Detection device for oil-stolen orifice of pipeline and detection method of center and diameter of oil-stolen orifice

A detection device and pipeline technology, which is applied in the field of pipeline detection, can solve the problems of undetectable, characteristic signal disappearance, high lift-off value, etc., and achieve the effect of improving accuracy, low cost and improving maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

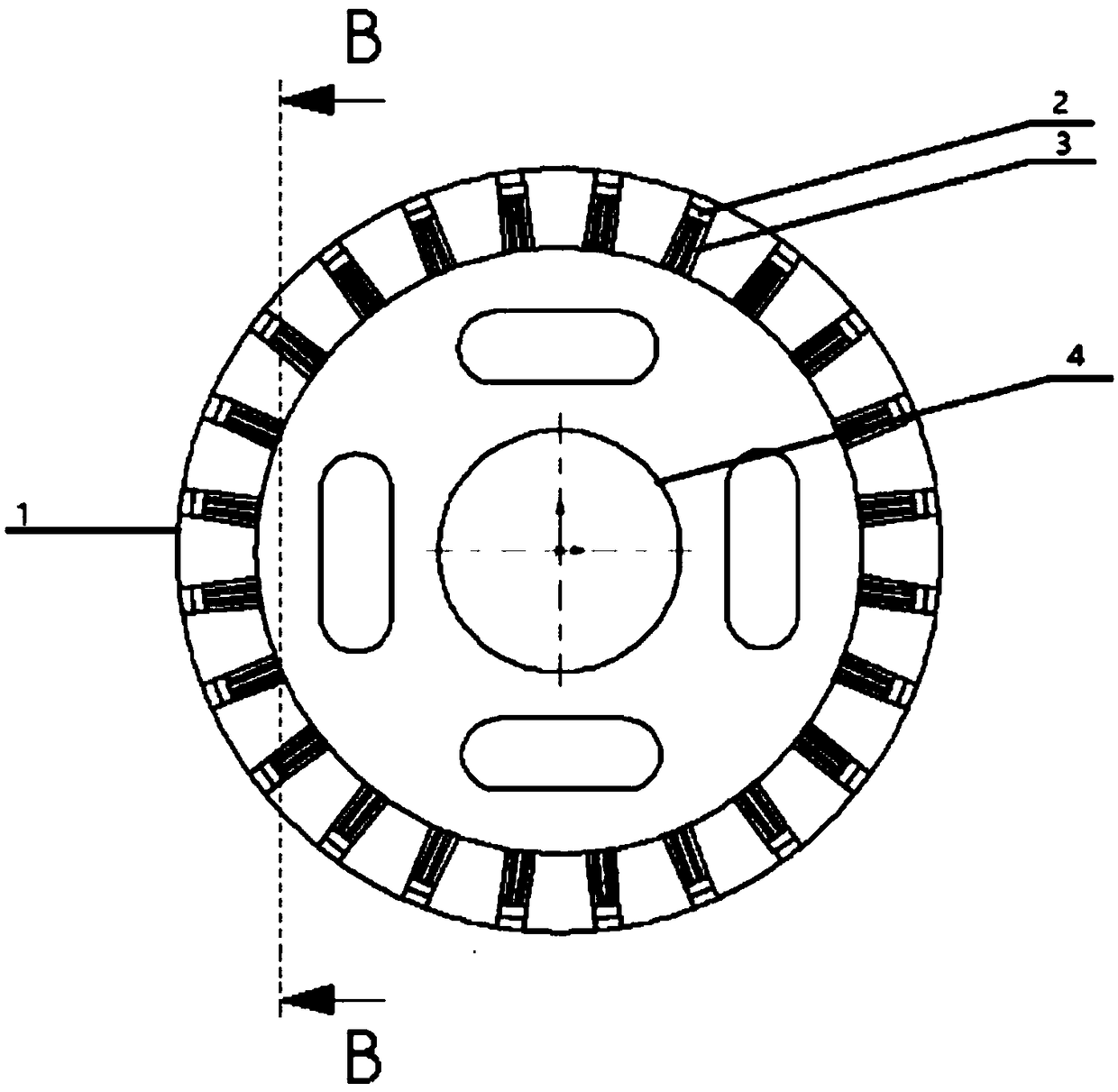

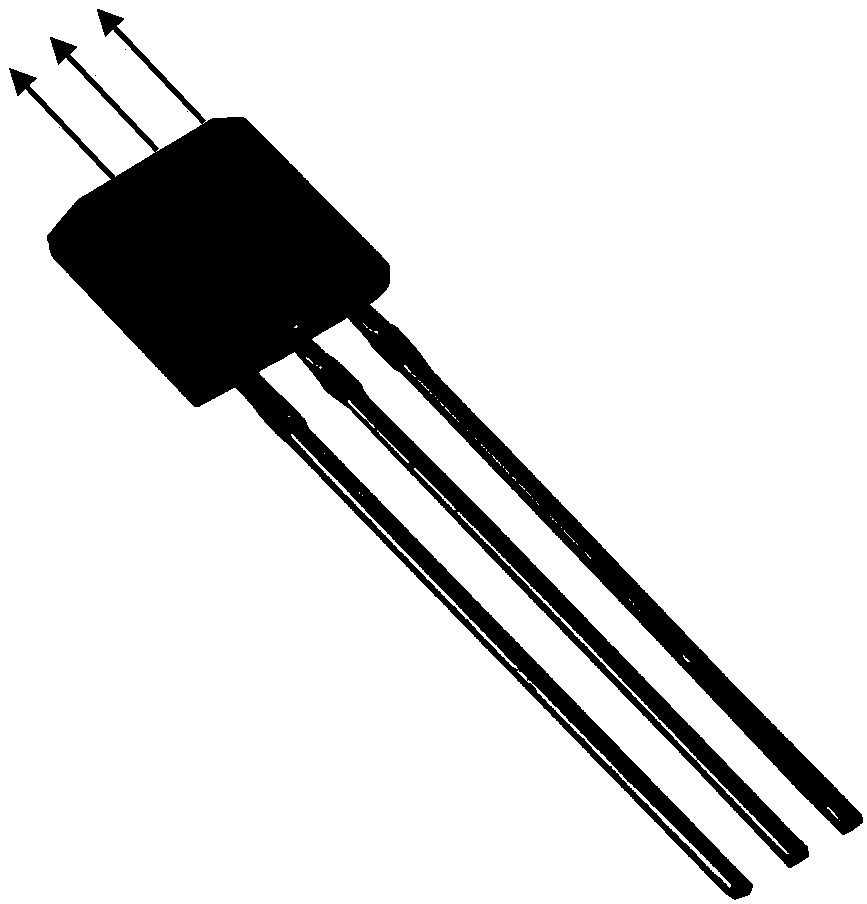

[0049] A detection device for pipeline oil stealing holes, see Figure 1-Figure 5 , the detection device includes: a detector 1 in the pipeline, a Hall element 2 and a magnet 5 are installed on the detector 1 in the pipeline (the embodiment of the present invention takes a cylindrical magnet 5 as an example for illustration, and during specific implementation, the embodiment of the present invention This is not limited), the model of the Hall element 2 used in this detection device is SS495A1, it has three pins, and its physical figure is as follows figure 2 shown.

