An automatic roasting device for betel nut tobacco and fruit

A baking device and betel nut technology, applied in application, food science, food processing and other directions, can solve the problems of inconvenient operation, low smoking efficiency, safety accidents, etc., and achieve convenient operation, reduce air pollution, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to facilitate the understanding of the present invention, the present invention will be described more fully and in detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

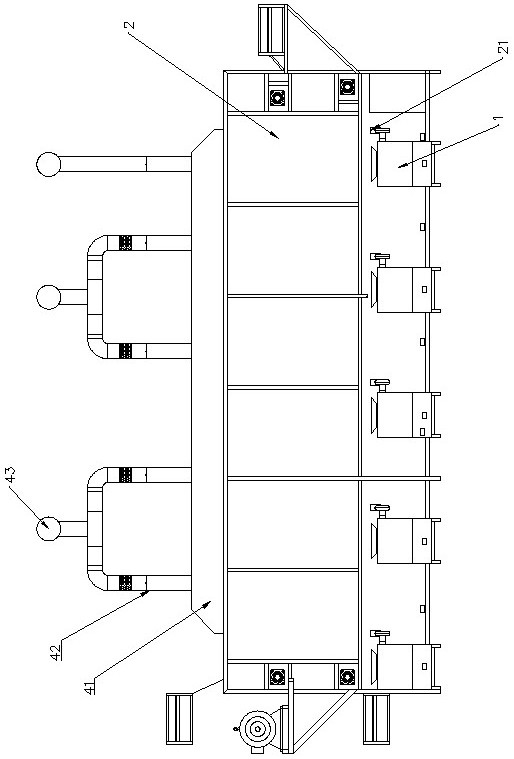

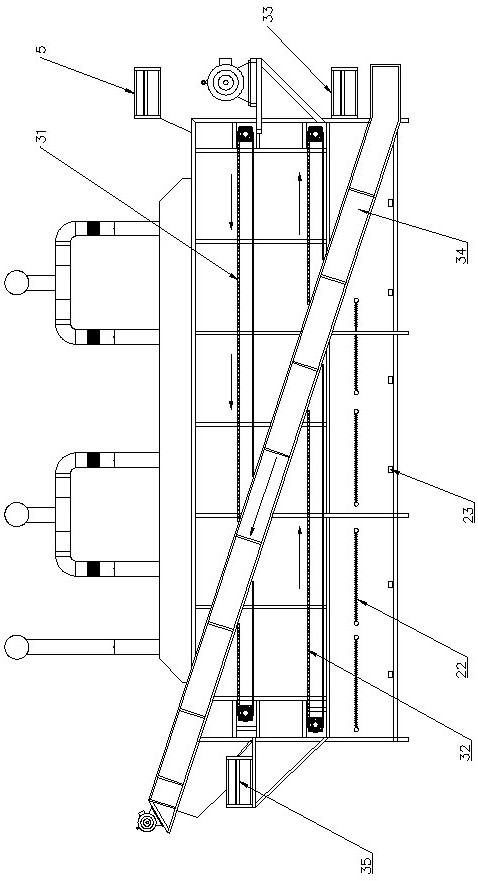

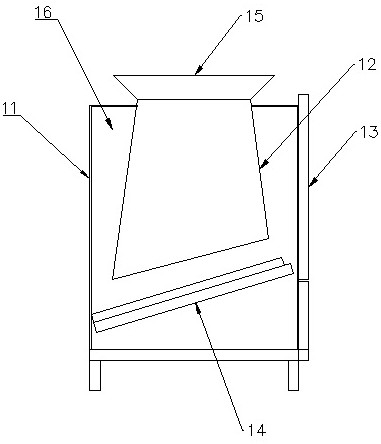

[0028] like figure 1 , figure 2 As shown, a kind of betel nut automatic roasting device of this embodiment includes a fume generating furnace 1, a baking furnace 2, an automatic furnace turning mechanism, and a tail smoke processing device. The fume generating furnace 1 is used to produce smoke Smoke; the baking furnace 2 includes a furnace body 21, a smoke inlet is provided under the furnace body, and a smoke inlet pipe 24 is provided at the smoke inlet to communicate with the fume generator 1. An auxiliary heater 22 is also provided below the furnace body, and an air supply port 23 is respectively provided at the bottom of both sides of the furnace body 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com