Breaking collection system

A collection system and crushing cavity technology, applied in the field of label manufacturing, can solve the problems of increased cost, confusion, laborious and time-consuming management, etc., and achieve the effects of reducing production downtime loss, improving production efficiency, and convenient management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

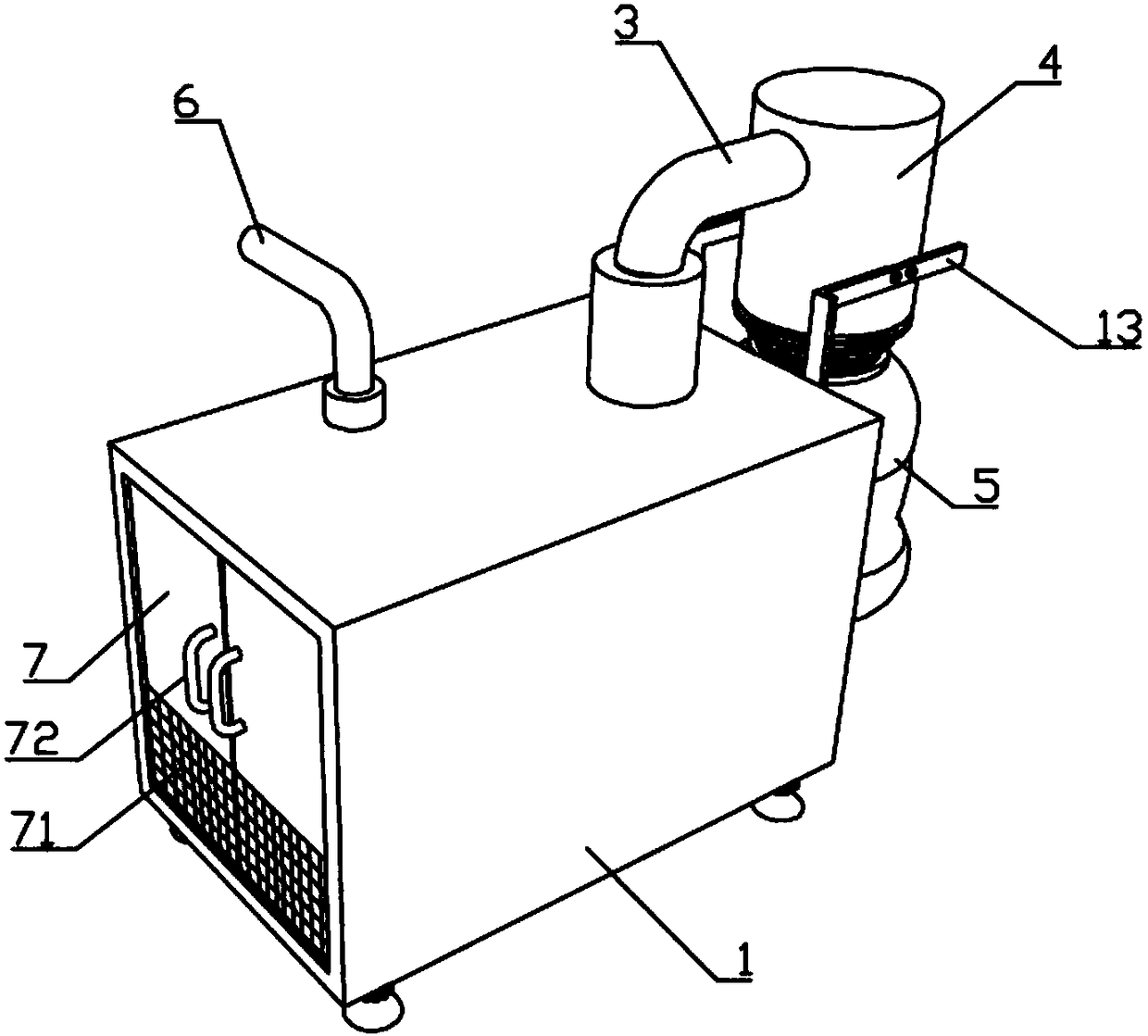

