Electro-hydrostatic actuator with load compensation and high position precision and control method

A technology of load compensation and electrostatic fluid, which is applied in the direction of fluid pressure actuation device, fluid pressure actuation system test, servo motor components, etc., to simplify the control process, improve precision and dynamic performance, and achieve the effect of no impact connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

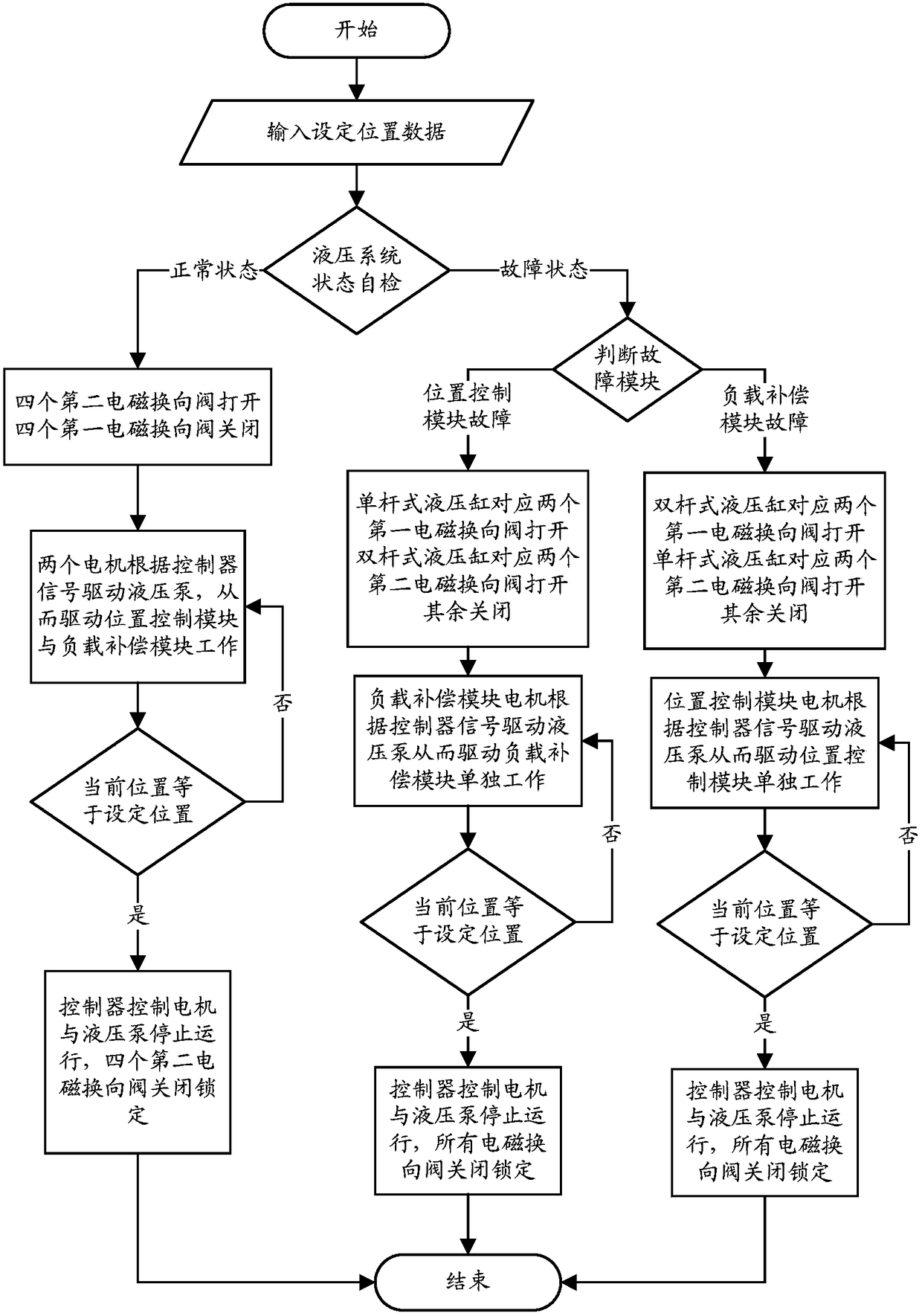

[0048] In order to make the present invention more comprehensible, a preferred embodiment is now described in detail with accompanying drawings as follows.

