Device for long-term sampling and filament collecting under various working conditions

A long-term, working-condition technology, applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of many interference factors in the sampling process, difficult to reproduce abnormal working conditions, and large number of tows, etc., to achieve The effect of reducing the workload of personnel, reducing defective products, and avoiding additional interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

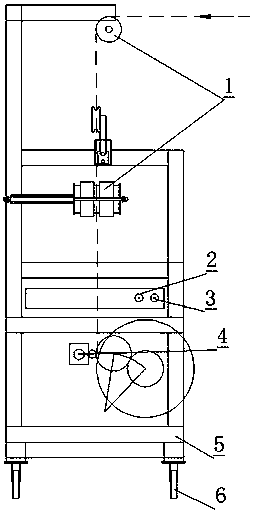

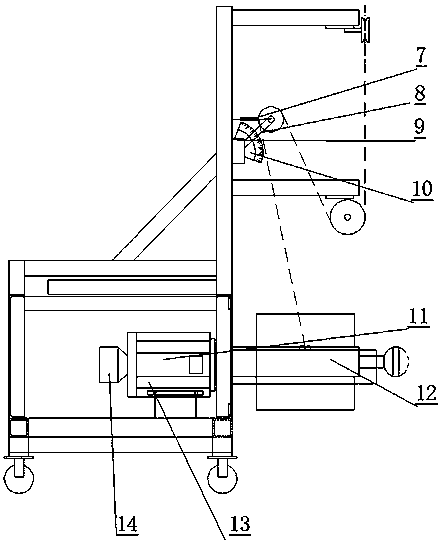

[0023] like figure 1 and figure 2 As shown, this embodiment is a device for long-term sampling and collection under various working conditions, including a godet 1, a speed adjustment mechanism 2, a power switch 3, a spindle pressure adjustment mechanism 4, a base 5, and a wheel 6. Automatic tension adjustment mechanism with scale 7, swing arm 8, broken wire contact alarm, 9, detachable tension spring 10, wire collection style adjustment mechanism 11, uniform wire laying mechanism 12, total motor 13 and power transmission system 14, The wheels 6 are arranged below the base 5, the wire-receiving style adjustment mechanism 11, the uniform wire laying mechanism 12, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com