Overall construction method for belt straining beam dumbbell-shaped pile cap steel hoisting box cofferdam under complex sea conditions

An integral construction, steel hanging box technology, applied in infrastructure engineering, protection devices, construction, etc., can solve problems such as high cost and difficult beam back cover, save construction period and procedures, and speed up construction progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

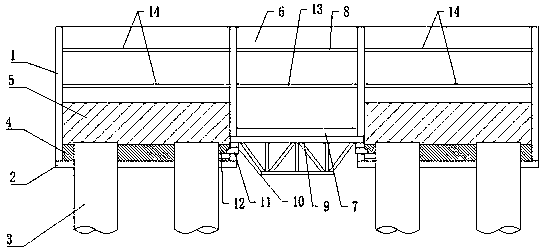

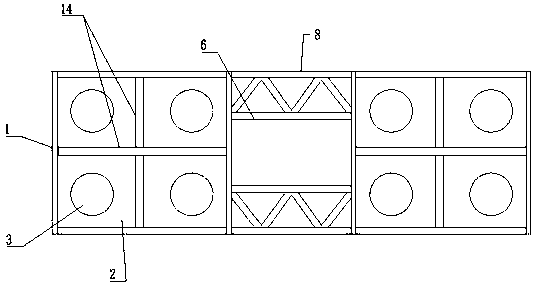

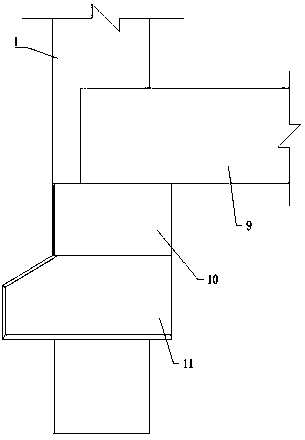

[0034] refer to Figure 1-4 The overall construction method of steel suspension box cofferdam with tie-beam dumbbell-shaped cap under complex sea conditions shown includes two symmetrically arranged steel suspension boxes. The concrete layer 4, the cap layer 5 and four steel casings 3 evenly distributed on the bottom plate, two fish-belly truss beams 9 are arranged between the two steel hanging boxes, and the fish-belly truss beams 9 A height difference adjustment block 10 is provided under each of the two ends of the height difference adjustment block 10, and a pair of two-way corbels 11 are arranged under the height difference adjustment block 10, and the two-way corbels 11 are welded on the wall plate 1, and are connected with the The wall panels 1 are processed and formed together, and the front end of the two-way corbel 11 is poured into the inside of the sealing layer 4, and the tail end extends to the outside of the wall panel 1. The steel casing 3 is welded with a supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com