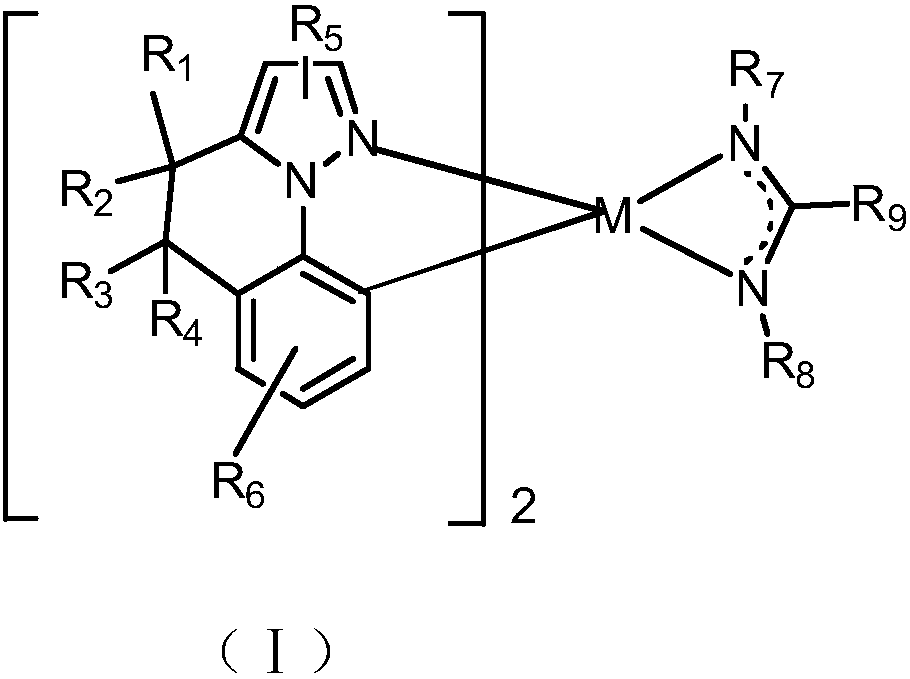

Metal complex and organic light emitting device thereof

A technology of organic light-emitting devices and metal complexes, which is applied in the fields of light-emitting materials, organic chemistry, and electric solid-state devices, and can solve problems such as low luminous efficiency, poor thermal stability of phosphorescent materials, and short lifespan.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

