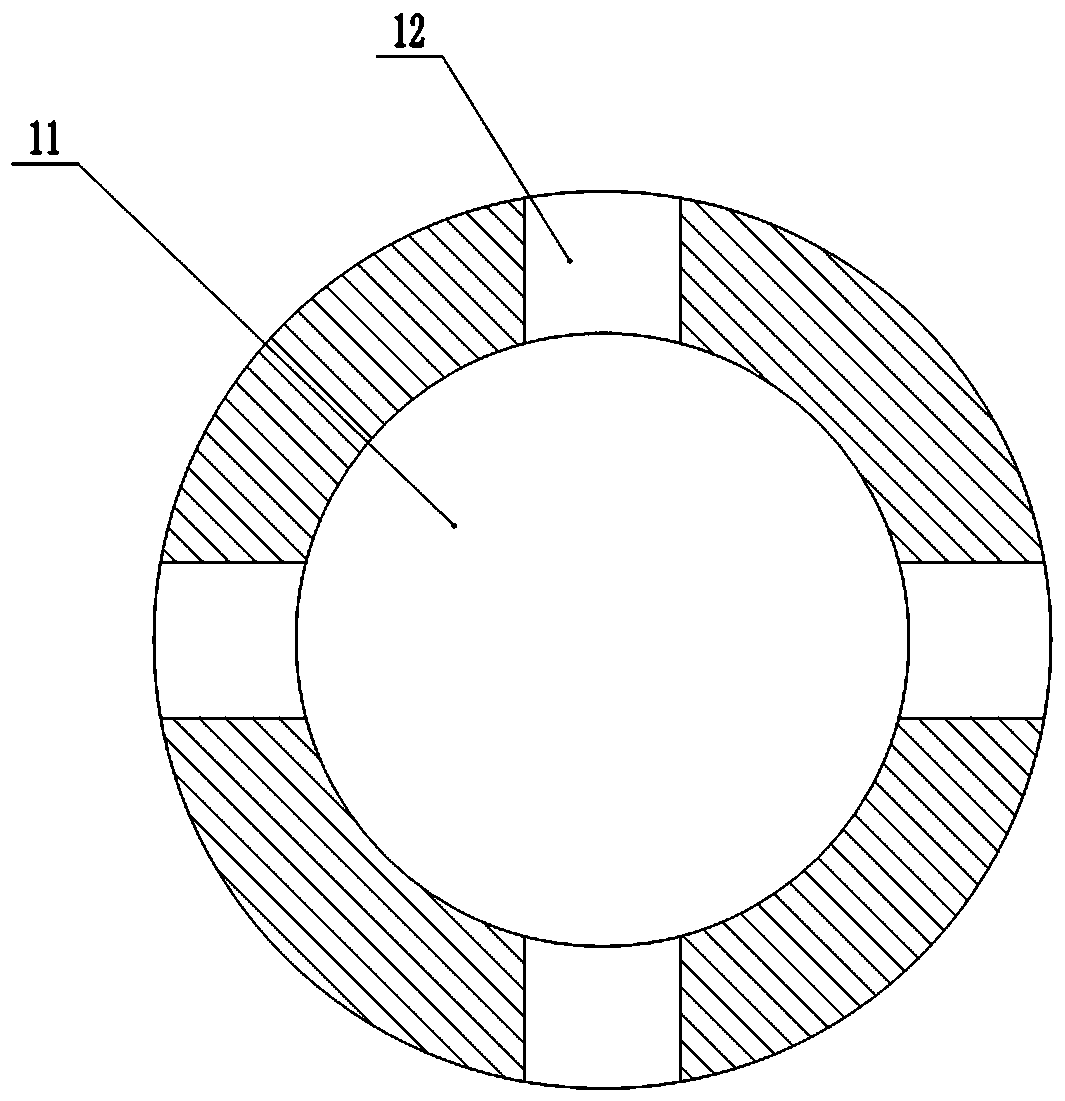

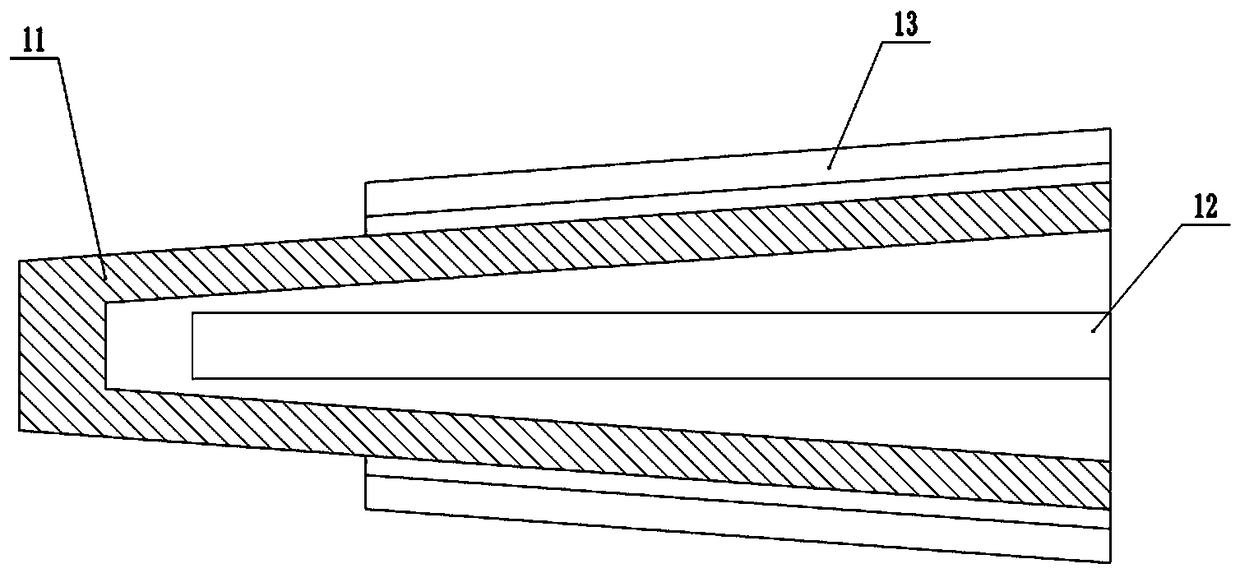

[0037] The connecting part comprises a connecting pipe 11, long grooves 12 evenly distributed on the outer wall of the connecting pipe 11, threads 13 arranged on the outer wall of the connecting pipe 11 and fastening nuts 14 threadedly connected with the connecting pipe 11;

[0038] One end of the long groove 12 is an open end, and the other end is a closed end;

[0039] One end of the connecting pipe 11 is a closed end, and the other end is an open end;

[0040] The detection head includes a detection cylinder 21, a probe 22 fixed at one end of the detection cylinder 21, a hole 23 at the other end of the detection cylinder 21, a connecting thread A24 on the inner wall of the hole 23 and a screw thread on the outer wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com