Steel with tensile strength being of 680MPa grade and used for large transportable pressure vessel and production method

A technology for tensile strength and pressure vessels, which is applied to the steel and production of large-scale mobile pressure vessels with a tensile strength of 680MPa, high-strength pressure vessel steel and its production fields, and can solve the problem of low strength levels and restrictions on domestic liquefied gas vehicles Larger tanker and other issues, to achieve the effect of reducing the weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention is described in detail below:

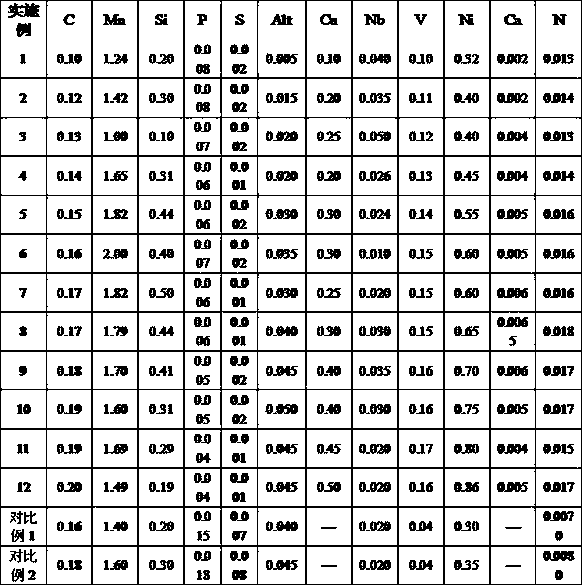

[0045] Table 1 is the chemical composition list of each embodiment of the present invention and comparative example;

[0046] Table 2 is the smelting and rolling process parameter list of each embodiment of the present invention and comparative examples;

[0047] Table 3 is the heat treatment process parameter list of each embodiment of the present invention and comparative example;

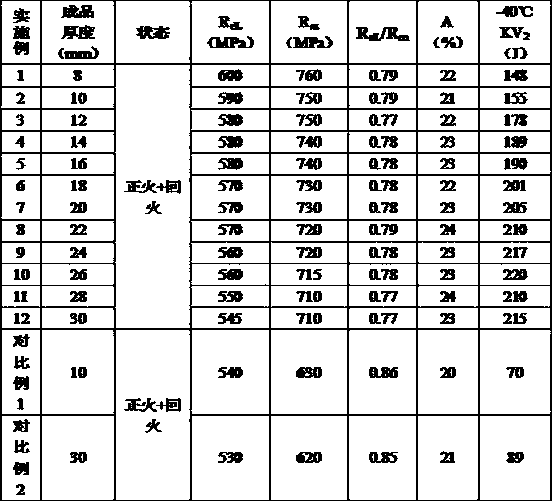

[0048] Table 4 is the mechanical test result of each embodiment of the present invention and comparative example;

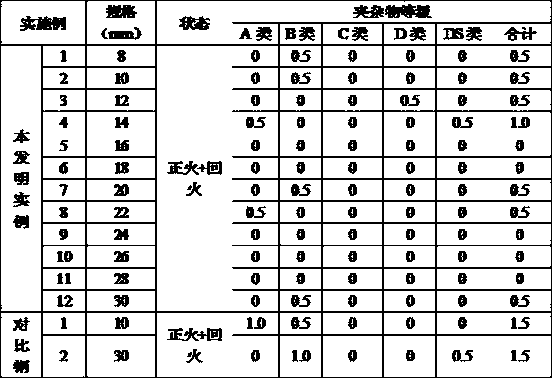

[0049] Table 5 shows the inclusion inspection results of the various embodiments and comparative examples of the present invention.

[0050] Each implementation case of the present invention all produces according to the following steps:

[0051] 1) Conventional hot metal pretreatment and converter smelting;

[0052] 2) RH vacuum treatment is carried out after refining outside the LF furnace, and VN alloy is added in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com