Crusher

A pulverizer and casing technology, which is applied in the field of electromechanical devices, can solve the problems of low heat dissipation effect and high noise, and achieve the effect of low noise, broad prospects and high heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

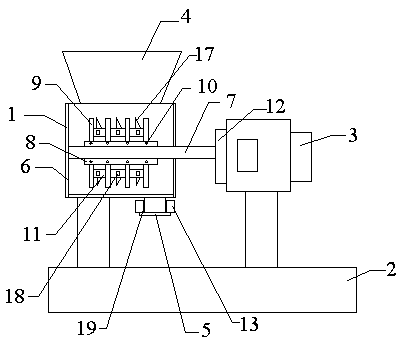

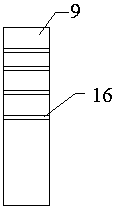

[0016] figure 1 Show the specific embodiment of the present invention: a kind of pulverizer, comprise casing 1, base 2, motor 3 and crushing structure, described casing 1 and motor 3 are arranged on the base 2, the upper and lower ends of described casing 1 A feed port 4 and a discharge port 5 are provided, a wear-resistant liner 6 is provided on the inner wall of the casing 1, and the crushing structure includes a main shaft 7, a hammer frame 8 and a hammer 9, and the hammer frame 8 are set on the upper and lower sides of the main shaft 7, the hammer 9 is set on the hammer frame 8 through screws 10, spacers 11 are arranged between the hammers 9, and the motor 3 and the main shaft 7 are connected through a coupling 12, and vibration motors 13 are arranged on both sides of the discharge port 5.

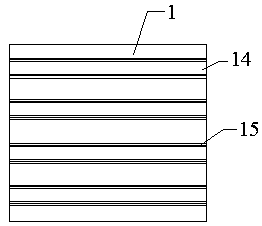

[0017] In addition, if figure 2 and 3 As shown, the outer wall of the casing 1 is provided with a heat dissipation groove 14, the heat dissipation groove 14 is provided with a heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com