Pyrolyzing device for repairing contaminated soil

A technology for polluted soil and soil heat, applied in the field of pyrolysis devices, can solve the problems of natural normal dysfunction of soil, blank research on remediation equipment, and destruction of natural dynamic balance, etc., to achieve soil improvement and restoration, improvement and restoration of air pollution, reduction Effects of air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

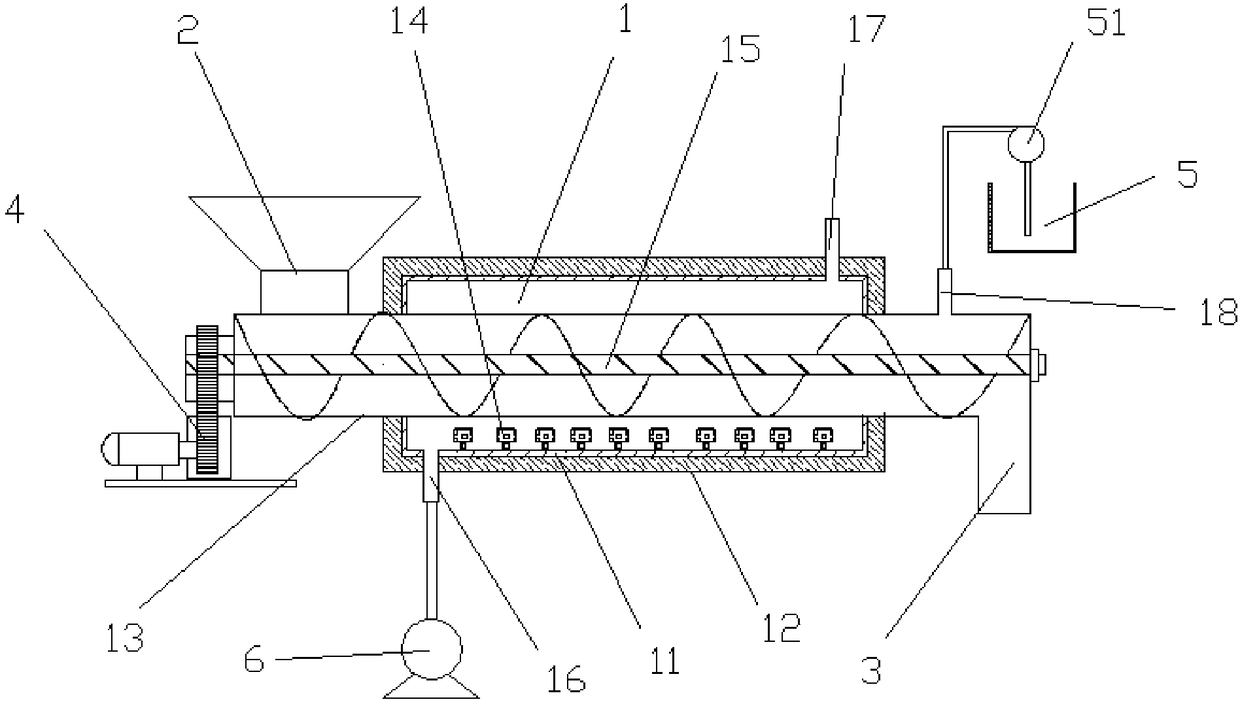

[0021] Please refer to figure 1 As shown, a pyrolysis device for repairing contaminated soil includes a feed device 2 , a discharge device 3 , a soil pyrolysis device 1 , a transmission device 4 , a pyrolysis gas absorption and treatment device 5 and a gas supply device 6 .

[0022] The soil pyrolysis device 1 includes a heating furnace body 11 with a heating chamber inside and a pyrolysis cylinder 13 .

[0023] An opening communicating with the heating chamber is provided at the center of the left and right ends of the heating furnace body 11 . The top end of the heating furnace body 11 is provided with an air outlet 17 , and the bottom end of the heating furnace body 11 opposite to the air outlet 17 is provided with an air inlet 16 . The heating furnace body 11 is provided with a furnace body insulation layer 12 , and the bottom of the heating furnace body 11 is provided with an electric heating element 14 .

[0024] The pyrolysis cylinder 13 is arranged in the heating fur...

