Automatic welding machine for welded elbows

An automatic welding machine and elbow technology, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of unstable weld quality, high work intensity, and low welding efficiency, and achieve low requirements for welding professional skills , The appearance of the weld seam is beautiful, the welding quality is high and the effect is excellent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

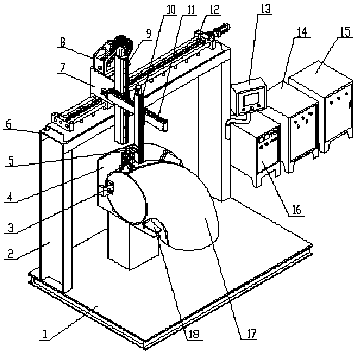

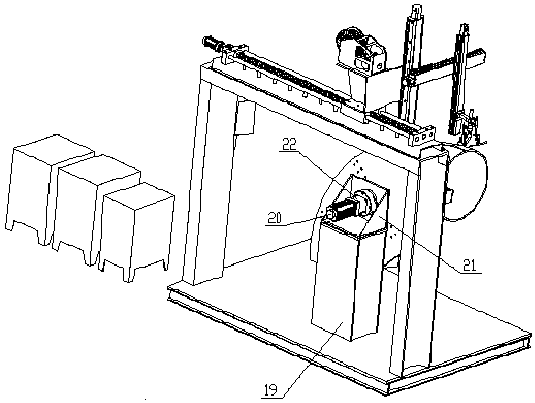

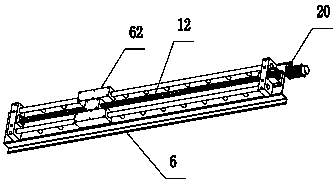

[0026] The present invention will be further described below in conjunction with the accompanying drawings: As shown in the figure, the butt welding elbow automatic welding machine includes a corresponding support 2 and a support 19, and the support is provided with a drive driven by a first power source 20 to move along the horizontal direction. A rectilinearly moving traction seat 8, the traction seat is provided with a lifting torch 5, the support is provided with a rotating disk 4 driven by the second power source, and a workpiece 17 is installed on the rotating disk. The rotating disk includes a first position where the top outer wall of the workpiece is set corresponding to the welding torch, and a second position where the bottom outer wall of the workpiece is set corresponding to the welding torch after rotation. When in use, the welding torch is moved back and forth by the traction seat, and the welding torch itself is raised and lowered to adjust the welding position....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com