Manufacturing method for touch screen with antibacterial layer

A manufacturing method and touch screen technology, which are applied in the input/output process of data processing, heating inorganic powder coating, instruments, etc., can solve the problems of high labor and material resources, damage, etc., and achieve improved safety, strong antibacterial ability, and manufacturing. The effect of the method is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

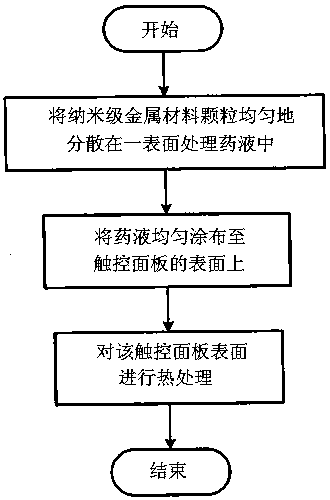

[0025] Embodiment 1: a kind of manufacturing method with antibacterial layer touch screen, its preparation steps are:

[0026] (1) Perform anti-glare treatment on a touch screen with glass material as the panel substrate: first, disperse nano-silver particles with a particle size of 1nm-100nm in the form of 30KHz ultrasonic vibration in the alcohol In the solvent; then mix an anti-glare surface treatment liquid composed of silicate (ester) compound and alcohol solvent into the dispersion, stir it for more than 10 minutes to make the two evenly mixed, and adjust the mixing The pH value of the solution is acidic, and the concentration of the nano-silver particles is maintained at 20-500 ppm.

[0027] (2) Spray the mixed solution evenly on the surface of the touch screen cover plate by spraying, and then perform heat treatment on the surface. The heat treatment temperature is 180° C. and the heat treatment time is 45 minutes.

[0028] (3) After the solvent in the composition on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com