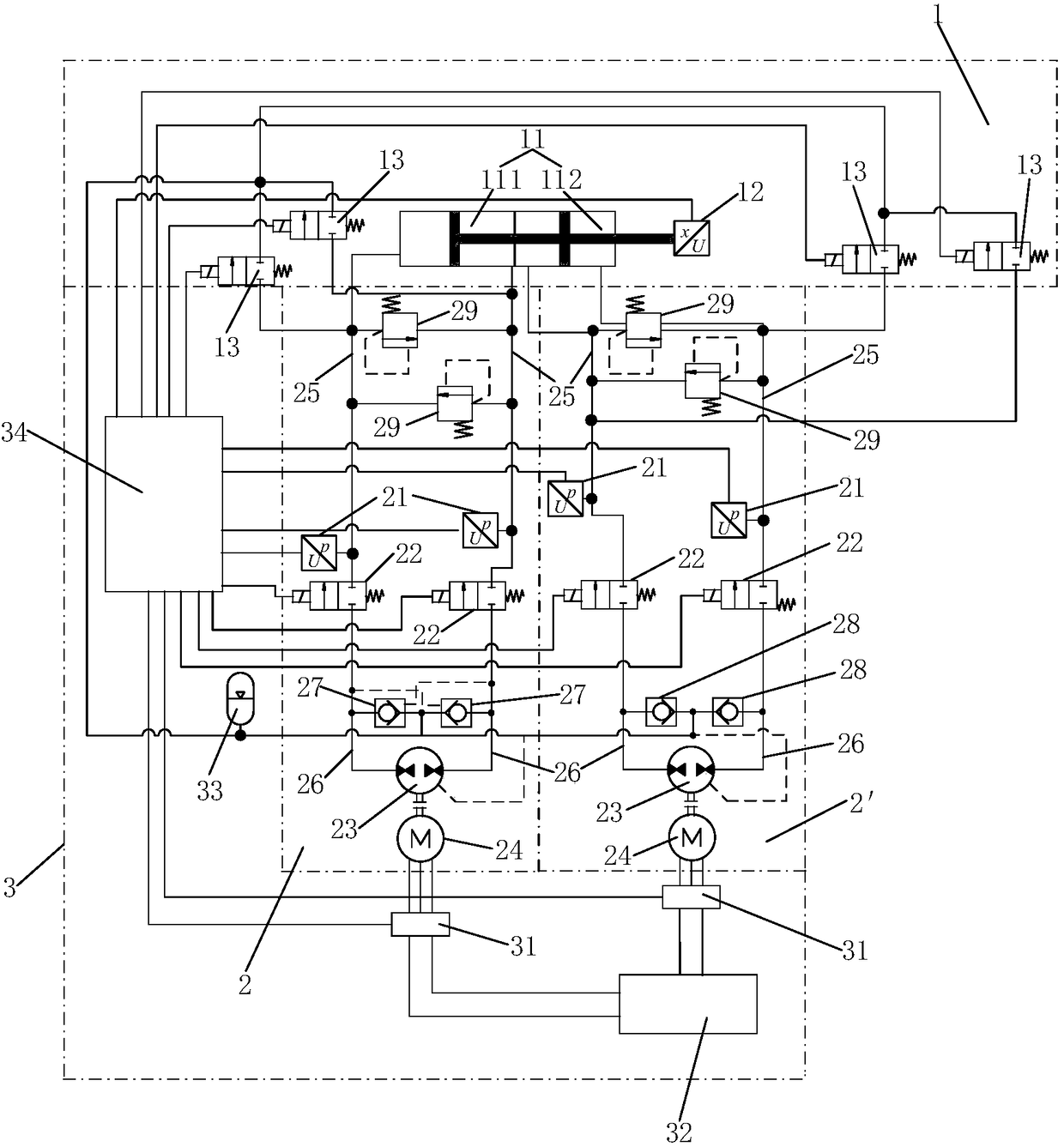

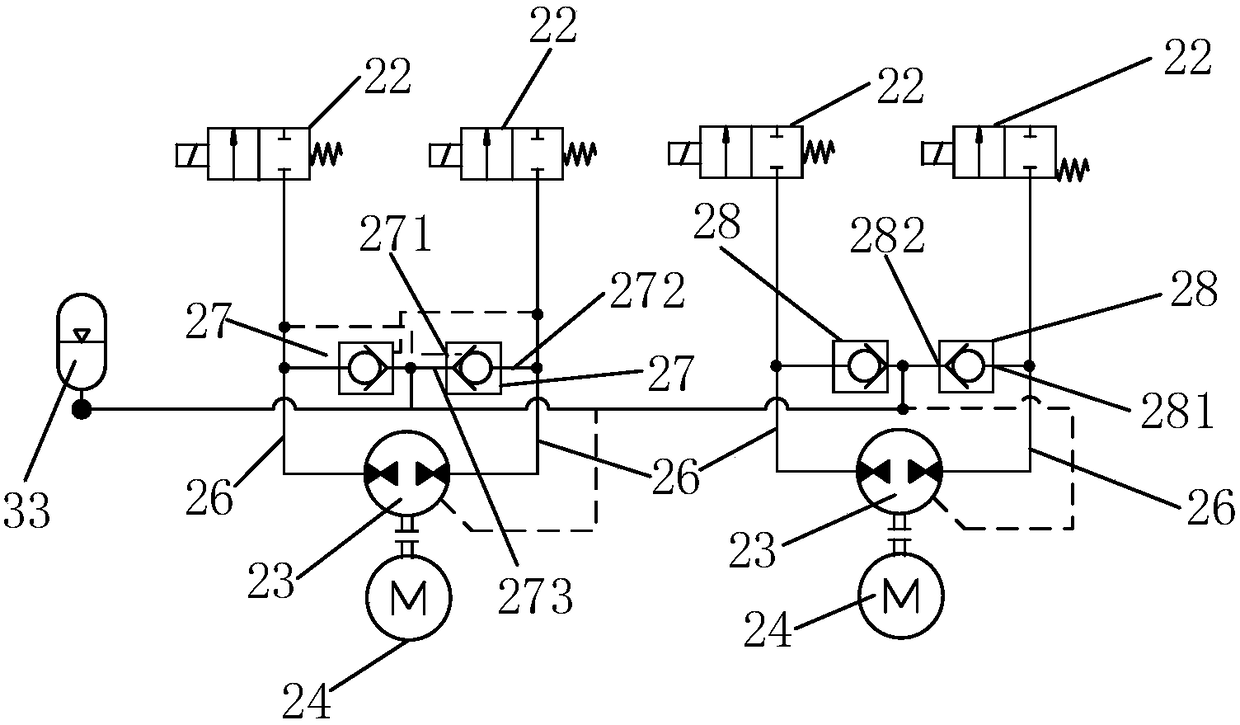

[0049] Such as figure 1 and figure 2 As shown, an electrostatic fluid actuator with load compensation and high position accuracy of the present invention includes a hydraulic control module 1, a position control electrohydrostatic actuator module 2, a load compensation electrohydrostatic actuating module 2' and An electrical control module 3;

[0050] The hydraulic control module 1 includes a compound hydraulic cylinder 11, a displacement sensor 12 and four first electromagnetic reversing valves 13, the displacement sensor 12 is installed on the piston end of the compound hydraulic cylinder 11, and the four The oil inlets of the first electromagnetic reversing valve 13 are connected to the oil inlets of each chamber of the composite hydraulic cylinder 11 in one-to-one correspondence;

[0051] Both the position control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com