Fastener-style steel pipe template support system design method

A formwork support and design method technology, applied in the direction of design optimization/simulation, calculation, special data processing applications, etc., can solve problems such as inconsistent conclusions, calculation results that cannot reflect the actual situation, limited research on structural measures, etc., to achieve improvement The effect of stable bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

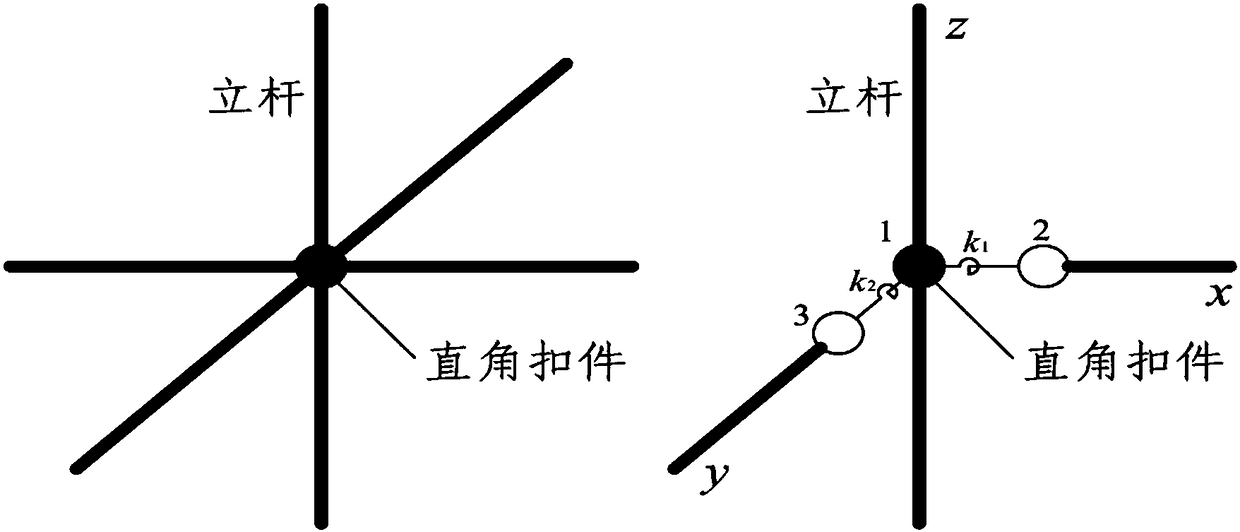

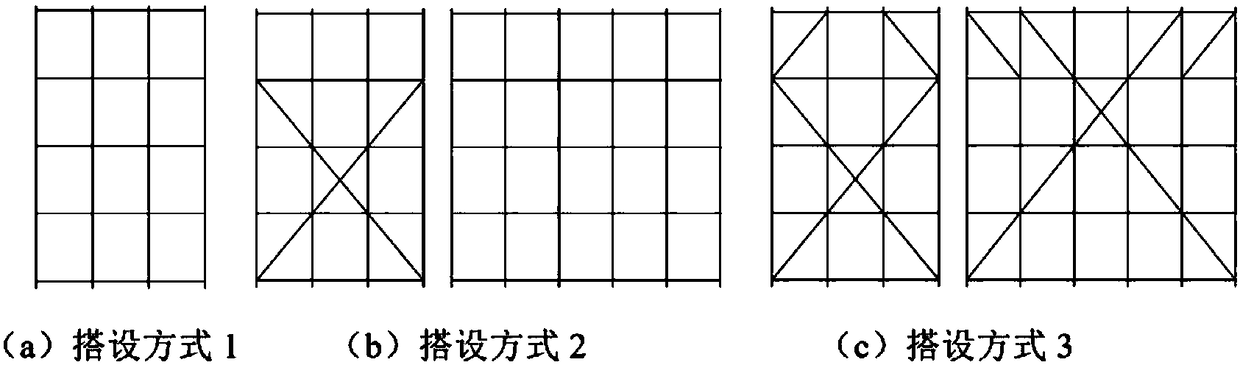

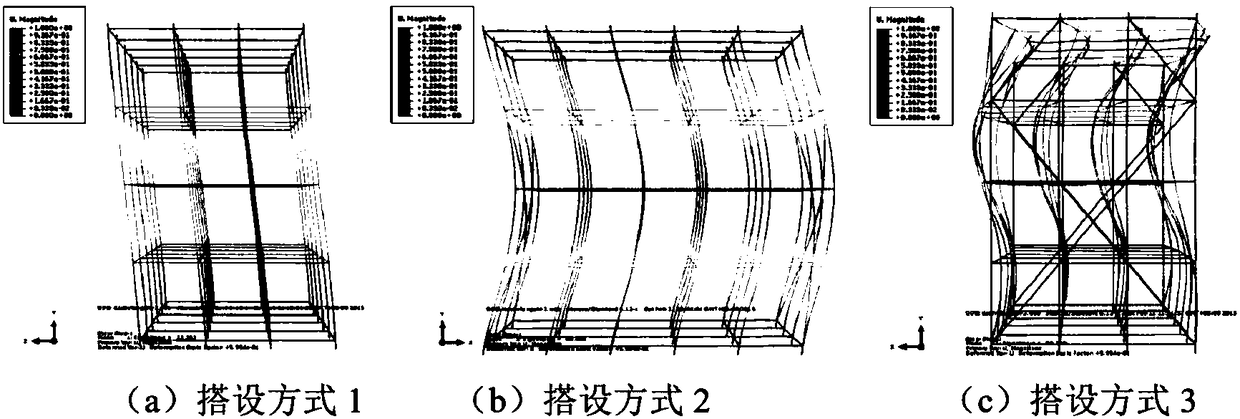

[0090] Through the ABAQUS finite element software, the mechanical performance of the fastener-type steel pipe formwork support system is analyzed as a whole. According to the provisions of relevant erection parameters in Safety Code (JGJ 162-2008), the analysis model of typical support system is selected as follows: Figure 4 As shown, the distance between vertical and horizontal poles l a = l b = 1.2m, the step distance of the horizontal bar h = 1.5m, the length of the vertical bar beyond the top horizontal bar is a = 0.2m, the height of the sweeping bar is d = 0.2m, and the rotational stiffness of the right-angle fastener is taken as R k =30kN·m / rad, the vertical scissor braces are arranged around the supporting system, and are set in two directions.

[0091] 1. Influence of fastener tightening torque T

[0092] Figure 5 The influence curve of fastener tightening torque on the stable bearing capacity of the support system. It can also be seen from the figure that when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com