Waste vehicle double-roller rolling device

A double-drum, car technology, applied in the direction of solid waste removal, etc., can solve the problem of low efficiency of scrapped cars, achieve the effect of reducing manual operations, saving labor costs, and reducing uncontrollability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

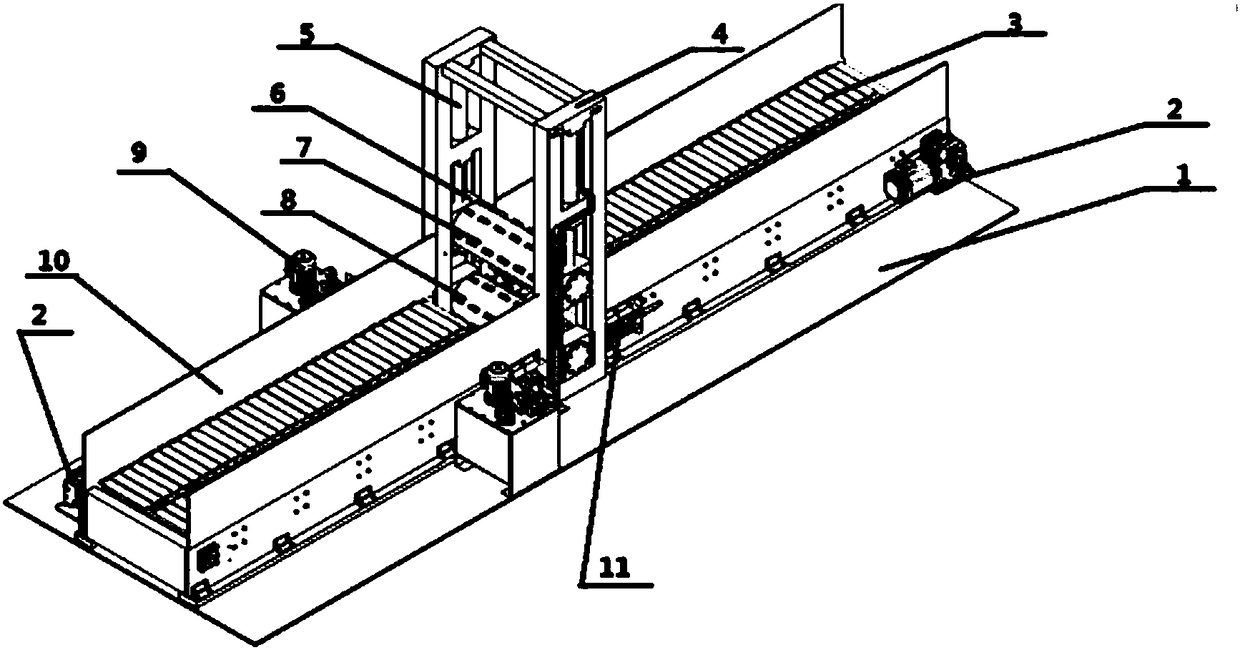

[0018] A double-roller rolling device for waste automobiles, comprising a base plate 1, a gantry frame 4, and a conveyor belt 3, a data processing module, a data analysis module, and a data transmission module, the conveyor belt 3 and the gantry frame 4 are all arranged on the base plate 1, and the The gantry 4 is provided with a hydraulic jack 5 and a rolling bearing 6. The rolling bearing 6 is embedded in the gantry 4 through the peripheral frame and can move up and down along the inner guide rail of the gantry 4. The upper end of the hydraulic jack 5 is fixed on the top of the gantry 4, and the lower end is connected to the The peripheral frame connection of the rolling bearing 6,

[0019] Directly below the gantry 4 is provided with a driven roller 7 and a driving roller 8 placed up and down. The position of the driving roller 8 is slightly higher than the conveyor belt 3 , and the driving roller 8 is connected to a driving motor 11 .

[0020] The bottom plate 1 and the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com