High-power-density motor

A high power density, collector ring technology, applied in synchronous motors with stationary armatures and rotating magnets, electromechanical devices, electrical components, etc. Problems such as poor heat dissipation capacity of the motor, to achieve the effect of improving heat dissipation capacity, reducing contact resistance, and high torque density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

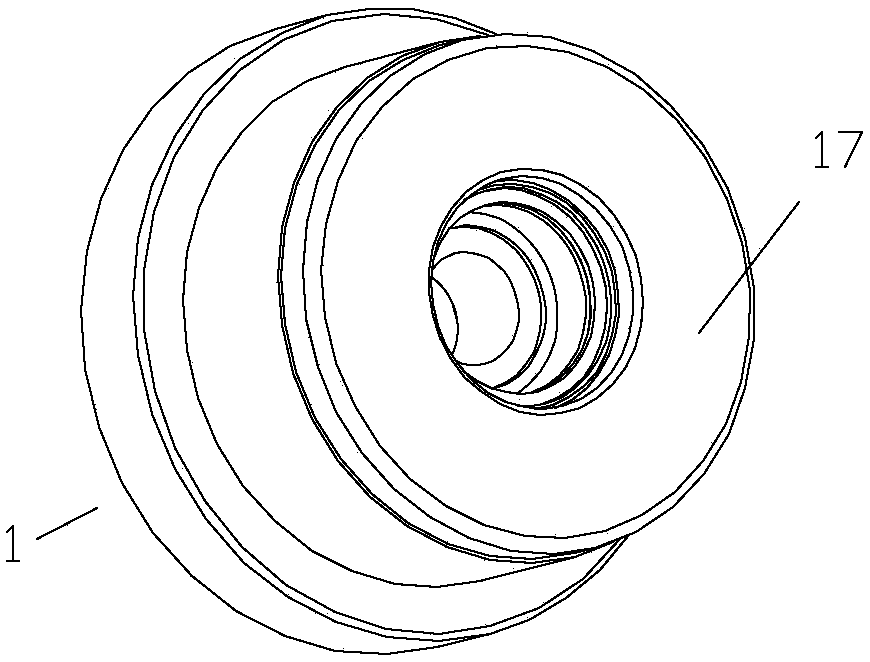

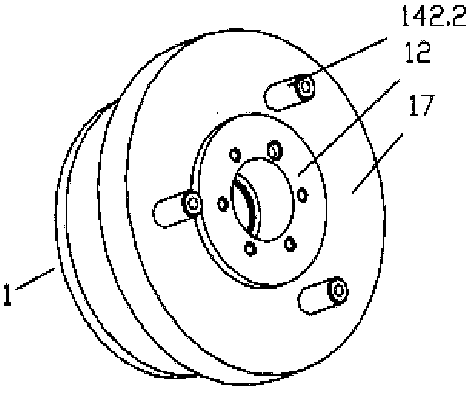

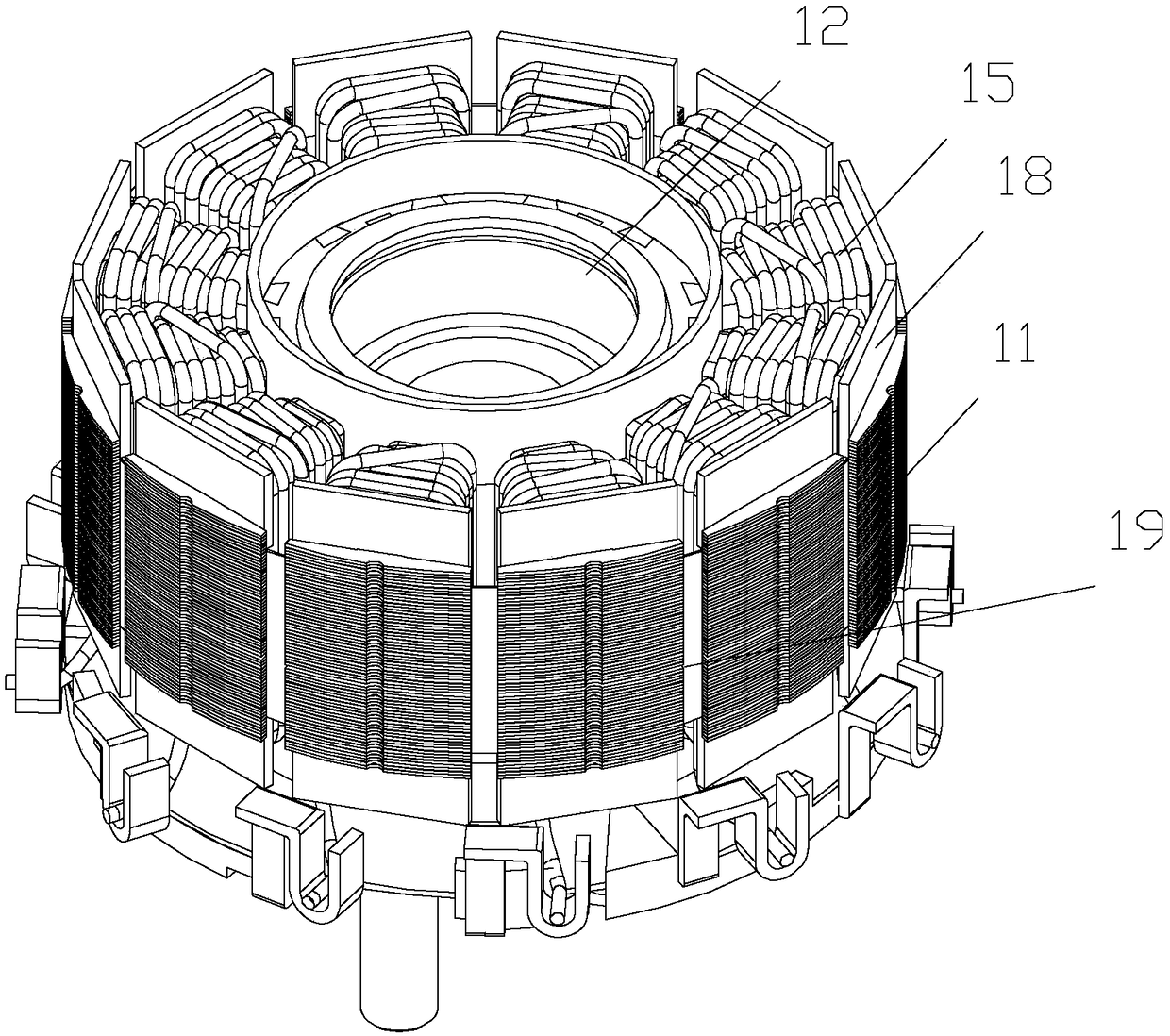

[0037] The invention discloses a permanent magnet synchronous motor structure with high power density, which includes a stator assembly 1 and a rotor 2 . The stator assembly 1 includes a stator core 11, an insulating frame 18, a stator winding 15 wound on the stator core and the insulating frame, a stator bushing 12, an end collector ring 14 and an end insulating plate 13 made of insulating material. The stator core 11 is wound with an enameled wire to form a stator coil, and the coils on two adjacent teeth form a group of stator windings 15, and two taps are respectively drawn from the two ends of each group of windings.

[0038] Such as Figure 7 The stator bushi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com