Flame-retardant and explosion-proof ammunition box

A technology for flame-retardant and explosion-proof ammunition boxes, which is applied in the field of ammunition packaging boxes and flame-retardant and explosion-proof ammunition boxes. It can solve the problems of fast heat conduction, short service life, and non-uniform implementation standards, so as to reduce the amount of metal parts and avoid heat conduction. Damage, avoid the effect of unstable stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

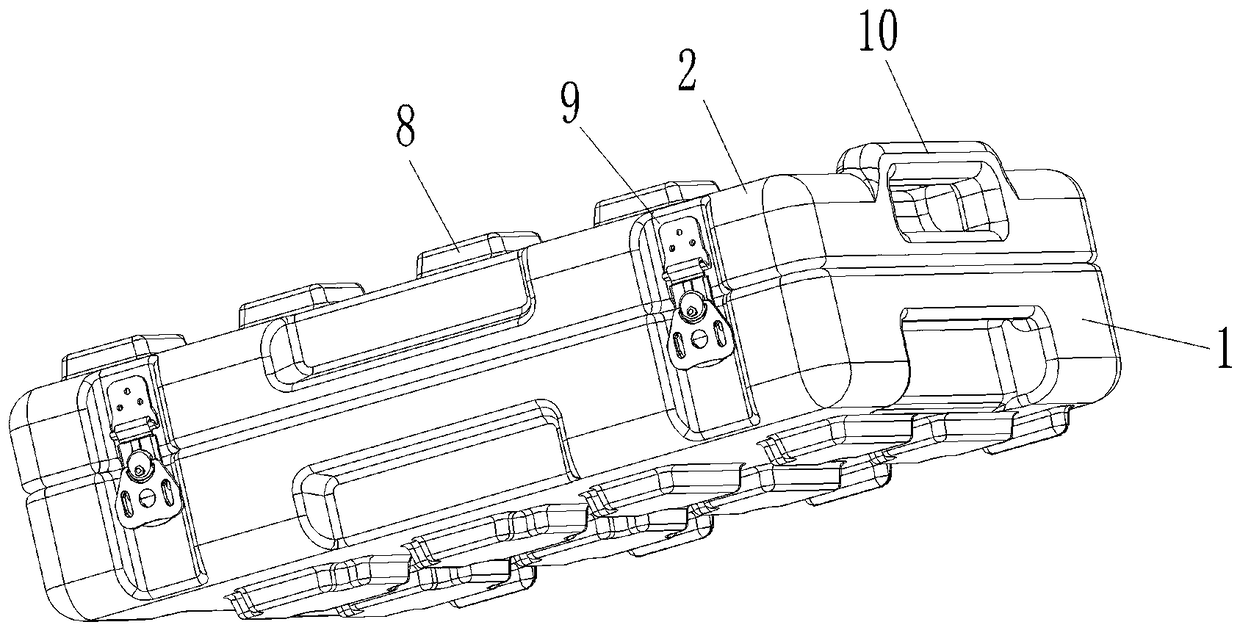

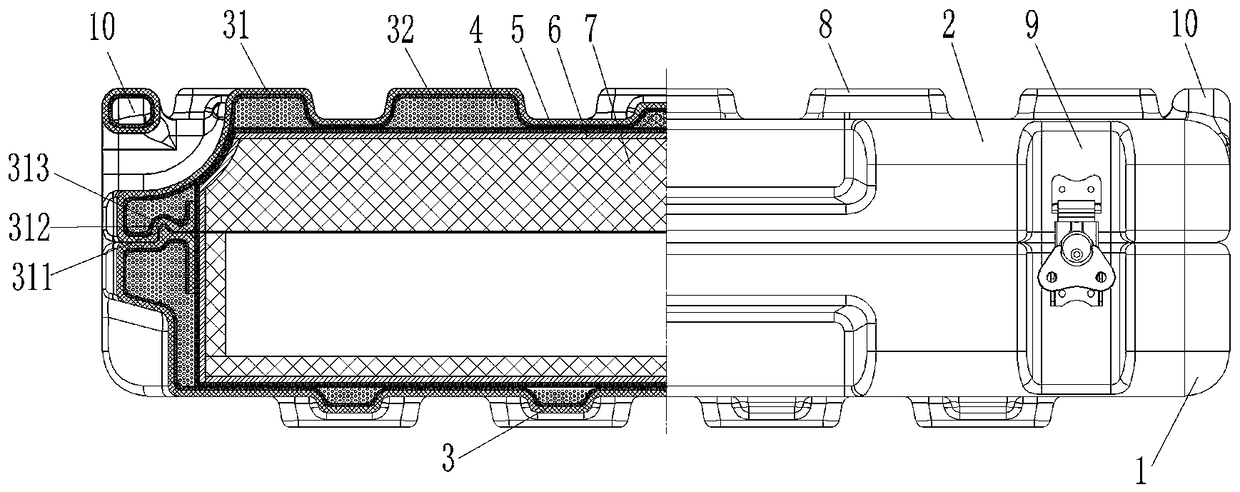

[0022] A flame-retardant and explosion-proof ammunition box, see the accompanying drawings, the box cover 2 is fastened on the box body 1, and the enclosed cavity has a foamed polyethylene vibration-damping mold shell that fits the box cover 