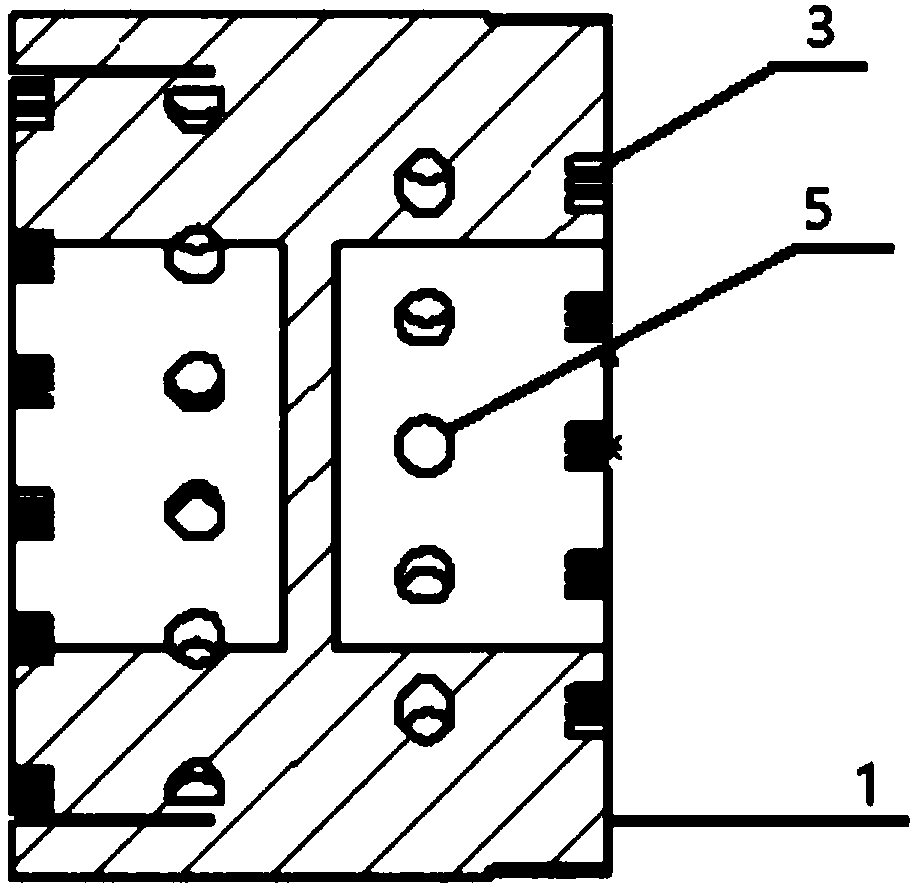

[0050] The front view and cross-sectional view of the detector 1 in the pipeline are as follows figure 1 and image 3 As shown: In order to avoid short circuit, each Hall element 2 is equipped with three pin slots 3 to respectively place the above three pins.

[0051] Such as image 3 As shown, the circular hole on the inner wall of the detector 1 in the pipeline is used to place a cylindrical magnet 5, and the...

Embodiment 2

[0054] The scheme in embodiment 1 is explained in principle below in combination with specific numerical values, see the following description for details:

[0055] The schematic diagram of the experimental device for the steel pipe test is shown in Figure 4 As shown: the detector 1 in the pipeline needs to be pushed forward by the pipeline fluid 13, and the wall of the device is attached to the wall of the pipeline.

[0056] In the in-pipe detector 1, the circumferential distance between the Hall elements 2 is 10-20mm, and the radius of the in-pipe detector 1 is equal to the inner diameter of the pipe.

[0057] The system block diagram of the detection device is as follows Figure 5 As shown: the battery 6 supplies power to the power management module 7, and the power supply to the Hall element 2 and the single-chip microcomputer 9 is realized through the power management module 7;

[0058] When the body of the pipeline detector 1 moves smoothly in the pipeline 11, under t...

Embodiment 3

[0064] Below in conjunction with concrete test, the scheme in embodiment 1 and 2 is carried out feasibility verification, see the following description for details:

[0065] The magnetic field signal detected by pushing the in-pipeline detector 1 into the pipeline 11 is as follows: Figure 7 shown.

[0066] Since the characteristic signal of the magnetic field of the oil stealing hole 12 has been determined, it can be distinguished from the test results that the Hall elements 22 and 23 just pass under the oil stealing hole 12, and the Hall element 21 and Hall element 24 just pass through the oil stealing hole. 12 pipe walls.

[0067] The size of the oil stealing hole 12 can also be estimated by the distance between the Hall element 21 and the Hall element 24 during field experiments, which is conducive to development and verification, that is, it is determined that the oil stealing hole 12 found is exactly the one detected by the detection device. oil hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com