A bottom device for a cement silo

A technology of cement storage and control circuit, applied in cement mixing device, control device, clay preparation device, etc., can solve the problems of increasing cement unit cost, reducing cement agglomeration effect, and high power consumption of Roots blower, so as to strengthen the prevention and control. Hardening effect, reduction of cement unit cost, reduction of social disputes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

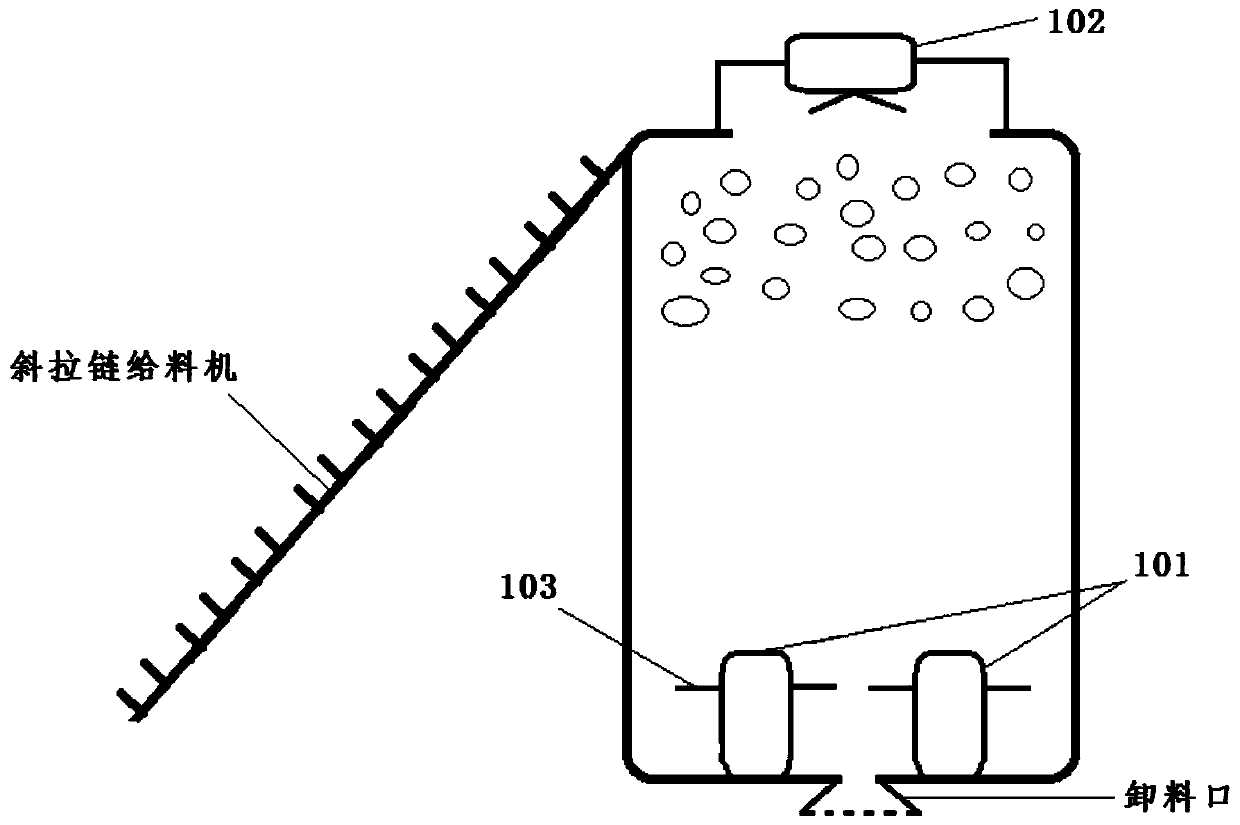

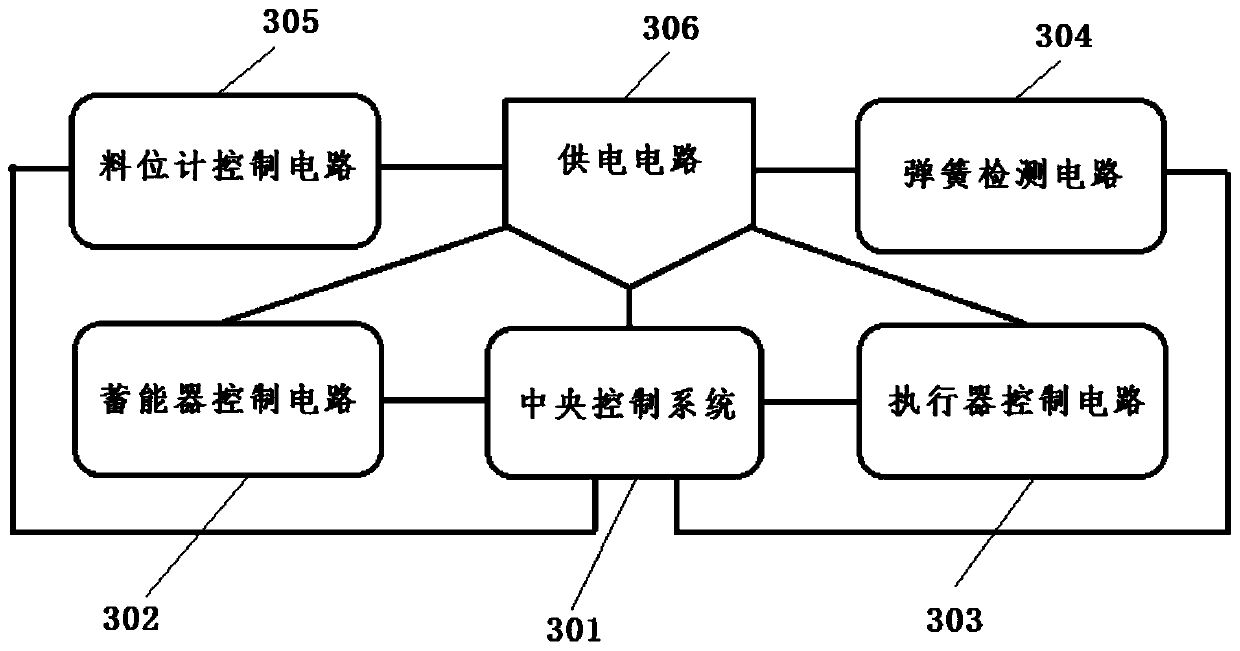

[0038] Depend on figure 1 As shown, a bottom device of a cement silo includes: a bottom unit 101, a material level unit 102, and a control unit; it also includes multiple sets of high-pressure springs;