2 and the inner wall of the box body 1 7. The vibration-damping mold shell 7 has a cavity matching the shape and specification of the ammunition, and the ammunition is placed in the cavity. The box body 1 and the box cover 2 both include a rotationally molded shell 3, a silica airgel thermal insulation filling layer 4, a silica airgel thermal insulation blanket 5 layers and an explosion-proof inner shell 6 of foamed aluminum from the outside to the inside.

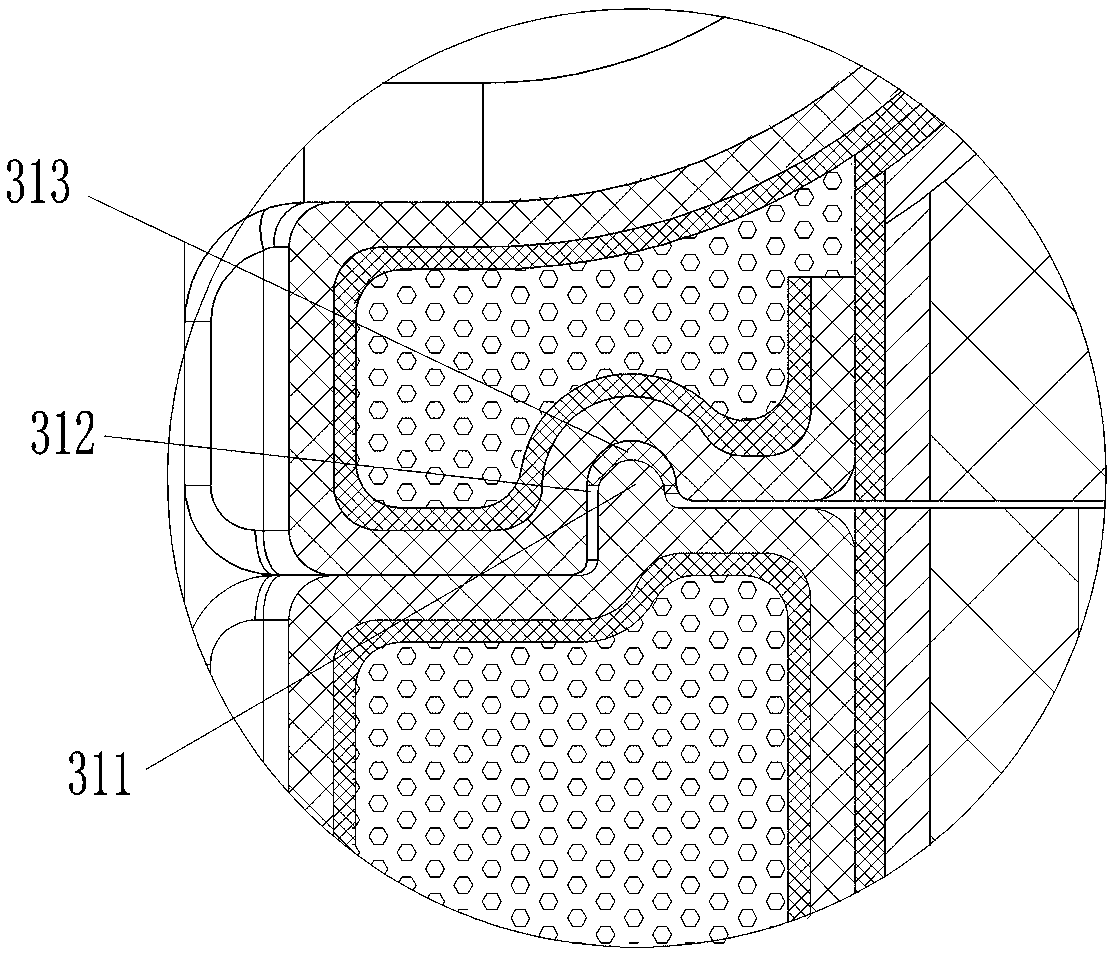

[0023] Both the rotomoulding casing 3 of the box body 1 and the box cover 2 include an impact-resistant outer layer 31 and a heat-insulating inner layer 32 formed of foamed polyethylene. The raw materials for the impact resistant outer layer include a flame retardant and a crosslinkabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com