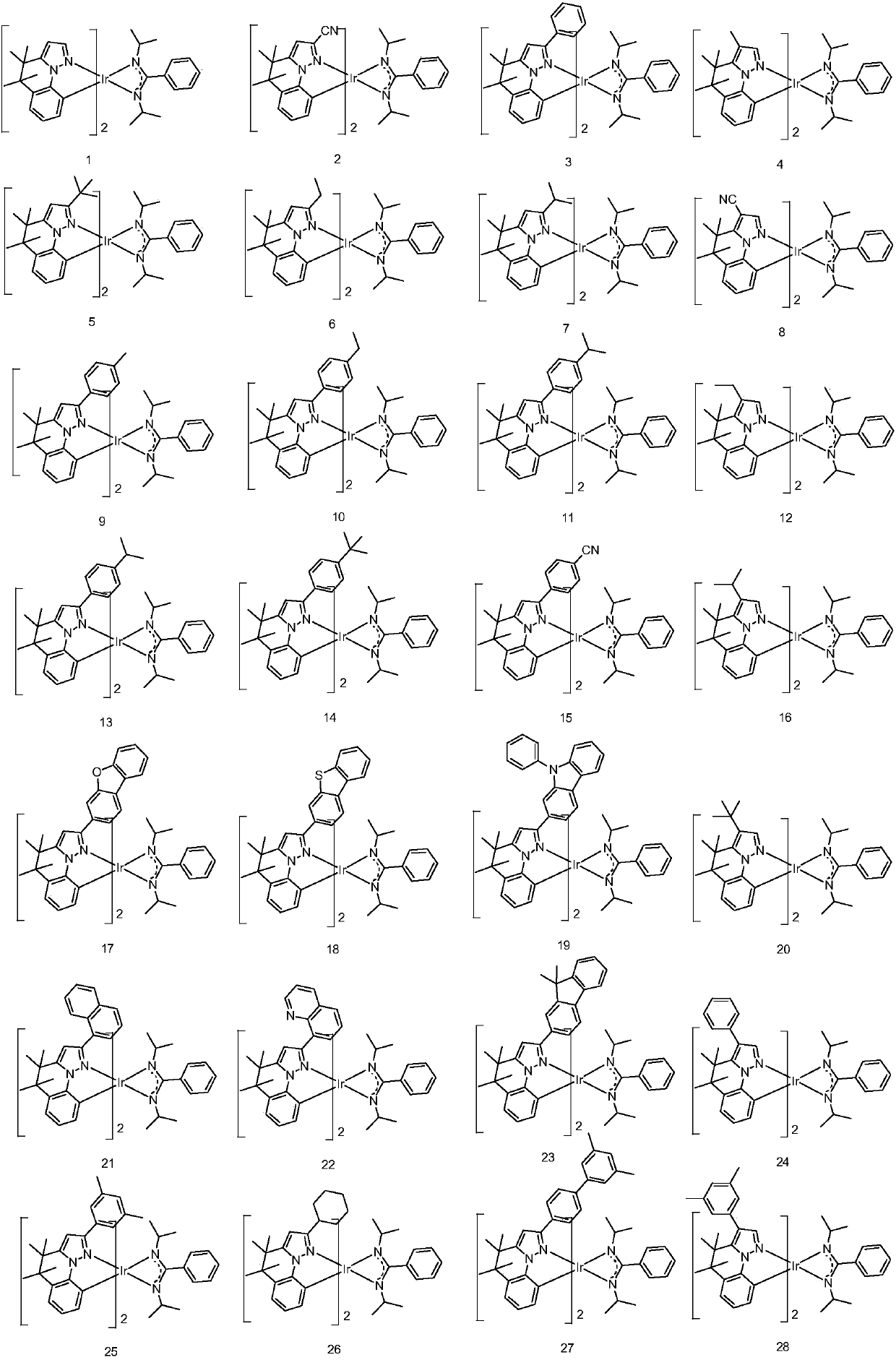

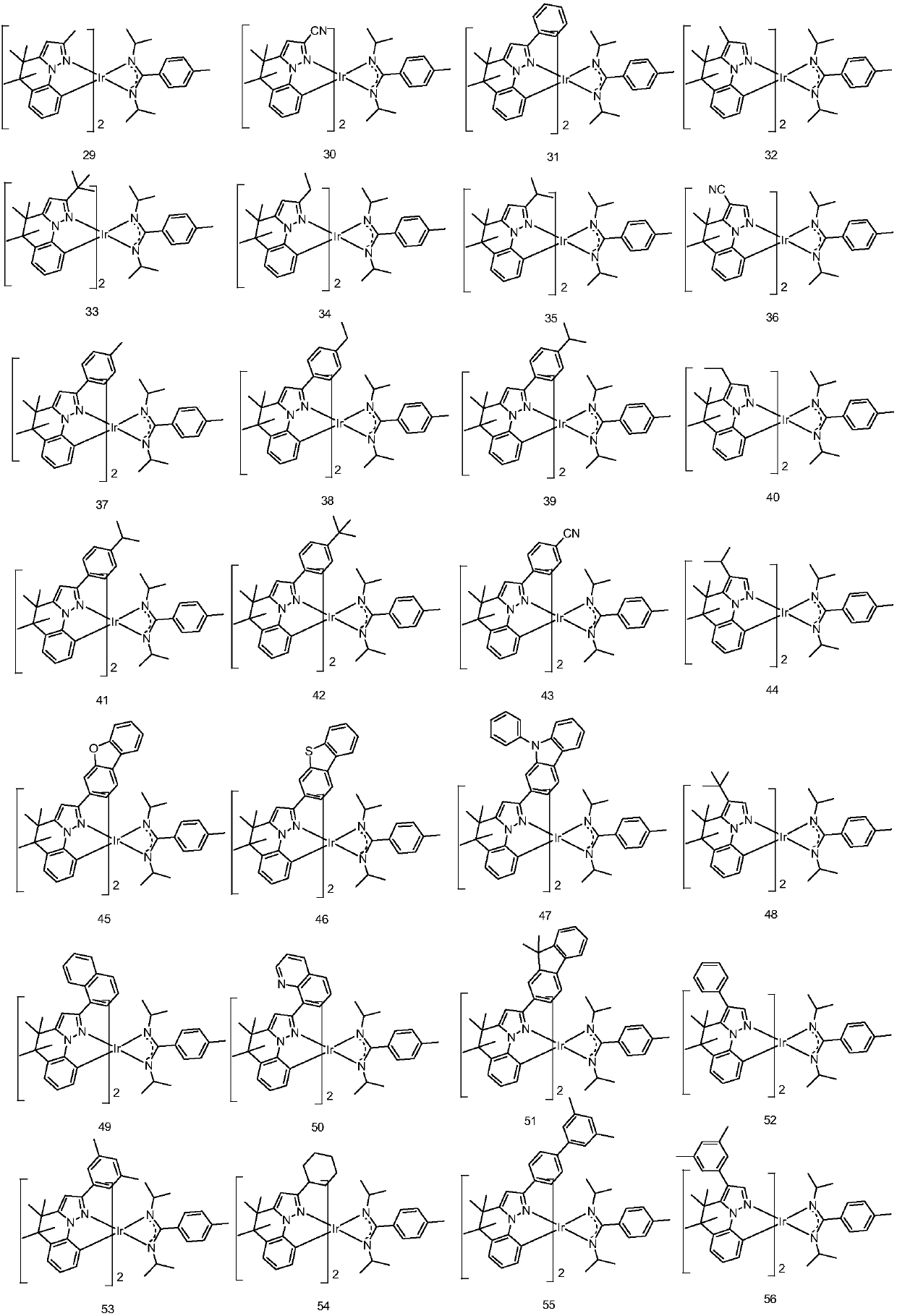

Examples

Embodiment 1

[0060] Embodiment 1: the preparation of compound 1

[0061]

[0062] Preparation of 1-3

[0063] 1-1 (7.354g, 36.9mmol) was dissolved in THF (250ml) solution and cooled in an ice-water bath. Trifluoromethanesulfonic acid (3.58ml, 40.6mmol) was added and the resulting mixture was stirred cooled for 30min, then allowed to warm to room temperature and stirred overnight. Water, brine and saturated sodium carbonate were added to the mixture and the resulting mixture was extracted several times with EtOAc. The combined organics were separated and washed with brine, dried and reduced vacuum to form 15.8 g of an orange oil which solidified. The mixture was subjected to column chromatography to obtain 1-3 7.68 g, 85% yield.

[0064] Preparation of 1-4

[0065] 1-3 (5.57g, 22.80mmol) was dissolved in THF (150ml) solution in isopropanol / CO 2 Cool in a bath and add a solution of methyllithium in ether (1.6M, 57.0ml, 91mmol) via syringe. The reaction mixture was stirred and cooled...

Embodiment 2

[0071] Embodiment 2: the preparation of compound 8

[0072] 1-3 in Example 1 was replaced by equimolar 8-3, and the other steps were the same as in Example 1 to obtain the target compound 8.

[0073]

[0074] Mass Spectrum m / z: 897.18 (calculated: 897.19). Theoretical element content (%)C 45 h 52 IrN 8 : C, 60.24; H, 5.84; Ir, 21.42; N, 12.49 Measured element content (%): C, 60.25; H, 5.85; Ir, 21.43; N, 12.48. The above results confirmed that the obtained product was the target product.

Embodiment 3

[0075] Embodiment 3: the preparation of compound 23

[0076]1-3 in Example 1 was replaced by equimolar 23-3, and the other steps were the same as in Example 1 to obtain the target compound 23.

[0077]

[0078] Mass Spectrum m / z: 862.24 (calculated: 862.25). Theoretical element content (%)C 46 h 61 IrN 4 : C, 64.08; H, 7.13; Ir, 22.29; N, 6.50 The measured element content (%): C, 64.09; H, 7.12; Ir, 22.28; N, 6.51. The above results confirmed that the obtained product was the target product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com