Motor front-mounted type submersible tubular pump

A front-end, tubular-flow pump technology, applied in the direction of circulation pumps, cross-flow pumps, non-variable pumps, etc., can solve the problems of low efficiency of submersible axial flow pumps, hindering the smoothness of pumping water flow, and large volume of submersible motors , to avoid water blocking, improve unit efficiency and reduce volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

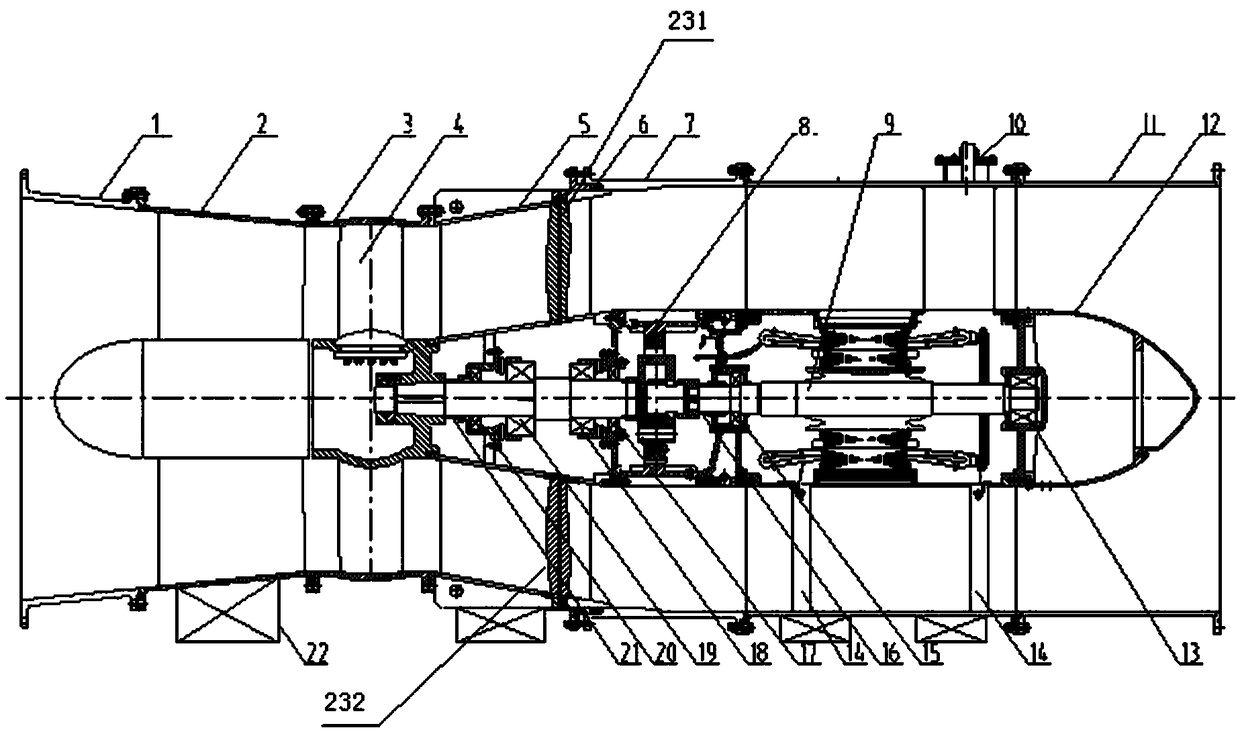

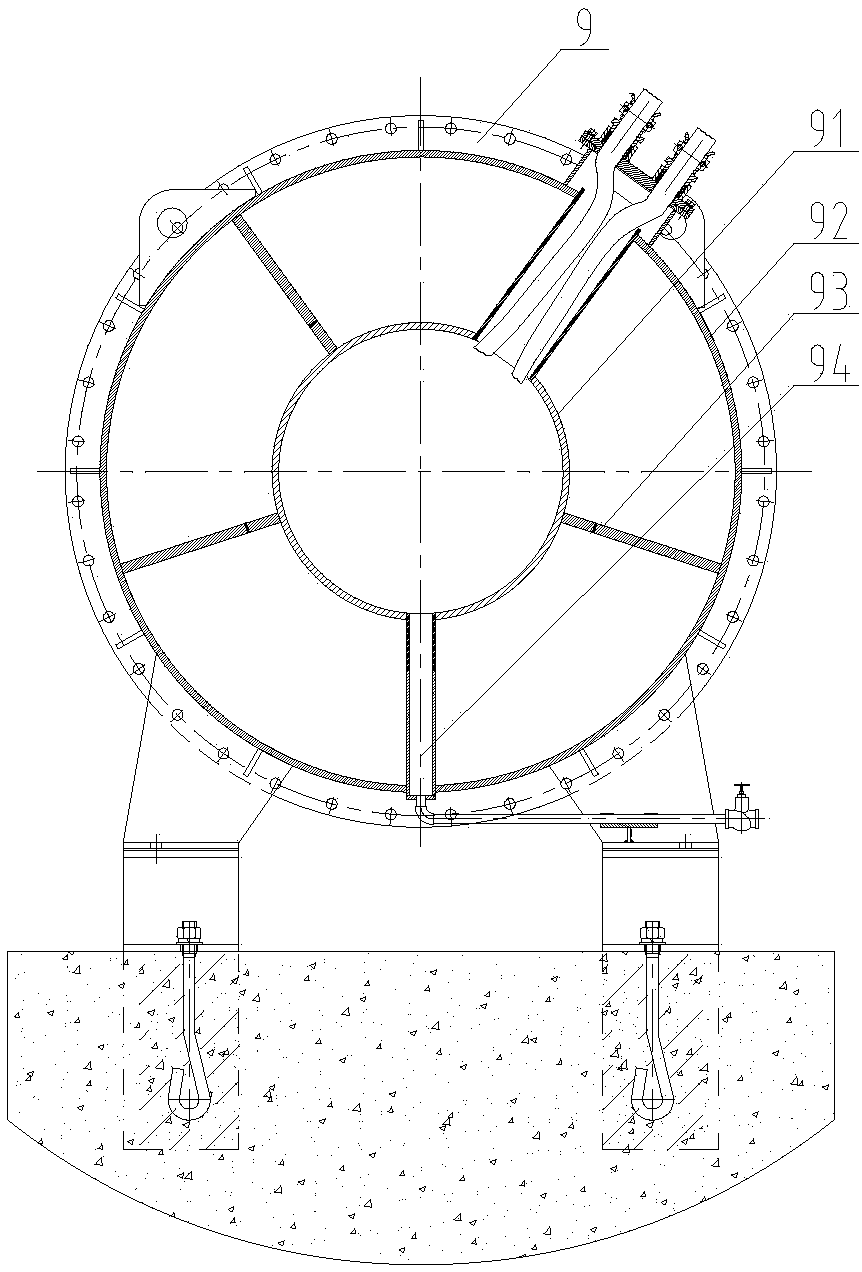

[0017] Such as figure 1 , 2 As shown, a motor front-mounted submersible tubular pump includes a diffuser tube 1, a guide vane body 2, an impeller casing 3, an impeller assembly 4, a water inlet trumpet tube 5, a flexible seal 6, a short seal tube 7, and a planetary gear reducer 8, submersible motor 9, outlet device 10, water inlet pipe 11 and diversion cap 12; the water pump and the two main shafts of the submersible motor 9 are connected through a planetary gear reducer 8; the submersible motor 9 is arranged at the front of the impeller assembly 4 , the guide vane body 2 is located at the rear of the impeller assembly 4, a short sealing tube 7 is arranged between the submersible motor 9 and the guide vane body 2, and the seal between the guide vane body 2 and the submersible motor 9 is sealed by a flexible seal 6 and a pressure plate, This kind of seal is a flexible seal, which avoids over-positioning of the over-current housing.

[0018] Two sets of radial bearings 13 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com