Embodiment 2

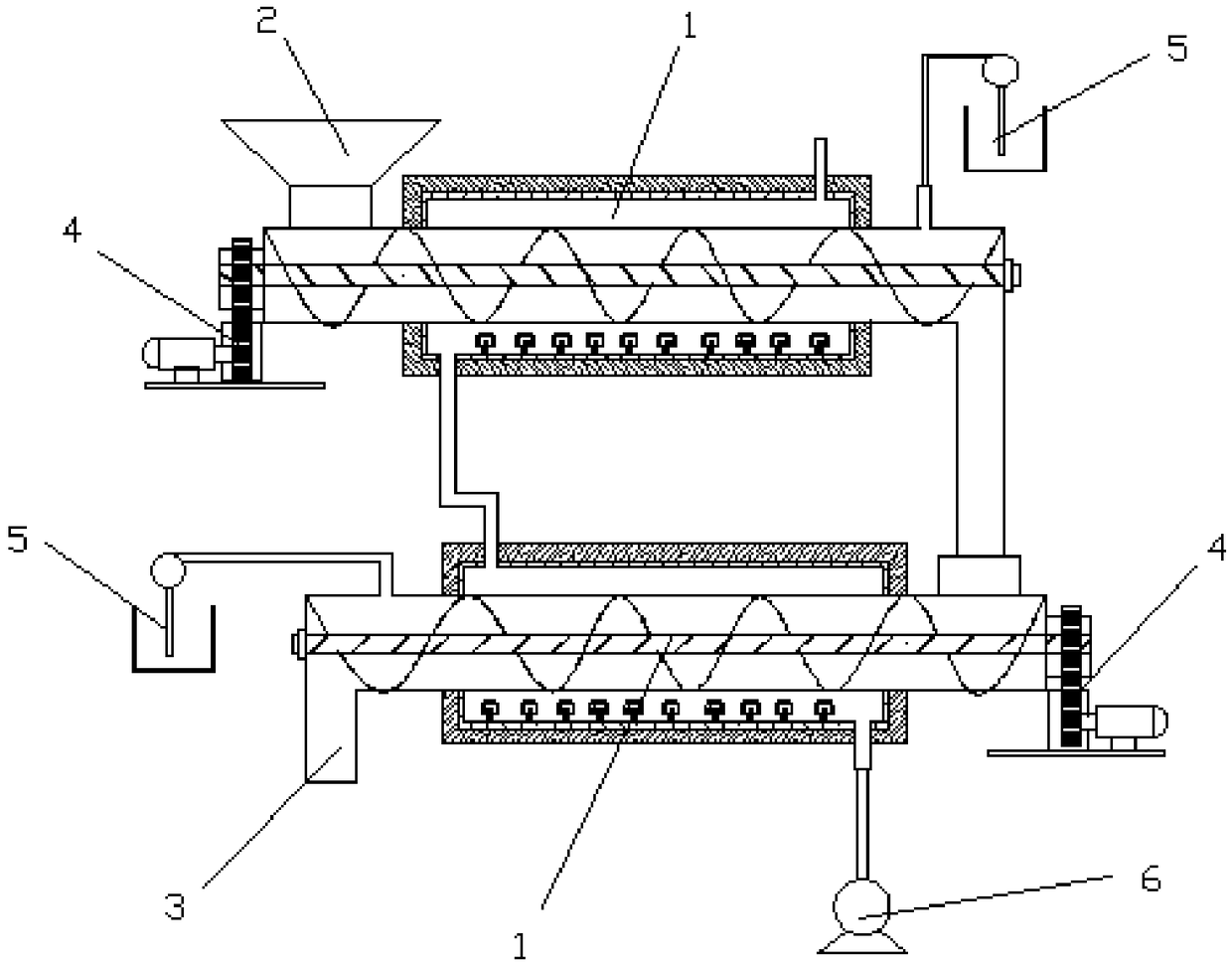

[0030] Please refer to figure 2 As shown, when the moisture content in the soil is high, the energy consumption of soil pyrolysis restoration will increase. In order to ensure a good pyrolysis effect, the soil pyrolysis device 1 described in Example 1 is set to two stages. Specifically: connect the discharge device 3 of the primary soil pyrolysis device 1 with the feed device 2 of the secondary soil pyrolysis device 1; connect the pyrolysis gas outlet 1817 of the primary soil pyrolysis device 1 with the secondary soil After the pyrolysis gas outlet 1817 of the pyrolysis device 1 is connected, it is collected in a connecting pipe, and the connecting pipe is connected to the suction fan; Air outlet connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com