A method for preparing waste paper reinforcing agent from agricultural straw

A technology of reinforcing agent and straw, applied in pulp beating/refining method, papermaking, textiles and papermaking, etc., can solve the problems of resource waste and ineffective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

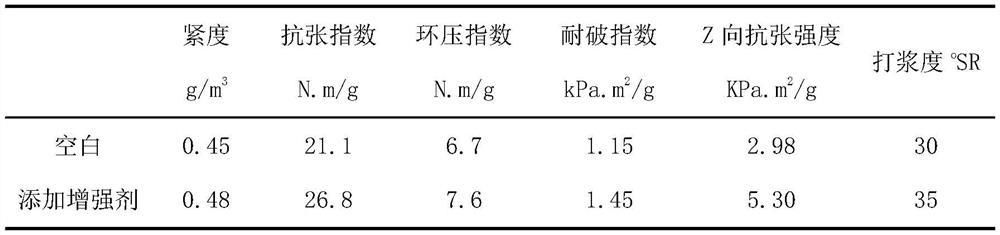

Embodiment 1

[0028] Cut the air-dried corn stalks into 2-3cm pieces, and process them in a rotary cooker with a solid-to-liquid ratio of 1:5, a maximum temperature of 175°C, and a holding time of 30 minutes. The processed raw materials are separated from solids and liquids and washed clean. Then, the treated raw material is mechanically treated with a disc refiner, and the refining concentration is 25%, so as to obtain high-yield pulp of corn stalks. Sieve with a 100-mesh sieve at a concentration of 1%, and the part that passes through the sieve is the parenchyma cell component. A high-pressure homogenizer was used to process the parenchyma cell suspension with a concentration of 1% under a pressure of 30 MPa for 30 minutes to obtain high-pressure homogenized modified parenchyma cells. The raw material of waste paper pulp is domestic old corrugated box (OCC). The modified parenchyma cells are mixed with waste paper pulp. The amount of parenchyma cells is 5% (mass ratio, relative to dry was...

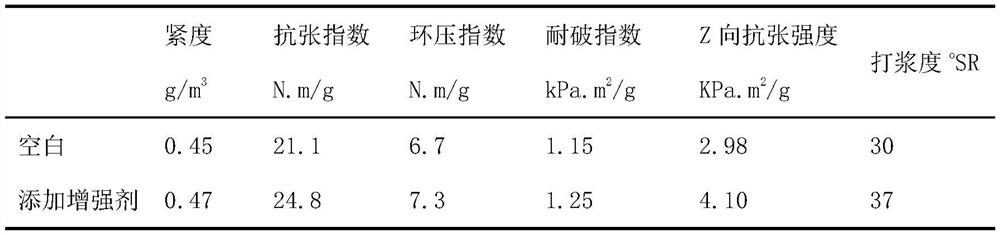

Embodiment 2

[0032] Cut the air-dried corn stalks into 2-3cm pieces, and process them in a rotary cooker with a solid-to-liquid ratio of 1:8, a maximum temperature of 160°C, and a holding time of 50 minutes. The processed raw materials are separated from solids and liquids and washed clean. Then, the treated raw material is mechanically treated with a disc refiner, and the refining concentration is 5%, so as to obtain high-yield pulp of corn stalks. Sieve with a 200-mesh sieve at a concentration of 1%, and the part that passes through the sieve is the parenchyma cell component. A high-shear emulsification machine was used to process the fine component suspension with a concentration of 1% at 10,000 rpm for 10 minutes to obtain parenchyma cells modified by high-shear emulsification. The raw material of waste paper pulp is domestic old corrugated box (OCC). The modified parenchyma cells are mixed with waste paper pulp. The amount of parenchyma cells is 10% (mass ratio, relative to dry waste ...

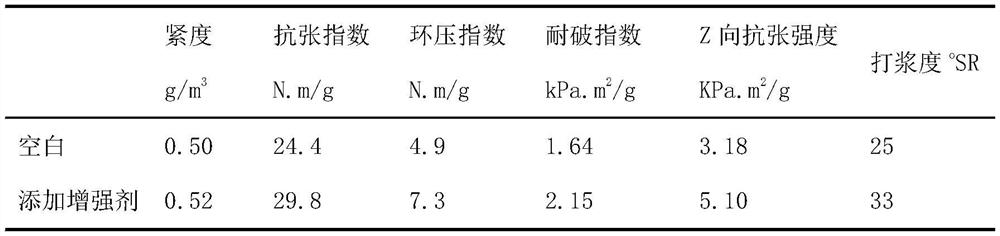

Embodiment 3

[0036] The air-dried wheat straw is cut into 2-4cm grass sections, and processed in a rotary cooker with a solid-to-liquid ratio of 1:4, a maximum temperature of 170°C, and a holding time of 40 minutes. The processed raw materials are separated from solid and liquid and washed clean. Then, the treated raw material is mechanically treated with a disc refiner, and the refining concentration is 25%, so as to obtain high-yield pulp. Sieve with a 100-mesh sieve at a concentration of 1%, and the part that passes through the sieve is the parenchyma cell component. A high-pressure homogenizer was used to process the parenchyma cell suspension with a concentration of 1% under a pressure of 80 MPa for 20 minutes to obtain high-pressure homogenized modified parenchyma cells. The raw material of waste paper pulp is domestic old corrugated box (OCC). The modified parenchyma cells are mixed with waste paper pulp. The amount of parenchyma cells is 4% (mass ratio, relative to dry waste paper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com