FBG packaging structure capable of monitoring soil-body small deformation and packaging method

A technology of encapsulation structure and encapsulation method, which can be applied to measurement devices, optical devices, instruments, etc., can solve problems such as coordinated deformation, easy slippage of soil and optical fibers, etc., to increase friction coefficient, increase stiffness, and improve coordinated deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

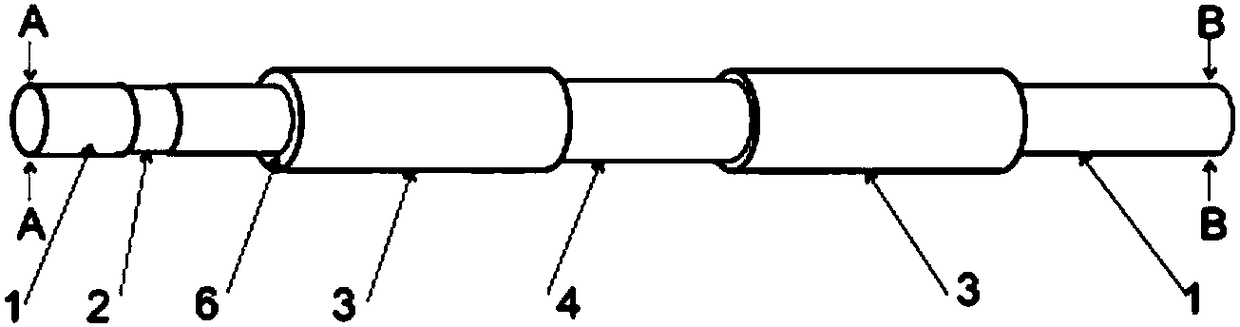

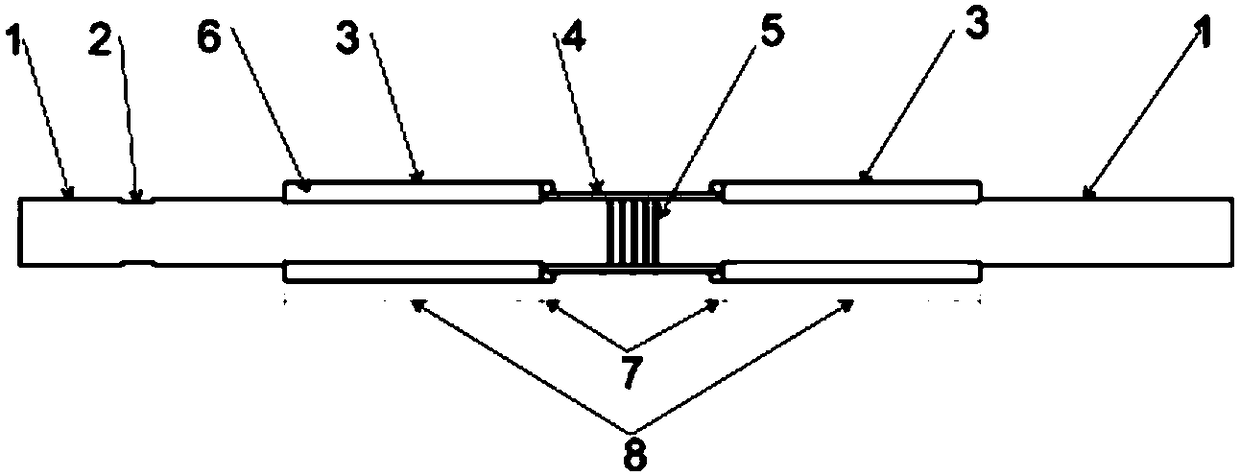

[0028] The present invention will be further explained below in conjunction with the accompanying drawings.

[0029] The principle of the invention is: because the FBG sensor is sensitive to strain, the FBG embedded in the soil to be measured can monitor the change of the soil strain at the embedded point according to the change of the FBG wavelength. The body is prone to relative sliding, and this effect is more obvious after encountering water. A thermoplastic tube with an outer diameter slightly larger than the optical fiber is selected to be fixed on both sides of the grating. As an enlarged end, the soil and the optical fiber can be effectively coupled together. The surface of the sleeve is ground to form a rough-surfaced thermoplastic tube. In the sensing element area of the FBG sensor, a quartz tube with an outer diameter slightly smaller than the thermoplastic tube and an inner diameter larger than the optical fiber lead wire is used for protection, and the interfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com