Tool fixture for large-size sapphire single crystal

A sapphire and large-size technology, which is applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of difficult crystal extraction, collision between crystal and crucible, dark cracks, etc., achieve good fastening effect, avoid scratches, easy-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in detail below in conjunction with accompanying drawing:

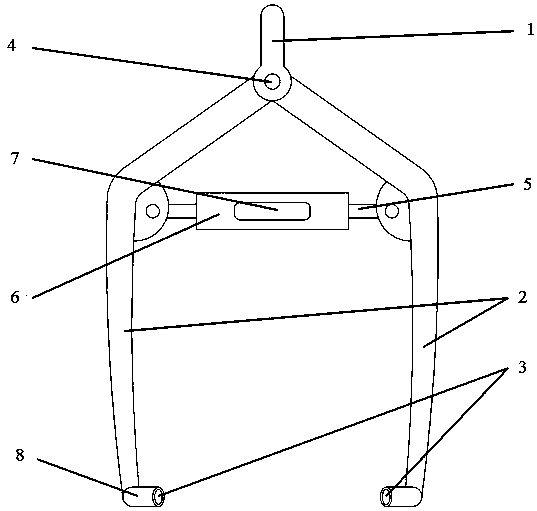

[0017] combine figure 1 , The overall structure of this embodiment is composed of a suspension ring 1, two "half-door-shaped" clamping arm structures 2, a bidirectional thread structure for opening or tightening the clamping arms, and a clamping chuck structure 3 for clamping. The lifting ring structure is fixed at the joint of the two "half-gate" clamping arm structures through lifting ring bolts 4; the upper parts of the two "half gate-shaped" clamping arm structures are connected by lifting ring bolts to ensure that the angle between the two clamping arms can be freely Adjustment, the lower part is welded on the chuck used for clamping; the two-way thread structure is composed of two bolts 5 and a cylindrical nut 6, the bolts are respectively connected at the corners of the jig arm, and the cylindrical nuts are screwed on the bolts in the same direction On the top, a recta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com