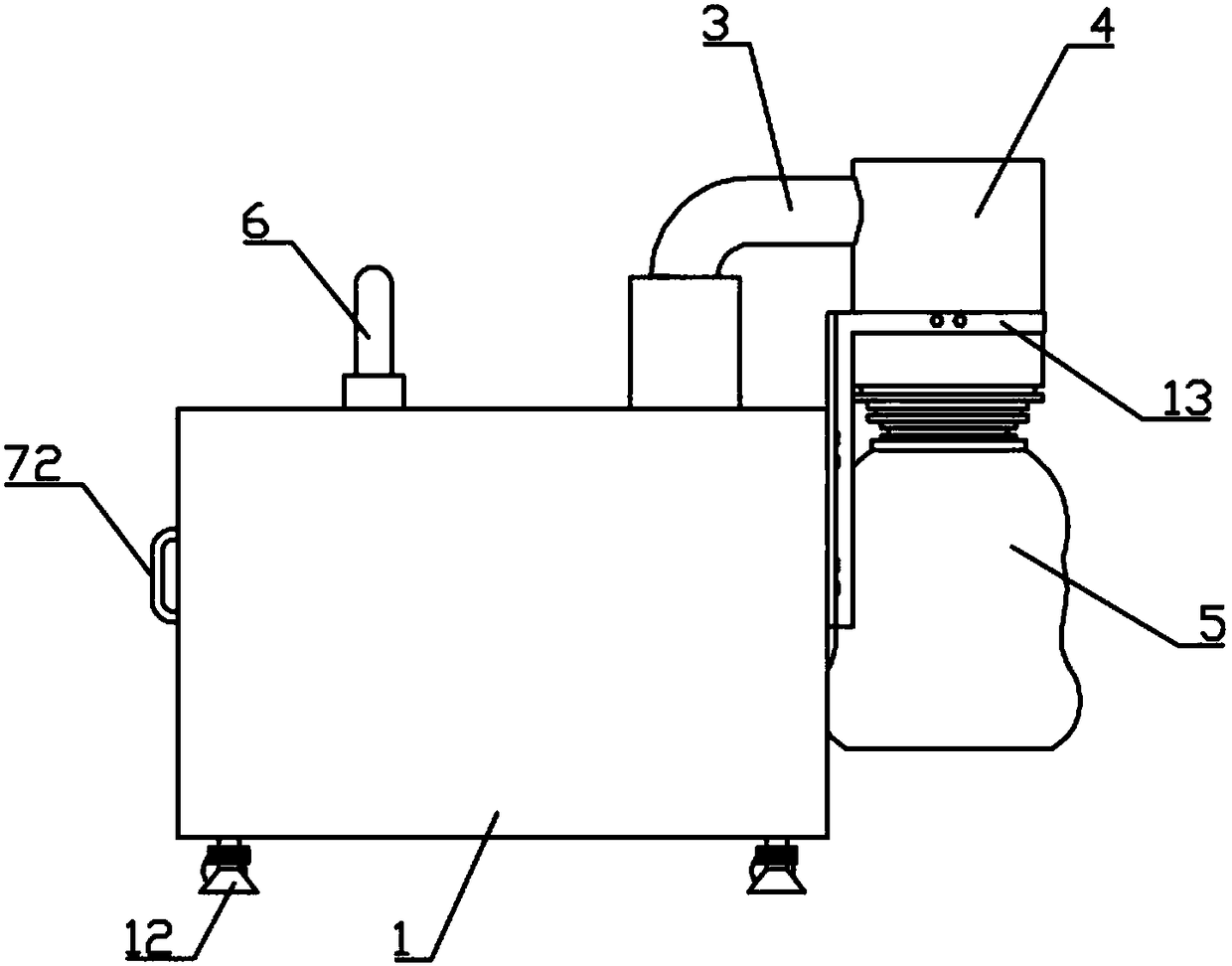

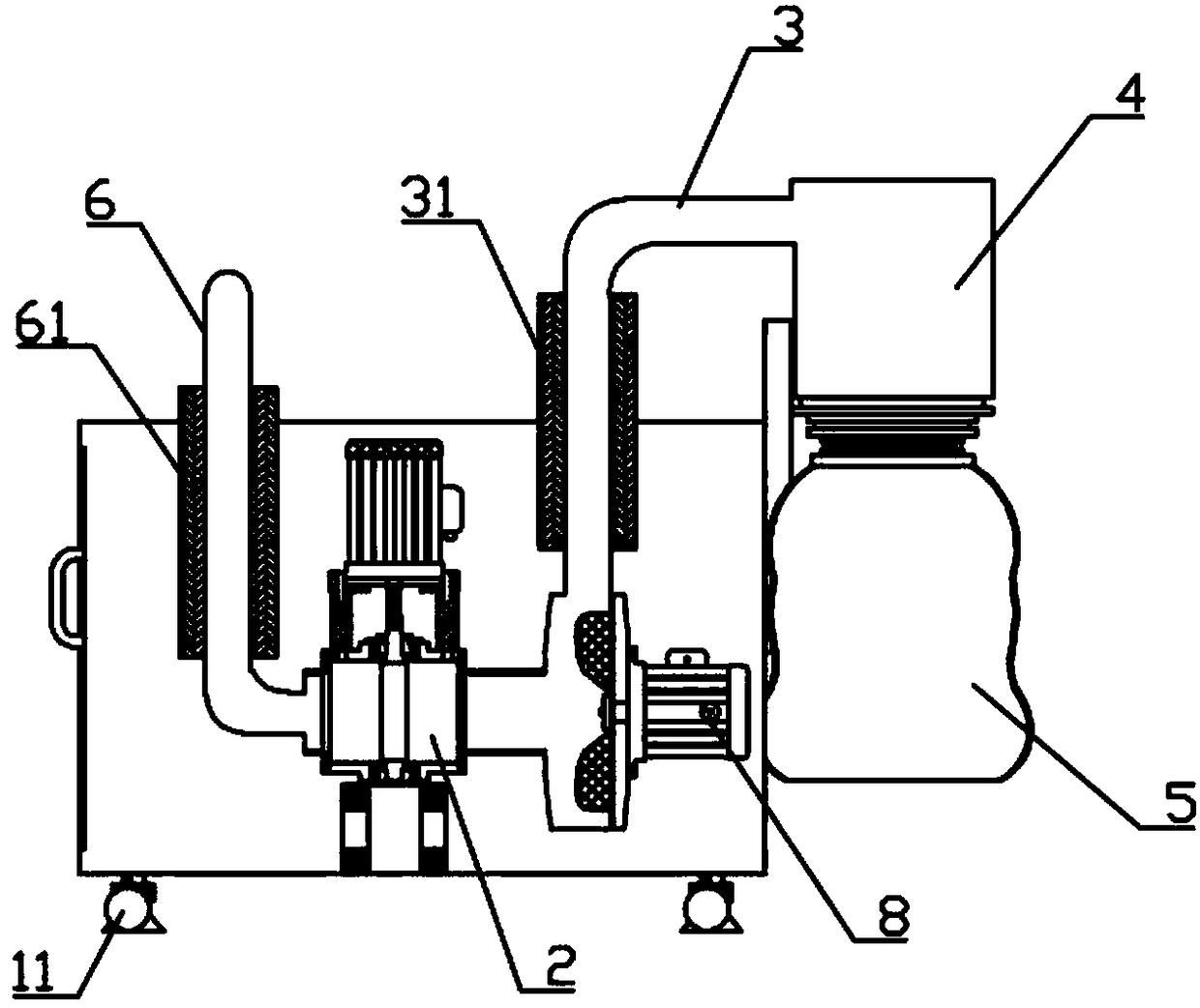

[0031] Such as Figure 1 to Figure 8 As shown, the crushing and collecting system of the present invention includes a casing 1, a crusher 2 and a blower fan 8 are arranged in the casing 1, a feed pipe 6 is provided at the left end of the upper end surface of the casing 1, and the lower end of the feed pipe 6 goes deep into the casing 1. Inside, the crusher 2 includes a motor 21 and a crushing chamber 23. The motor 21 is set directly above the crushing chamber 23 and is set upside down. The lower end of the power output shaft of the motor 21 penetrates into the crushing chamber 23 and is provided with a rotating shaft 22. , two blades 27 are integrally arranged on the rotating shaft 22, the blades 27 are bolted to a movable blade 28, one side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com