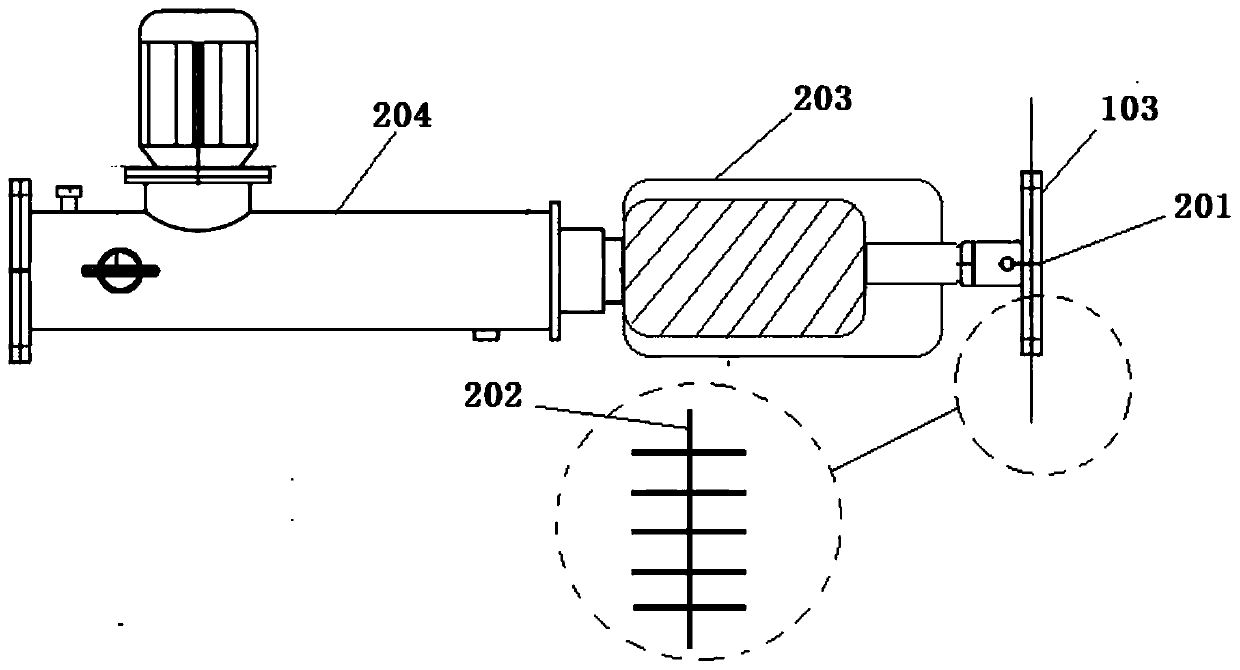

[0039] Further, the base unit 101 includes: a support surface structure 201, an accumulator 203, and an electro-hydraulic push rod 204. Around the support surface structure 201, comb structures 202 are symmetrically arranged; the support surface structure 201 The lower surface is fixedly arranged at one end of the accumulator 203, and the other end of the accumulator 203 is connected to the telescopic part of the electro-hydraulic push rod 204, and the tail of the electro-hydraulic push rod 204 is fixedly arranged on the cement library bottom;

[0040] As an example, the supporting surface structure 201 is used to lift the cement powder sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com